Your network infrastructure is only as strong as the cabling that supports it. A poorly planned structured cabling design creates bottlenecks, increases maintenance costs, and leaves your organization vulnerable to failures.

At Clouddle, we’ve seen firsthand how the right foundation prevents these problems. This guide walks you through planning, designing, and implementing cabling infrastructure that scales with your business.

Planning Your Structured Cabling Foundation

What You Must Measure Before Designing Your System

Start by documenting what you actually have today, not what you think you have. Most organizations have incomplete or inaccurate infrastructure inventories. Walk through your building with a notebook and physically count active ports, identify where equipment sits, and measure distances from your main distribution frame to end points. ANSI/TIA-568 specifies that horizontal cabling runs cannot exceed 90 meters, with total installed length including patch cords capped at 100 meters, so accurate measurements matter immediately. Sketch your floor plans and mark cable routes, conduit locations, and potential obstacles like HVAC systems or structural columns. This groundwork prevents expensive mistakes during installation.

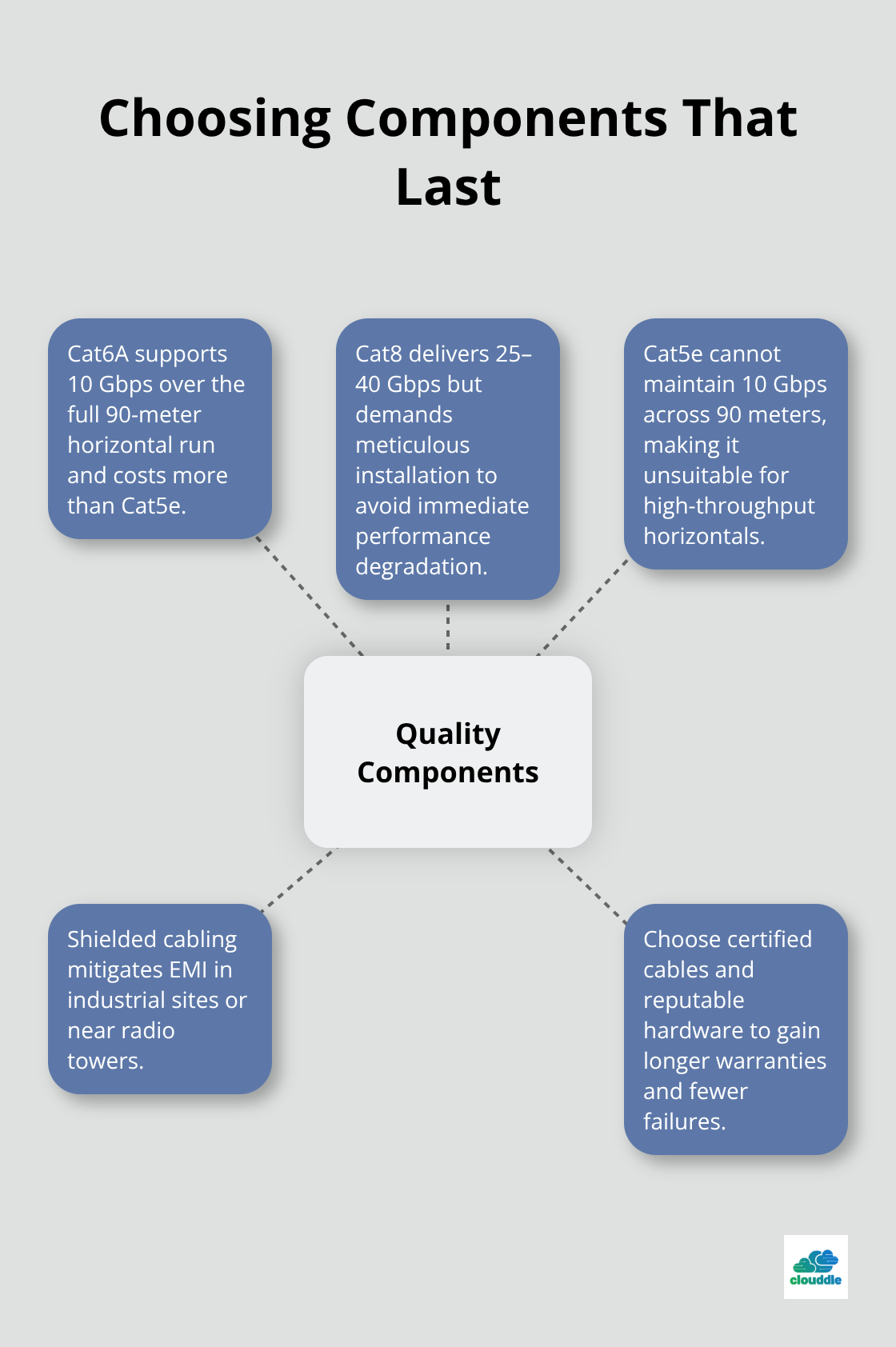

Next, interview your department heads about actual bandwidth consumption. Ask them what they run today-video conferencing, large file transfers, cloud applications-and what they plan to add within the next three to five years. Most businesses underestimate growth; plan for at least double your current needs. If your organization processes video content, handles large databases, or relies on real-time collaboration tools, expect exponential bandwidth demands. Cat6A cabling supports 10 Gbps reliably, while Cat8 reaches 25 to 40 Gbps, so knowing your trajectory helps you avoid premature obsolescence.

Document which areas need the most density-data centers, conference rooms, and open-plan offices consume more ports than traditional offices. A 24-port patch panel works well for small deployments, but high-density environments need modular systems with room to grow.

Align Your Design with Standards From Day One

The ANSI/TIA-568-E standard (2020 revision) provides the backbone for your planning because it covers copper categories, fiber optics, and installation practices that ensure interoperability across vendors. This matters because components from different manufacturers only work together reliably when they follow the same standard. Federal contracts require T568A termination patterns, and most enterprise environments demand compliance too. Your design should specify T568A for all horizontal cabling, which reduces confusion during installation and troubleshooting.

Plan your infrastructure around a hierarchical topology: main cross-connects feed intermediate cross-connects, which feed horizontal cross-connects in a star pattern. This structure simplifies maintenance, supports future expansion, and aligns with how modern networks actually operate. If you build a data center or large facility, TIA maintains dedicated guidelines for those environments, so reference them early rather than retrofitting later. International alignment also matters if your organization operates across borders-ISO/IEC 11801 parallels ANSI/TIA-568, so designs that follow American standards typically work globally.

Map Your Physical Constraints and Growth Areas

Identify conduit and cable tray routes before you finalize your design. Existing buildings often have limited pathways, forcing compromises between ideal routing and practical installation. Measure ceiling heights, check for asbestos or hazardous materials, and confirm whether you can run new conduit or must reuse existing infrastructure. High-EMI environments like industrial facilities or buildings near radio towers need shielded cables and proper grounding to minimize interference-plan for that cost upfront rather than troubleshooting noise problems later.

Reserve 30 percent extra capacity in your conduit and cable trays because future upgrades always consume more space than you expect. Identify hot spots where you need higher-density connections and plan consolidation points if your layout includes open-plan offices where multiple desks share one wall.

These decisions shape your component choices and installation sequence, so getting them right during planning saves thousands in rework costs. With your physical constraints mapped and growth areas identified, you can now move forward to selecting the right components and materials that will support your infrastructure for years to come.

Design Principles for Long-Term Reliability

Follow Standards to Prevent Failure

Standards exist for one reason: to prevent failure. ANSI/TIA-568-C.0 defines the overall premises infrastructure for copper and fiber cabling. When you deviate from standards, you lose that interoperability guarantee. Federal contracts mandate T568A termination, and enterprise environments demand it too-not because of bureaucracy, but because consistency eliminates troubleshooting nightmares. Your design should specify T568A for all horizontal cabling without exception.

The hierarchical topology outlined in ANSI/TIA-568 works because it mirrors how modern networks actually operate. A main cross-connect is connected via a star pattern to intermediate cross-connects, which feed horizontal cross-connects. This structure scales predictably and simplifies maintenance. If you build a data center, TIA publishes dedicated guidelines for those environments; reference them during your initial planning phase, not after construction begins. International deployments require alignment with ISO/IEC 11801, which parallels American standards closely, so designs following ANSI/TIA-568 typically work globally without redesign. Compliance isn’t optional-it’s the foundation that prevents expensive rework and vendor lock-in.

Select Quality Components That Survive Years of Use

Component quality directly determines infrastructure lifespan. Cat6A cabling costs roughly 20 to 30 percent more than Cat5e but supports 10 Gbps reliably over the full 90-meter horizontal run, while Cat5e fails at that distance and speed. Cat8 reaches 25 to 40 Gbps but requires meticulous installation; improper termination or excessive pulling tension degrades performance immediately.

Purchase cables from manufacturers with documented compliance certifications, not bargain suppliers offering no warranty.

Shielded cables cost more upfront but eliminate EMI problems in industrial facilities or buildings near radio towers; unshielded cables in those environments create persistent noise and intermittent failures. Patch panels, connectors, and termination hardware from reputable vendors carry longer warranties and fail less frequently than commodity alternatives. High-density patch panels with modular keystone slots provide flexibility for future technology changes without rewiring entire runs.

Build Redundancy Into Your Backbone

Plan for redundancy in your backbone by installing separate fiber paths between main and intermediate cross-connects. If one path fails, traffic routes through the alternate without disruption. Dual power supplies in active equipment and separate UPS systems for different zones prevent single points of failure. These investments cost more initially but eliminate the catastrophic downtime that forces emergency repairs and damages your organization’s reputation.

Test and Document Everything Before Handoff

Test every cable run with continuity testers, wire mapping tools, and signal loss measurements before you declare the installation complete. Field testing catches termination errors immediately rather than after equipment deployment. Document everything-cable runs, termination patterns, equipment locations, and test results-in spreadsheets or cable management software so future technicians can troubleshoot efficiently without guessing. This documentation becomes invaluable when you add new equipment, troubleshoot intermittent problems, or hand off infrastructure to a new team. With your components selected and your redundancy strategy in place, you now face the practical challenge of actually installing this infrastructure without disrupting your business operations.

Installation and Optimization Best Practices

Schedule Installation to Protect Operations

Cable installation is where planning meets reality, and most organizations rush this phase to minimize downtime. That’s the wrong priority. A sloppy installation creates technical debt that costs far more to fix later than taking an extra week to do it properly. Start your installation during a planned maintenance window when you can afford outages, not during peak business hours. If your organization runs 24/7, schedule work in phases that isolate non-critical areas first, then migrate systems to the new cabling infrastructure in stages. This approach takes longer but prevents the catastrophic failures that force emergency repairs at triple the normal cost.

Label and Organize Every Cable Before Termination

Label every single cable at both ends before you terminate anything. Use a consistent naming scheme like Floor-Room-Port-Number and apply it to patch panels, wall jacks, and equipment connections. Messy labeling creates troubleshooting nightmares; technicians waste hours tracing cables when documentation is missing.

Implement proper cable management with trays or raceways that keep cables organized and protected from physical damage. Cables pulled taut across sharp edges or crushed under equipment fail prematurely, sometimes months after installation when you’ve already signed off on the project.

Execute Terminations With Precision

Termination quality determines everything. Use the correct tool for your connector type, apply consistent tension, and follow the T568A pattern without exception. Improper terminations cause intermittent failures that appear weeks later and drive technicians crazy because they’re nearly impossible to diagnose. Test every cable run with a continuity tester, wire map tool, and signal loss meter before you connect equipment. Field testing catches errors immediately when they’re cheap to fix.

Document test results in spreadsheets or cable management software alongside your physical installation photos and equipment locations. This documentation prevents rework and enables faster troubleshooting when problems arise.

Migrate Systems in Phases to Eliminate Risk

Plan your installation sequence to minimize disruption: install infrastructure in non-critical areas first, test thoroughly, then migrate systems from old cabling to new cabling in small groups. This phased approach lets you verify that everything works before you touch critical services. If you’re upgrading from Cat5e to Cat6A, don’t try to replace everything at once. Instead, migrate departments one at a time, test each migration thoroughly, and keep your old cabling active as a fallback if unexpected problems emerge. This strategy costs more in labor but eliminates the risk of a catastrophic failure that takes down your entire network during peak hours.

Final Thoughts

Structured cabling design succeeds when you treat planning as seriously as installation. Organizations that avoid costly rework measure twice, follow standards without compromise, and test everything before declaring the project complete. Your infrastructure will outlast three technology cycles if you build it right from the start, but it will fail repeatedly if you cut corners on components, documentation, or installation discipline.

The most common mistakes happen because teams rush through the physical inventory phase and discover mid-installation that their measurements were wrong. They ignore ANSI/TIA-568 standards and create vendor lock-in that makes future upgrades expensive. They use cheap cables that fail within two years, then blame the infrastructure instead of acknowledging the false economy. They terminate cables sloppily and spend months troubleshooting intermittent failures that proper testing would have caught immediately. They fail to document anything, so when problems arise, technicians waste hours tracing cables and guessing at configurations.

Clouddle provides managed IT and data cabling solutions with 24/7 support and flexible contracts to help you design and deploy infrastructure that actually works. Start planning your cabling infrastructure today and build the foundation that enables growth, new services, and minimal downtime for years to come.