A successful building automation system installation doesn't start with pulling wires or mounting sensors. It begins much earlier, with a solid plan rooted in a deep understanding of the building itself, the people in it, and what you’re actually trying to achieve. This groundwork is what separates a smooth, effective deployment from one that’s riddled with costly delays and headaches down the road.

Laying the Groundwork for a Smart Building

Jumping straight into picking out hardware without a detailed blueprint is a recipe for disaster. A proper BAS installation demands meticulous planning, starting with a thorough discovery phase. This is where you set the stage for every decision that follows.

Conducting a Thorough Site Survey

Your first real move is to get boots on the ground for a physical site survey. This isn't just a quick walkthrough; it's an investigative deep dive. You need to map out the building's current mechanical, electrical, and plumbing (MEP) systems with an expert eye. What’s the age and condition of the HVAC units? How are the lighting controls set up? What security systems are already in place?

This is your chance to spot potential roadblocks early. For example, if you find an ancient HVAC system with zero digital control points, you know you’ll need to budget for new actuators or maybe even a full unit replacement. It's also when you'll assess network closet space and existing cable pathways, which will heavily influence whether a wired or wireless approach makes more sense.

Aligning Key Stakeholders

A new BAS touches nearly every department, so getting everyone on the same page from day one is non-negotiable. This often means facilitating conversations between groups that rarely talk technology together.

- Facility Managers: Their world is daily operations and maintenance. They need a system that makes their job easier, sends clear alerts, and doesn't create more problems than it solves.

- IT Teams: They're focused on network security, bandwidth, and how this new system will play with the existing IT infrastructure. They’ll have tough questions about network access and security protocols.

- Finance Department: This group is all about the bottom line. They need to see the initial investment, projected energy savings, and a clear return on investment (ROI).

- End-Users: Whether they’re office workers or residents, the people in the building just want to be comfortable. Their feedback on temperature, air quality, and lighting can be invaluable for defining your goals.

Getting these stakeholders together helps define what a "win" actually looks like. Is the primary driver a 20% reduction in energy costs, or is it finally achieving a consistent temperature across all floors to keep everyone happy?

To keep this critical planning phase on track, it helps to formalize the process. This table outlines the key milestones you'll need to hit before any hardware is ordered.

Key Pre-Installation Planning Milestones

| Milestone | Key Objective | Primary Stakeholders Involved |

|---|---|---|

| Site Survey & Audit | Document all existing MEP, electrical, and network infrastructure. | Facility Managers, BAS Integrator, IT Team |

| Stakeholder Kickoff | Align all departments on project goals, expectations, and potential impacts. | All (Facilities, IT, Finance, End-User Reps) |

| Goal Definition | Translate business needs into specific, measurable BAS objectives (e.g., reduce energy use by 15%). | Finance, Facility Managers, Executive Leadership |

| Scope Finalization | Create a detailed document outlining what is and is not included in the project to prevent scope creep. | BAS Integrator, Project Manager, Finance |

| Protocol Selection | Decide between open (BACnet, Modbus) and proprietary systems based on long-term goals. | IT Team, BAS Integrator, Facility Managers |

Hitting each of these milestones ensures that everyone is working from the same playbook, which is the best way to avoid costly surprises later on.

Defining Project Goals and Scope

With everyone's input, you can move from vague ideas to concrete, measurable objectives. "Improve efficiency" is a nice thought, but it’s not a goal. A real goal is something like, "Reduce HVAC runtime by 15% during off-peak hours" or "Automate lighting schedules to sync with real-time occupancy data."

A well-defined scope is your project's North Star. It guides every technical decision, prevents scope creep, and ensures the final system delivers on its promises by tying every feature back to a specific, agreed-upon business outcome.

This is also the stage for getting into the technical weeds. For the HVAC system, for instance, you need to know how to handle specifics like calculating HVAC size for your home or commercial space to ensure the equipment is specified correctly. This nitty-gritty detail turns your budget from a rough guess into a reliable forecast.

Open vs. Proprietary Protocols: A Critical Choice

One of the most important decisions you'll make early on is choosing between open and proprietary communication protocols. It’s a choice with long-term consequences.

An open protocol, like BACnet or Modbus, is like speaking a universal language. It allows devices from all different manufacturers to communicate with each other seamlessly. This is huge because it gives you flexibility and prevents you from being locked into a single vendor for the life of your building.

A proprietary system, on the other hand, uses a language only its own components understand. While this can sometimes offer tight integration between that one brand’s devices, it severely limits your options for future upgrades or replacements. For any modern building automation system installation aimed at long-term scalability, an open protocol is almost always the way to go.

The demand for these smarter, more efficient buildings is exploding. The global building automation system market was valued at around $92.2 billion in 2024 and is projected to hit $191.13 billion by 2030. This incredible growth just highlights how important it is to make future-proof decisions today.

Choosing Your System Hardware and Architecture

Once you've nailed down your project goals, it's time to get into the nuts and bolts: the physical hardware that will bring your smart building to life. The components you select now will define your system's capabilities, its day-to-day reliability, and how easily it can grow with you. This isn't just a shopping trip for the latest tech; it’s about making smart, strategic decisions that match your building's unique needs.

You're essentially building an ecosystem. It’s a balancing act between performance, compatibility, and of course, cost. For instance, a large hospital might need a heavy-duty, centralized Direct Digital Control (DDC) system with redundant controllers for its critical life-safety equipment. On the other hand, a flexible co-working space could be better served by a wireless mesh network of sensors and actuators that can be easily moved around as the floor plan changes.

The Core Components of a BAS

At its heart, any Building Management System (BMS) boils down to three key types of hardware. Each has a specific job in sensing the environment, thinking about what to do, and then acting on it.

- Controllers: These are the brains of the whole operation. They take in data from sensors, run it through pre-set logic, and then tell the actuators what to do. You'll find everything from massive central plant controllers to small, single-zone units.

- Sensors: Think of these as the system's eyes and ears. They’re out there measuring all the important variables—temperature, humidity, CO2 levels, whether a room is occupied, and how bright it is.

- Actuators: These are the muscles. When a controller gives a command, an actuator is the device that physically makes something happen. It might be opening a valve on a hot water pipe or adjusting a damper inside an air duct.

Getting how these three pieces work together is crucial. I’ve seen projects where the quality and placement of a single, inexpensive sensor dramatically affected the performance of a multi-million-dollar HVAC system. It all matters.

Decoding Communication Protocols and System Architecture

For all this hardware to play nicely together, it needs a common language. That’s where communication protocols like BACnet and Modbus come into the picture. Sticking with these open protocols is a non-negotiable for me, as it saves you from getting locked into a single manufacturer. You get the freedom to pick the best device for the job, no matter whose name is on the box.

Just as important is the system's architecture—the blueprint for how all your devices connect and communicate. This decision will ripple through everything from the initial installation headaches to long-term maintenance costs.

The architecture you design today determines the flexibility you'll have tomorrow. A well-planned, scalable architecture avoids premature obsolescence and ensures your investment remains valuable for years, adapting to new technologies and building needs.

You’ll generally run into three common architectural models:

- Centralized: One powerful main controller runs the whole show, with simpler devices in the field just reporting back. This is the go-to for big, complex facilities where having unified control is the top priority.

- Distributed: Here, the intelligence is spread out to smaller controllers located right next to the equipment they manage. This setup is more resilient; if one controller goes down, the rest of the building can often keep running without a hitch.

- Cloud-Based: Data gets funneled up to the cloud for heavy-duty processing, storage, and analysis. This unlocks incredible analytics and remote access but hinges on a rock-solid internet connection.

To tie all these diverse devices together, especially in a modern BAS, choosing the right IoT gateways for energy management systems is a critical piece of the puzzle. These gateways are the translators, bridging the communication gaps between different protocols and connecting your on-site hardware to the cloud.

Making Smart Hardware Choices

When you're comparing components, look past the price. You need to get into the weeds of the spec sheets. Check the operating ranges, power needs, communication ports, and especially the environmental ratings. A sensor built for a climate-controlled office will die a quick death in a hot, humid mechanical room.

Don't forget the network that connects everything. The integrity of your entire building automation system installation depends on the cabling that forms its backbone. For most wired systems, this means a solid, well-planned network infrastructure. To get a better handle on the fundamentals, our guide on what is structured cabling is a great resource for creating a network that’s both organized and reliable.

In the end, it’s all about creating a system that’s balanced and built to last. By focusing on open protocols, picking a scalable architecture, and really vetting every component, you’re laying a foundation that’s not just powerful today, but ready for whatever comes next.

Executing a Clean Physical Installation

This is where the rubber meets the road. Your blueprints are finalized, the hardware is on site, and it’s time to bring the system to life. Let me be blunt: a sloppy physical install will haunt you for years. It's the root cause of countless operational headaches, from mysterious signal drops to troubleshooting nightmares that drag on for days.

Getting the physical work right from the start is one of the most critical things you can do for the long-term health of your BAS. We're not just connecting wires here; we're building a system that's robust, serviceable, and professional from the inside out.

Mastering Low-Voltage Wiring and Cable Management

The low-voltage wiring is the central nervous system of your BAS, linking controllers to every sensor and actuator. While it’s not high-voltage, the quality of these runs is absolutely critical. Poorly installed cables are a magnet for signal interference, which leads to bad data and unreliable control.

Think of your cable pathways as the building’s arteries. They need to be clean, organized, and easy to trace. This means fighting the urge to take the shortest route. Always use dedicated cable trays or conduits, especially in the chaos of a mechanical room.

Here are a few hard-won best practices from the field:

- Separate Power and Data: This is non-negotiable. Never run low-voltage control wiring parallel to high-voltage lines in the same conduit. The electromagnetic interference (EMI) will corrupt your data signals and cause all sorts of erratic behavior.

- Use Proper Supports: Don't let your cables sag or rest on sharp metal edges. J-hooks and other purpose-built supports are cheap insurance against long-term cable damage.

- Respect the Bend Radius: Every cable has a minimum bend radius. Forcing a tighter turn than specified can break the internal conductors and kill your signal quality.

A clean, well-documented wiring installation is the single greatest gift you can give to the service tech who comes in five years from now. It turns a frustrating guessing game into a logical process of elimination, saving hours of downtime and labor costs.

Mounting and Grounding Controllers for Reliability

Where and how you mount your control panels is just as important as the wiring itself. These controllers are the brains of the operation, and they need to be protected from the dust, moisture, and vibration of a typical mechanical room.

Always mount panels where they are accessible but out of harm's way. Make sure there’s enough clearance around the panel for a technician to work comfortably and for air to circulate, preventing overheating.

Grounding is another area where you simply cannot cut corners. A solid ground is your primary defense against the electrical noise and transient voltages that can fry sensitive electronics.

- Single-Point Grounding: Establish one clean grounding point for all your BAS panels. This is how you prevent ground loops—a maddening source of interference caused by tiny differences in ground potential.

- Check Ground Resistance: Don't just assume the building ground is good. Verify it. A high-resistance ground connection is almost as useless as no ground at all.

- Bond All Metal Enclosures: Make sure every metal panel door and enclosure is properly bonded to the ground. This provides a safe path for fault currents and protects personnel.

The Power of a Clear Labeling System

Picture this: it's five years down the road, and you have to trace one sensor wire among hundreds of identical gray cables. Without a clear labeling system, it’s a hopeless task. A logical, consistent labeling convention is a hallmark of a professional building automation system installation.

Every cable and termination point needs a unique identifier that ties directly back to your as-built drawings. This creates a roadmap that anyone can follow. It’s a principle that holds true in related fields; our guide on commercial security systems installation also stresses how organized infrastructure makes future service and upgrades vastly simpler.

Even resources for adjacent installations, like a guide to smart home lighting installation, can offer practical tips on wiring and device placement that apply here.

Coordinating with Other Trades On-Site

A BAS project never happens in a vacuum. You'll be sharing the job site with electricians, HVAC techs, plumbers, and a dozen other trades. Good coordination is the only way to stay on schedule and avoid expensive rework.

Get in the habit of attending site meetings and talking to the other foremen. Know their schedules. Identify potential conflicts before they happen. For example, you need to coordinate with the electricians to know exactly when and where power will be available for your panels, and ensure your low-voltage pathways don't cross their high-voltage runs. It’s all about working together to create a fully integrated building.

Bringing Your System to Life with Software

The physical install is done. All the wires are pulled, controllers are mounted neatly on the wall, and everything looks ready to go. But at this point, all you really have is a collection of expensive, dormant hardware. The real magic begins now, during software configuration. This is where we program the intelligence that turns all those isolated devices into a single, cohesive, responsive network.

This is the phase where your building automation system installation truly comes alive. It's where we teach the system how to think, react, and ultimately deliver on the goals we set out in the planning stage. From finding devices on the network to writing the logic that runs an air handler, this step is all about making the software drive performance.

The push for smarter buildings is massive right now. The market hit around .76 billion in 2024 and is on track to reach 1.23 billion by 2025, all thanks to the relentless demand for better energy efficiency and lower operating costs. You can get more details on this explosive growth from The Business Research Company. This just goes to show how critical a well-executed software setup is for actually seeing a return on this investment.

Setting Up Your Central BAS Server

Everything starts with the central BAS server—the brain of the operation. This server hosts the core software that collects data, executes control logic, and gives facility managers their window into the system. Whether it’s a physical server in an IT closet or a virtual machine in the cloud, getting it right is fundamental.

First, you'll install the BAS software from your chosen vendor. This means getting the network settings configured so the server can talk to everything on the BAS network. This is a critical point where you absolutely need to coordinate with the IT department. You'll need their help to get the right permissions, set up firewall rules, and lock in a static IP address for reliable communication.

Once the platform is up and running, it's time for device discovery. Using protocols like BACnet, the server scans the network to find all the controllers, sensors, and actuators you just installed. As each device is discovered, it gets pulled into the system's database, essentially creating a digital twin of your physical hardware.

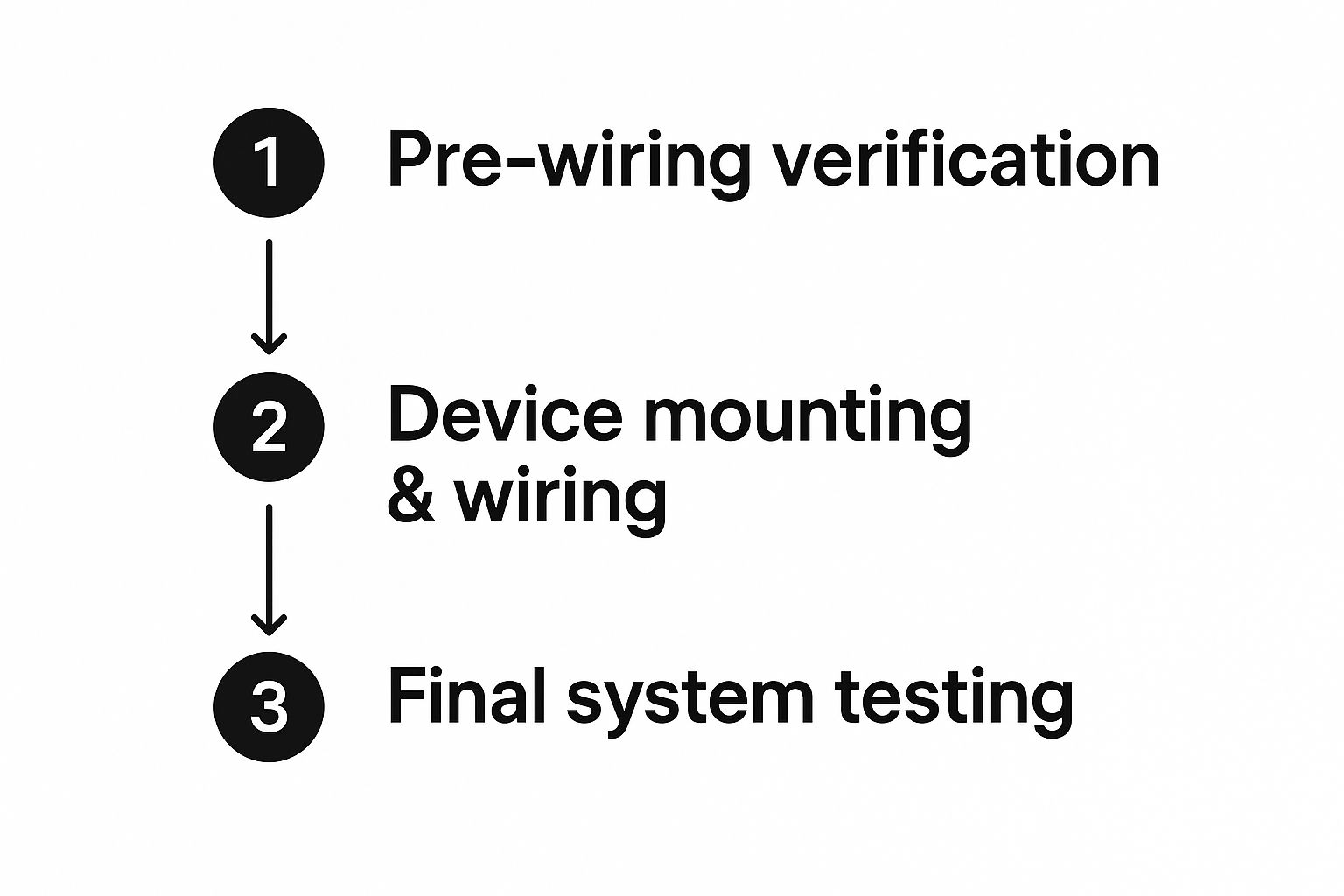

The image below lays out the key stages that lead up to this point, from checking the wiring to final system testing.

As you can see, a methodical physical installation sets a solid foundation, ensuring the software and testing phases go smoothly without hitting major roadblocks.

Programming Sequences of Operation

Now that the server sees all your devices, you can start programming the logic that actually automates the building. We do this by creating "sequences of operation"—basically, sets of rules that tell equipment how to behave based on different inputs. This isn't scary, complex code. Most modern BAS platforms use graphical, block-based programming that’s surprisingly intuitive.

Let's walk through a real-world example: programming a sequence for a rooftop air handling unit (AHU) that serves an office floor.

- Occupancy Scheduling: The first layer of logic is a simple schedule. The AHU runs in "occupied" mode from 7 AM to 6 PM on weekdays. At all other times, it switches to an energy-saving "unoccupied" mode. Simple.

- Temperature Control: During occupied hours, the logic constantly reads the average temperature from sensors on the floor. If the temp climbs above 74°F, it commands the cooling coil valve to open. If it drops below 70°F, it signals the heating coil.

- Ventilation Logic: The system also keeps an eye on CO2 sensors. If CO2 levels creep past 800 parts per million (ppm), the logic tells the outside air damper to open wider, pulling in more fresh air to keep the space from getting stuffy.

- Morning Warm-Up: Here's a more advanced sequence. An hour before the building becomes occupied, the system checks the outside air temperature. If it's below 50°F, the AHU starts early to pre-heat the space, making sure it’s comfortable the moment the first person walks in.

This kind of layered logic transforms a dumb machine into an intelligent unit that’s constantly balancing comfort and efficiency.

Designing User Dashboards and Trends

A powerful BAS is worthless if facility managers can't easily understand and interact with it. The next move is to build intuitive graphical user interfaces (GUIs), or dashboards. A well-designed dashboard gives the team a clear, at-a-glance view of the building's health.

For our AHU example, a good dashboard would include:

- A graphic of the unit showing real-time fan status and damper positions.

- Live readings for temperature, humidity, and CO2 levels.

- Clickable setpoints so a manager can easily tweak the target temperature.

- An alarm summary that flags any operational faults immediately.

The whole point of a dashboard is to turn thousands of data points into actionable information. It should empower facility managers to make smarter, faster decisions—not drown them in raw data.

Beyond live monitoring, setting up historical data trending is an absolute must. By logging key data points over time—like zone temperatures, energy use, and equipment runtime—you build a rich dataset for later analysis. This data is gold for pinpointing efficiency opportunities, troubleshooting nagging issues, and proving the system's ROI.

Integrating Disparate Systems

Finally, a modern building automation system installation rarely works in a vacuum. The real power is unlocked when you integrate other building systems onto a single platform. Using open protocols, you can connect systems that have traditionally been walled off from each other.

- Access Control: You can link the access control system so that when the last person swipes their badge to leave for the day, the BAS automatically puts the lights and HVAC for that zone into unoccupied mode.

- Fire Alarm System: By integrating the fire alarm, the BAS can instantly react in an emergency. It can shut down air handlers to stop smoke from spreading and automatically unlock designated emergency exits.

This level of integration breaks down the silos between systems, creating a building that truly operates as one intelligent entity. It’s the final piece of the puzzle that turns all your carefully installed hardware and software into a genuinely smart building.

Commissioning Your System for Peak Performance

The final stretch of a building automation system installation is easily the most critical, but it's also the phase most often cut short. Commissioning isn't just about flipping a switch to see if the lights turn on. It's a meticulous, exhaustive process of testing every component and sequence to prove the system performs exactly as designed.

Skipping this step is like building a custom race car and never taking it out on the track—you own a powerful asset, but you have no verified proof of what it can actually do. This is where you close the gap between the physical installation and real-world operation, making sure every sensor, wire, and line of code delivers the energy savings and comfort you expect.

Start by Verifying Every Single Connection

Before you can test the system's logic, you have to confirm its nervous system is fully intact. This starts with point-to-point (P2P) checks, a granular but absolutely essential task. The goal is straightforward: verify that every physical device is wired correctly, talking to its controller, and showing up accurately in the software.

Think of a temperature sensor in Room 301. A P2P check confirms that when the physical sensor's value changes, the corresponding data point in the BAS software reflects that change instantly and accurately. For an actuator, like a damper, it means sending a command from your laptop to open it to 50% and then walking over to physically see that it moved to the right position. This methodical approach catches simple installation mistakes—mislabeled wires, wrong device addresses—before they become massive headaches later.

Put the System Through Its Paces with Functional Tests

Once you know all the physical connections are solid, it's time to test the system's brain. Functional performance tests (FPTs) are all about simulating real-world scenarios to ensure your control sequences work flawlessly. This is where you really challenge the system to prove it can "think" on its own.

For instance, to test an air handling unit's economizer logic:

- Simulate a perfect day: Artificially lower the outside air temperature reading in the software to mimic cool, dry conditions.

- Watch the reaction: You should see the BAS command the outside air damper to open, using "free cooling" instead of firing up the energy-hungry mechanical chiller.

- Push the limits: Next, simulate a hot, humid day. The system must respond by closing the outside air damper back to its minimum setting and engaging the chilled water valve.

Running these "what-if" scenarios for every piece of equipment is non-negotiable. It proves the logic will perform efficiently under all possible conditions, not just the ideal ones.

Commissioning is the quality assurance step that guarantees the owner receives the system they paid for. It transforms a collection of components into a fully integrated, performance-optimized building asset ready to deliver on its promises.

Document Everything: The Commissioning Report and As-Builts

The final pillar of a professional commissioning job is the paperwork. A detailed commissioning report is the official record proving the project's success. It should contain all the P2P checklists, the results from every functional test, and a log of any issues found and how they were fixed. This report is your proof of performance.

Just as important are the as-built drawings. These aren't the initial design plans; they're the updated versions that show every single change made during the installation. For a technician doing maintenance five years from now, these drawings are an indispensable roadmap showing exactly how the system was actually installed.

The BAS market is growing fast. In the United States alone, it was valued at an estimated $17.5 billion in 2022 and is projected to hit $30.98 billion by 2030. This boom is fueled by stricter energy codes that require advanced building controls, making thorough commissioning more vital than ever. You can see a full market breakdown from the analysts at Future Market Insights.

To help organize this crucial phase, a checklist is indispensable. Here’s a look at some of the core verification tasks you'll be running.

BAS Commissioning Checklist

| Test Category | Verification Task Example | Expected Outcome |

|---|---|---|

| Physical Installation | Confirm all sensors and actuators are installed in the correct location per as-built drawings. | All devices are physically present, properly mounted, and accessible for future service. |

| Point-to-Point (P2P) | Send a 75% open command to a VAV box damper; physically verify its position. | The damper actuator moves to the commanded position and reports the correct feedback value to the BAS. |

| Control Sequences | Simulate a CO2 reading above 1,000 ppm in a conference room. | The AHU's outside air damper modulates open to increase ventilation until the CO2 setpoint is met. |

| Alarms & Notifications | Manually disconnect a critical temperature sensor. | An alarm is generated in the BAS within 60 seconds and an email/SMS notification is sent to the correct staff. |

| Trend Logs | Verify that historical data for room temperature and energy consumption is being logged every 15 minutes. | Data logs are active, populating correctly, and can be exported for analysis. |

This table provides just a snapshot, but it illustrates the level of detail required to ensure the system is truly ready for handover.

A Professional Handover and Training

The project isn't finished until the building's facility management team is fully prepared to take over. This means more than just dropping a binder of documents on their desk; it requires in-depth, hands-on training.

Walk their team through the main graphics, show them how to adjust setpoints, acknowledge alarms, and run basic performance reports. This knowledge transfer is what empowers them to actually use their new smart building effectively from day one. To learn more about how these interconnected systems function, our guide on the Internet of Things in building automation offers some great background.

Finally, make sure a clear plan for ongoing support is in place so the team knows exactly who to call when they need help down the road.

Answering Your Top BAS Installation Questions

When you're diving into a building automation project, a lot of questions pop up. It’s only natural. Having been in the field for years, I've heard just about all of them. Let's tackle some of the most common ones I hear from project leads and facility managers.

One of the first questions is almost always, "Can we even put a BAS in our old building?" The answer is a resounding yes. Retrofitting older buildings is a huge part of what we do. It just means the initial site survey needs to be extra thorough to figure out how a new system will play nice with the existing mechanical and electrical setups. Thankfully, modern wireless BAS tech has been a game-changer here, making these installs far less disruptive than tearing open walls for new wires.

Then comes the forward-thinking question: "What happens if our needs change in five years?" This is a smart thing to ask, and it highlights why sticking to open protocols like BACnet is so important. When your system is built on an open standard, you aren't stuck with one manufacturer for life. You can add new devices or swap out old ones from any vendor down the road, giving you the flexibility to adapt as your building evolves.

How Long Does Installation Take?

There's no single answer to this one—the timeline for a BAS installation can be anything from a few weeks to several months. It all boils down to the project's size and complexity.

A simple setup in a small office might be quick, but a full-blown integration across a high-rise is a different beast entirely.

A few key things will dictate your schedule:

- Building Size: It’s simple math. More square footage means more wiring, more devices to mount, and a longer commissioning phase.

- System Complexity: A project that just focuses on HVAC controls will move a lot faster than one that ties together HVAC, lighting, access control, and security systems.

- Coordination with Trades: Your timeline is completely dependent on how well you can sync up with the electricians, mechanical contractors, and other teams on site. This is often the biggest variable.

If there's one piece of advice I can give, it's this: A detailed project plan with clear milestones, agreed upon by everyone upfront, is your best defense against delays and scope creep.

Finally, people always want to know about the upkeep. While a modern BAS is built to be pretty self-sufficient, it's not a "set it and forget it" solution. Think of it like a car—it needs regular tune-ups to perform its best. This usually means routine software updates, calibrating sensors to keep them accurate, and double-checking control sequences to ensure you're still getting those energy savings you were promised.

At Clouddle Inc, we specialize in designing and installing the robust network infrastructure that powers modern building automation systems. Learn how our integrated solutions can support your next project.