Before you even think about plugging in a fancy tester, the first and most fundamental step is a simple visual inspection. Seriously. I can't tell you how many times I've seen people chase complex network ghosts for hours, only to find the problem was a cable crushed under a desk leg. A quick once-over can save you a world of hurt.

Start with a Good Old-Fashioned Visual Inspection

Your eyes are your best first-line tool. A surprising number of network failures, from flaky connections to a dead link, are caused by obvious physical damage. Getting into the habit of doing this check first will save you immense time and keep you from diving down unnecessary rabbit holes.

Think of it as a quick pre-flight check. You’re looking for any red flags that point to a physical problem before you start blaming software or hardware.

Check the Cable Jacket from End to End

If you can, run your hand along the entire length of the cable. You're feeling for anything that isn't smooth and uniform.

- Cuts and Abrasions: Look for any deep nicks or spots where the outer plastic jacket is worn away, exposing the fragile twisted pairs inside. This is especially common in high-traffic areas.

- Kinks and Sharp Bends: An Ethernet cable that’s been bent like a paperclip can have damaged internal wiring, even if the jacket looks fine from the outside. These sharp bends are silent killers of network performance.

- Crushed Sections: Pay close attention to spots where the cable might have been pinched by a door, rolled over by an office chair, or caught under heavy equipment. A flattened cable is a huge red flag.

If you find any of these issues, don't try to patch it up with electrical tape. Just replace the cable. It's the only way to guarantee a reliable connection.

Examine the RJ45 Connectors Closely

The little plastic plug at each end—the RJ45 connector—is a notorious point of failure. A bad termination here can cause all sorts of intermittent, frustrating problems.

Get a good look at the clear plastic housing. Are the wires pushed all the way to the end? Do you see shiny copper pins making solid contact? Also, check that the little plastic locking tab isn't snapped off. A broken tab is the number one cause of a cable that works one minute and fails the next because it's not seated securely in the port.

One of the most common mistakes I see, especially with homemade cables, is too much untwisted wire inside the connector. That untwisted section acts like a tiny antenna, picking up interference from nearby power cords and creating crosstalk, which absolutely tanks your network speed.

Choosing the Right Tool for the Job

While a visual check is powerful, some faults are invisible. That's when you need to break out the hardware. But not all cable testers are created equal, and bringing the wrong tool to the fight is just a waste of time and money.

Here's a quick rundown of what you'll find out there.

Choosing Your Network Cable Testing Tool

| Tester Type | Primary Function | Best Use Case | Typical Cost |

|---|---|---|---|

| Continuity/Wiremapper | Checks for basic electrical connections and proper wire mapping (e.g., shorts, opens). | Home networking, small office troubleshooting, and verifying new cable terminations. | $10 – $50 |

| Qualifier | Verifies if a cable can support specific network speeds (e.g., 1 Gbps, 10 Gbps). | Diagnosing if existing cabling can handle a network speed upgrade without replacement. | $500 – $2,000 |

| Certifier | Performs extensive tests against industry standards (TIA/ISO) for metrics like crosstalk and return loss. | Professional installations, data centers, and situations requiring warranty validation. | $2,000 – $15,000+ |

For most people troubleshooting a home network or a small office, a basic continuity tester is all you'll ever need. It quickly answers the most important question: "Is this cable wired correctly from end to end?"

Qualifiers and certifiers are in a different league. They're the specialized gear for pros who need to guarantee that a cable installation meets strict performance standards for things like a 10 Gbps network upgrade or a new data center build-out.

Performing Basic Continuity and Wiremap Tests

Once you’ve given a cable a good visual once-over, it's time to see what’s happening on the inside. This is where a basic network cable tester comes in—an indispensable tool for anyone working with network cabling. These affordable gadgets answer two critical questions almost instantly: is there a complete electrical path (continuity), and are the wires hooked up in the right order (wiremap)?

Think of it as the first line of defense against those maddening, invisible problems. A quick pass/fail from one of these testers can save you from hours of chasing software ghosts or misconfigured devices when the real culprit is just a bad wire.

What Continuity and Wiremap Faults Actually Mean

Let's break down what the tester is looking for. At its most basic, the continuity test checks that each of the eight tiny wires inside the cable makes an unbroken connection from one end to the other. If even one wire is severed, you have what's called an open fault. Simple as that.

The wiremap test goes a step further. It verifies that pin 1 on one connector correctly maps to pin 1 on the other, pin 2 to pin 2, and so on. A failure here points to a mistake during termination, which can cause all sorts of bizarre network behavior that’s a nightmare to diagnose.

Common wiremap faults you’ll run into include:

- Shorts: Two or more wires are making contact, causing signals to bleed into each other.

- Crossed Pairs: An entire wire pair (like orange/white-orange) is swapped with another (like green/white-green).

- Reversed Pairs: The two wires within a single pair are flipped (pin 1 goes to pin 2, and pin 2 goes to pin 1).

- Split Pairs: This one is the trickiest. Wires from two different pairs get mixed up. A cheap tester might even show continuity, but the cable will fail spectacularly under real network load because of massive signal interference (crosstalk).

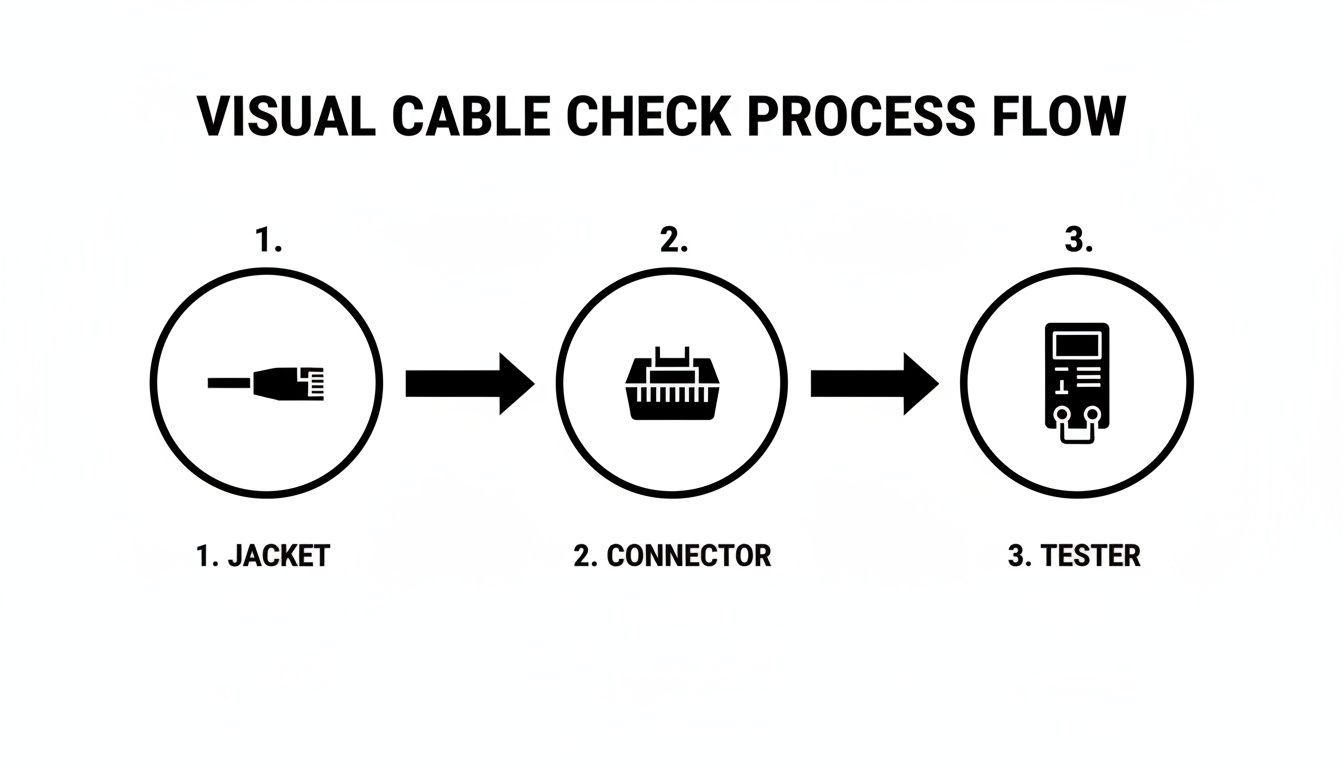

This workflow—checking the jacket, then the connector, then the tester—is a tried-and-true method for isolating physical-layer problems efficiently.

Starting with the most obvious (the outer jacket) and moving to the most detailed (the internal wiring) ensures you don't miss anything.

How to Use a Basic Network Tester

Using one of these testers couldn't be easier. They come in two pieces: the main unit and a remote terminator. The whole process takes less than a minute.

You just plug one end of your cable into the main tester and the other end into the remote terminator—which might be in another room entirely. Switch the tester on, and it will automatically send a signal down each of the eight wires.

The results are typically displayed on a series of eight LED lights. If everything is perfect, you'll see the lights on both the main unit and the remote blink in sequence from 1 through 8. That's a pass.

Any other pattern means trouble. Light #3 not lighting up? You've got an open on that wire. Lights #4 and #5 flashing together? They're probably shorted.

My Two Cents: If you're terminating your own cables, test every single one before you put it into service. I can't tell you how many network "emergencies" I've seen that trace back to a hastily made patch cord. That ten-second test will save you from a multi-hour headache down the road.

A Real-World Scenario: The 100 Mbps Bottleneck

Here's a classic situation where a wiremap test is the hero. You’ve just installed a brand-new gigabit switch and your PC has a gigabit NIC, but for some reason, your connection is capped at a sluggish 100 Mbps. What’s going on?

Gigabit Ethernet (1000 Mbps) needs all four pairs of wires—all eight conductors—to be working perfectly. But the older 100 Mbps standard only uses two pairs (wires 1, 2, 3, and 6).

If there's a break on any of the wires that Gigabit needs but 100 Mbps doesn't (like 4, 5, 7, or 8), your network devices are smart enough to detect it. They can't establish a gigabit link, so they automatically fall back to the next best thing: 100 Mbps.

The cable "works," but you're leaving 90% of your performance on the table because of one bad wire. This is a perfect example of why knowing the difference between Cat 5 and Cat 6 cable wiring standards is so important for troubleshooting. Without a tester, you'd never see it.

Professional Cable Certification: The Gold Standard

When you’re dealing with more than just a home office or a small business setup, a simple continuity test won't fly. For critical infrastructure, data centers, or demanding applications like 10GBASE-T, performance isn't just a goal—it's the entire point. This is where professional cable certification enters the picture.

Think of certification as less of a pass/fail test and more of a full-blown scientific analysis. It rigorously measures a cable's performance against the tough standards set by industry bodies like the TIA (Telecommunications Industry Association) and ISO. It's the definitive proof that your cabling can handle the heavy data loads of a modern network without even breaking a sweat.

What the Certification Report Actually Tells You

An advanced cable certifier, like the kind you'll see from industry staples like Fluke Networks, doesn't just check for a connection. It blasts the cable with high-frequency signals to measure a whole suite of performance parameters. The full report can look a bit intimidating, but a few key metrics really tell most of the story.

- Near-End Crosstalk (NEXT): Imagine trying to whisper to someone in a crowded, noisy room. NEXT is the "noise" that leaks from one pair of wires onto an adjacent pair at the same end of the cable. Too much of this crosstalk corrupts the data signal, causing errors and forcing re-transmissions that absolutely kill your network speed.

- Return Loss: This is a measure of the signal that gets reflected back to the source because of imperfections in the cable or connectors. High return loss is like a bad echo on a phone call—it weakens the original signal and can make it completely unreadable by the time it gets to the other end.

- Attenuation: In the simplest terms, attenuation is just the loss of signal strength as it travels down the cable. Every cable has some, but a certifier makes sure it stays within the acceptable limits for the cable's category and length. If the signal arrives too weak, it's useless.

Getting these factors right during the design phase is half the battle. For a closer look at how these elements fit together, our guide on what is structured cabling offers some great foundational knowledge. A well-designed system is built from the ground up to minimize these negative effects.

The Real Reason Certification Matters: Proof

So, why go through all this trouble? Because a certification report is the ultimate proof of a quality installation. For a cabling contractor, it's the document that proves their work is up to spec, which means a smooth project sign-off and a happy client.

For the building owner or IT manager, these reports are pure gold. They create a performance baseline for any future troubleshooting and are often mandatory to validate the multi-decade warranties offered by cabling manufacturers. Without that certified report, your 25-year performance warranty might not be worth the paper it's printed on.

Here’s a snapshot of the kind of detailed diagnostics you get from a professional certifier.

The screen gives you a full breakdown, showing a clear pass or fail for crucial metrics like NEXT and Return Loss for every single wire pair. It's this level of detail that ensures every inch of the cable meets strict TIA standards.

This rigorous testing is precisely why certification became the industry benchmark. After the TIA-568-B standard was updated in 2001 to formalize tests for Cat5e and Cat6, the quality of network installations shot up. Pass rates for certified projects jumped from around 65% in the early 2000s to over 95% by 2020. This process is vital, especially when you consider that uncertified cabling is blamed for up to 40% of network failures in enterprise environments.

A true professional installer doesn't just pull cable; they deliver a certified, warrantied system. That certification report is their promise that the physical foundation of your network is rock-solid and ready for whatever you plan to throw at it.

When Is Certification an Absolute Must?

While it’s definitely overkill for patching in a new printer, certification is non-negotiable in several key situations.

- New Construction: Any new commercial building or data center build-out requires every single cable drop to be certified. It’s essential for meeting building codes and performance specifications.

- High-Speed Network Upgrades: Moving your infrastructure to support 10 Gbps or faster speeds? Certifying the existing cable plant is the only way to know for sure if it can handle the extra demand.

- Manufacturer Warranties: To activate those 20 or 25-year system warranties from big names like CommScope or Panduit, you have to provide complete certification reports for the entire installation. No report, no warranty.

- Mission-Critical Environments: In places like hospitals, financial trading floors, or 911 dispatch centers, network downtime isn't an option. Certification provides an indispensable layer of reliability and peace of mind.

Ultimately, certifying your network cabling is an investment in stability. It removes the physical layer as a potential point of failure, allowing you to build and manage your network with the confidence that its foundation is verifiably sound.

Pinpointing Faults with Time Domain Reflectometry

Knowing a cable has failed is one thing. Knowing exactly where it failed is a total game-changer.

Imagine you've got a cable running 200 feet through walls and ceilings. A basic continuity test might tell you there's an open circuit, but it won't say if the break is five feet from the patch panel or 150 feet away, hidden above a hard-lid ceiling. This is where you stop guessing and start getting precise.

Advanced network testers use a powerful technology called Time Domain Reflectometry (TDR) to solve this exact problem. Think of it like radar for your network cabling—it lets you pinpoint the physical location of a fault with incredible accuracy, often down to a few inches.

This tech has been a diagnostics workhorse since the 1960s. For Ethernet cables, it sends a low-voltage pulse down the wire and can locate faults within a meter over a 100-meter run. A 2018 study even found that TDR testing reduced cable fault diagnosis time by 85% compared to hunting for the problem manually, which saves data centers a fortune in downtime. You can dig into the specifics of this technology's impact in studies on network data cabling installation.

How TDR Works Its Magic

The idea behind TDR is actually pretty straightforward. The tester sends a small electrical signal down a copper wire pair. As this signal travels, it's looking for a consistent impedance, which you can think of as the "road condition" for the signal. When the cable is perfect, the signal zips along to the end without a problem.

But, if that signal hits an imperfection—a change in impedance—some of that signal's energy bounces back to the tester, just like an echo.

What causes these reflections? Usually one of these culprits:

- An open circuit: A complete break in the wire. This creates a huge impedance change and reflects a strong, positive echo.

- A short circuit: When two wires touch, the impedance plummets, sending a negative echo back to the tester.

- Sharp bends or kinks: Even a nasty bend can slightly change the cable's internal geometry and impedance, creating a small blip on the TDR's radar.

- Poor terminations: A wire that isn't seated properly in an RJ45 connector creates a small but very detectable impedance mismatch right at the end of the line.

The tester has a highly accurate internal clock that measures the exact time it takes for this echo to return. Because it knows the signal's speed (its Nominal Velocity of Propagation, or NVP), the device does some quick math: (Time × Speed) / 2 = Distance. This simple formula is how it can confidently tell you the fault is 47.3 feet down the line.

Practical Scenarios Where TDR Shines

The real value of TDR snaps into focus when you're faced with a real-world problem that would otherwise be a complete nightmare. It turns a frustrating hunt-and-peck troubleshooting session into a surgical strike.

The first time I used a tester with TDR, we were trying to find a single bad cable in a bundle of 50 we'd just pulled for a new office. The tester lit up with a "short" at exactly 78 feet. We walked the line, found a drywall screw piercing the conduit right at that spot, and sure enough, it had gone straight through our cable. What could have been a full day of re-pulling wires was fixed in 30 minutes.

Here are a few other times TDR is an absolute lifesaver:

- Construction Damage: Finding where a flooring staple or a picture-hanging nail has nicked a cable hidden inside a wall.

- Hidden Splices: Detecting a dodgy, unauthorized splice that a previous technician hid in the ceiling space.

- Connector Issues: Confirming the problem isn't somewhere in the 150-foot run, but is actually just inches from the end because of a bad punch-down at the wall jack.

- Water Damage: Pinpointing the exact spot where water has seeped into a cable jacket and is causing a short between pairs.

By giving you a precise distance to the fault, TDR lets you make a targeted repair instead of jumping straight to the costly and disruptive job of replacing an entire cable run. For anyone serious about professional and efficient network maintenance, it's an absolutely essential tool.

Validating Network Performance and PoE Delivery

A cable can pass every electrical test on the bench, but the real proof is how it performs in a live network. This is where the rubber meets the road. We need to confirm that its physical integrity actually translates into the data speeds and power delivery we expect. It's the final, crucial step before you can call the job done.

The simplest place to start is with the link lights on your switch and network card. Believe it or not, these little LEDs are your first line of defense, giving you a quick, at-a-glance status check without firing up any software.

This simple visual check moves you beyond just confirming continuity; it tells you that two devices are actively talking and have agreed on a connection speed.

Interpreting Link and Activity Lights

Once you plug in the cable, the link lights at both ends should light up, typically solid green or amber. A solid light is a good sign—it means a physical link is established. The color often gives you a hint about the speed. For instance, amber might signal a 100 Mbps connection, while green usually means you've hit the full 1 Gbps link speed.

A blinking light, on the other hand, indicates data activity. Seeing it flicker is great, as it means data packets are actually flowing across the wire. If you get a solid link light but see no activity at all, the problem might not be the cable but a configuration issue further up the network stack.

Checking Power Over Ethernet Delivery

More and more devices—like security cameras, VoIP phones, and access points—are powered directly over their network connection. This makes verifying Power over Ethernet (PoE) a critical part of the testing process. These devices need a stable supply of both data and power from that one cable.

For this, you'll want a specialized PoE tester. You plug it in between the PoE switch and the end device to measure the exact voltage and wattage being delivered. This is much more than a simple voltage check; these tools apply a load to mimic a real device drawing power.

This load testing is non-negotiable. I've seen cables with shoddy terminations or that are just a bit too long show the correct voltage with no load, only to fail the moment a device tries to draw its required wattage. If you want a deeper dive into how this technology works, our guide on what is a PoE security camera has you covered.

Measuring Real-World Data Throughput

Link lights confirm a connection exists, but they say nothing about its quality. To get the full picture, you need to measure the actual data throughput. A tool like iperf is perfect for this—think of it as a speedometer for your network connection.

You run iperf in server mode on one computer and client mode on another, which sends a stream of data through the cable and measures the real-world bandwidth. This kind of stress test can uncover problems that a simple continuity check would never catch, like interference that only rears its ugly head under a heavy load. A cable that passes a wiremap test but only gives you 500 Mbps in iperf has a performance issue that needs a closer look.

While we're talking about copper, it's worth noting that fiber optic systems require the same level of rigorous testing. For fiber, technicians verify that optical loss is under 0.3 dB/km for single-mode fiber, which is absolutely essential for modern 400G networks. They use specialized power meters that measure signals with a precision down to 0.01 dB, a standard found in 95% of certified Tier 1 provider networks.

After confirming your cables are installed and tested correctly, the next step is maintaining that performance. To learn more about broader network optimization, check out these tips to improve internet speed.

Answering Your Top Cable Testing Questions

Even with the best guide, you'll always run into questions out in the field. Let's break down some of the most common head-scratchers that trip up both seasoned techs and DIYers when testing network cables.

Can I Test a Cable That's Plugged In and Live?

The short answer is no, you really shouldn't. While you technically could plug a basic tester into a live port, it’s a terrible idea. Sending even a small, unexpected voltage from a continuity tester back into a network switch can easily fry the port on the switch, damage your tester, or both.

For any kind of physical wiremap or continuity test, you need to always disconnect the cable from all network equipment at both ends. It’s the only way to get an accurate reading and keep your gear safe.

The only time you should test a "live" cable is when you're specifically running performance validation checks. Tools like iperf or a PoE tester are designed to measure how the cable behaves under real-world network load, but these are a different class of test altogether.

A simple rule of thumb will save you a lot of grief and money: if the tester isn't made for live network analysis, unplug the cable first. That one moment of caution can prevent a very costly mistake.

My Cable Passed a Continuity Test, So Why Is It So Slow?

This is easily one of the most frustrating problems you'll encounter. Your basic tester gives you the all-clear—all eight wires are connected end-to-end—but the connection is slow or drops packets constantly. This almost always means there's a problem that a simple continuity checker just can't see.

Here are the usual culprits I run into:

- Split Pairs: This is a classic wiring mistake. The wires are connected one-to-one, but pairs are mixed (e.g., a wire from the orange pair is grouped with one from the green pair). Your basic tester sees a connection and passes it, but this incorrect pairing creates massive crosstalk and absolutely tanks your performance.

- Excessive Untwisting at the Jack: When terminating an RJ45 connector, if you untwist the pairs for more than half an inch, the wires lose their noise-canceling properties. They essentially become tiny antennas that pick up interference, leading to data errors.

- Running Near Interference: Is the cable strapped to a power conduit? Is it running right next to a bank of fluorescent lights? High-voltage lines and other sources of electromagnetic interference (EMI) can induce noise that corrupts the data signal.

- Stretching the Distance Limit: Ethernet has a hard limit of 100 meters (328 feet). You might get a link light on a longer run, but the signal will be so degraded (a problem called attenuation) that you'll see a massive performance drop and constant errors.

To find these kinds of issues, you’ll need to step up from a simple continuity tester to a cable qualifier or, for the most thorough analysis, a full-blown certifier.

Should I Bother Testing Pre-Made Patch Cords?

Yes. 100% yes. While factory-made cables are usually much more reliable than ones terminated by hand, they are not infallible. I've pulled brand-new patch cords right out of the bag that were dead on arrival with an open circuit or a mis-wired connector. It happens more often than you'd think.

Making a quick test part of your workflow is a non-negotiable best practice. Whether it’s a 300-foot cable you just crimped or a 3-foot patch cord you just unboxed, test it. A ten-second check with a tester can save you hours of pulling your hair out later, trying to diagnose a "phantom" network issue that was just a bad cable all along.

Navigating the complexities of network infrastructure requires more than just good cables; it demands expert planning and support. At Clouddle Inc, we provide managed technology solutions that ensure your network's foundation is solid and your systems run flawlessly. From structured cabling to integrated security and cloud services, we deliver the reliability your business needs. Discover our comprehensive IT solutions and build a network you can count on.