Fiber optic cable installation cost varies dramatically based on project scope, location, and technical requirements. Most businesses underestimate the total investment needed for professional installation.

We at Clouddle see companies spend anywhere from $1 to $6 per foot for basic installations, but complex projects can reach $15 per foot or more.

Understanding these cost factors helps you budget accurately and avoid expensive surprises during your network upgrade.

What Drives Your Installation Costs Up

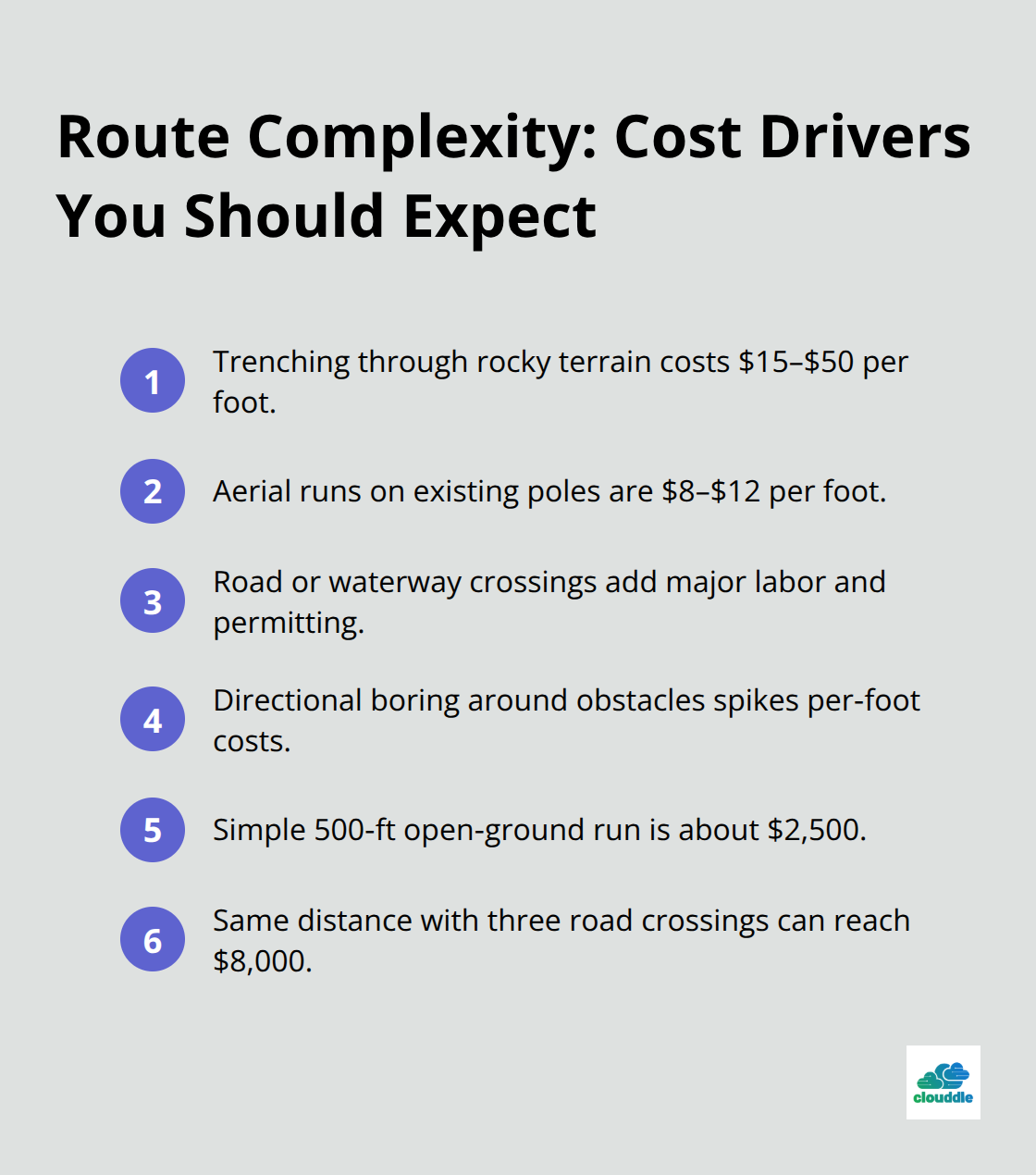

Route Complexity Creates the Biggest Price Impact

Route complexity stands as the single biggest cost driver in fiber installations. Underground trenching through rocky terrain costs $15-50 per linear foot, while aerial installations on existing poles run just $8-12 per foot. Installations that cross roads, waterways, or require directional boring around obstacles create dramatic price differences. A 500-foot run through open ground might cost $2,500, but the same distance that requires three road crossings jumps to $8,000.

Cable Performance Determines Material Investment

Single-mode fiber cables cost $0.09-1.52 per foot and handle long-distance applications perfectly. Multimode OM4 cables run .50-6.00 per foot but work best for shorter connections within buildings. Armored cables add serious protection at $6.00-13.50 per foot in harsh environments. Plenum-rated cables cost 40% more than standard PVC versions but meet strict building code requirements. Higher strand counts (like 432 or 864 fibers) cost significantly more upfront but prevent expensive future upgrades.

Installation Method Controls Labor Expenses

Professional installation rates range from $50-150 per hour based on regional demand and project complexity. Direct burial installations cost -6 per linear foot for simple runs, while complex underground work that requires conduit installation adds per foot. Aerial installations need specialized bucket trucks and certified technicians, which pushes hourly rates higher. Testing and certification fees add $200-500 per project but prevent costly rework later. Permit costs vary from $50-500 based on local regulations and installation scope.

These cost factors work together to create your total project budget, but smart planning can help you reduce operational costs without sacrificing quality.

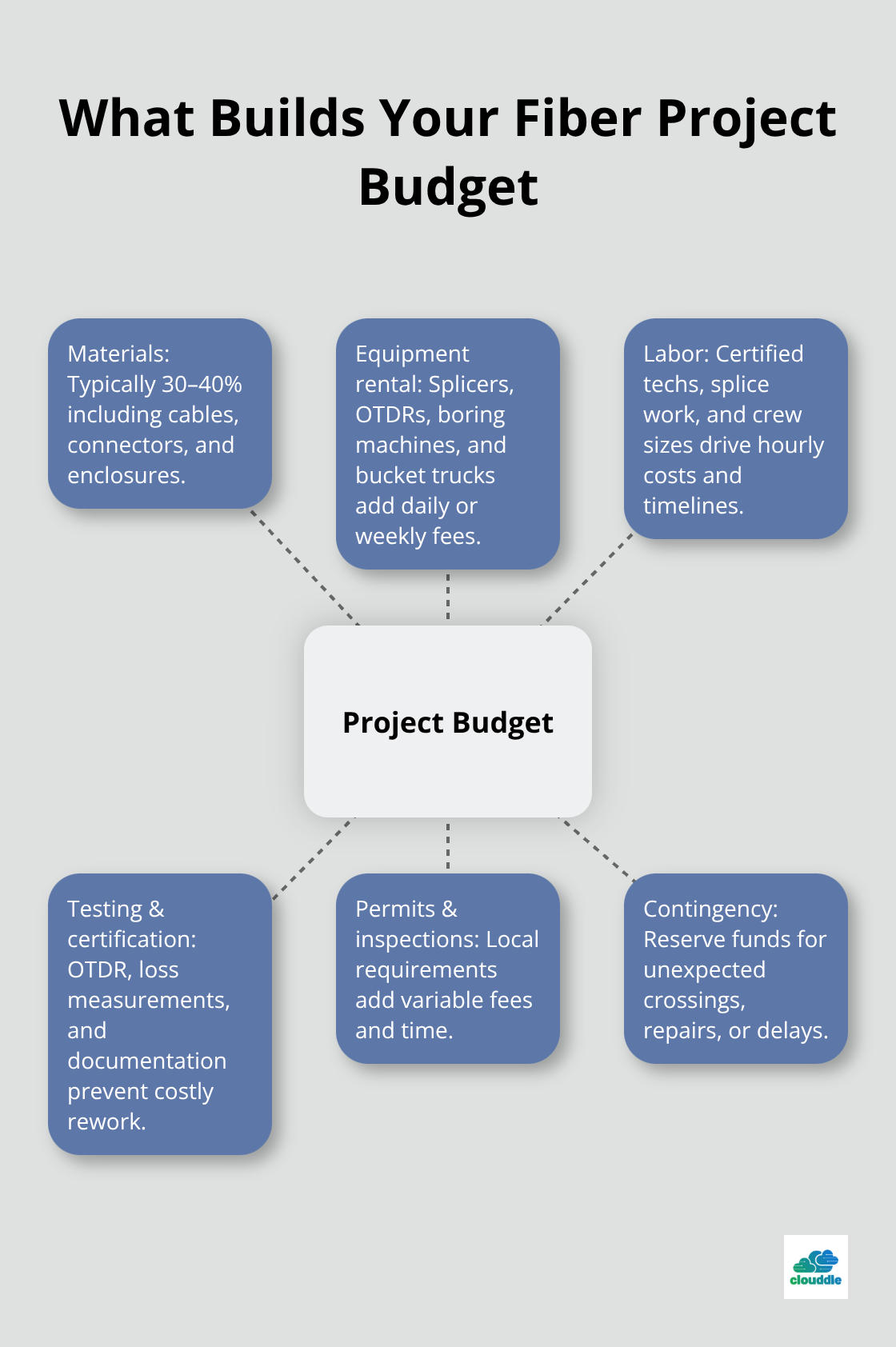

What Makes Up Your Total Project Budget

Material Costs Form Your Foundation

Material costs account for 30-40% of total project expenses, with cables as the primary component. Standard single-mode cables cost $0.09-1.49 per foot, while high-performance OM4 multimode cables reach $6 per foot. Hardware components like patch panels, connectors, and termination boxes add $50-200 per connection point.

Armored cables in industrial environments cost $6-13.50 per foot but prevent expensive damage repairs later. Professional-grade splice enclosures run $300-800 each, while basic junction boxes cost $50-150.

Equipment Rental Adds Daily Expenses

Equipment rental creates significant daily costs that accumulate quickly. Fusion splicers rent for $200-500 daily, while OTDR testing equipment costs $288-350 per week. Specialized boring machines for underground installations command 0-1,200 daily rates. Bucket trucks for aerial work add $400-600 per day (including operator fees). Cable pulling equipment and conduit installation tools typically rent for 0-250 daily, depending on project complexity.

Labor Rates Drive Project Timelines

Professional installation labor commands $75-150 per hour in most markets, with certified fiber technicians earning premium rates. Splice technicians charge $100-200 per splice point, while testing specialists add $50-75 per hour for certification work. Installation crews typically work in teams of 2-3 people, which multiplies hourly costs significantly. Complex underground installations require 8-12 hours per 1,000 feet, while aerial installations complete 1,000 feet in 4-6 hours. Weekend and emergency work carries 50-100% premium rates.

Testing Adds Quality Assurance Value

OTDR testing costs 0-500 per project but identifies problems before they cause network failures. Insertion loss testing adds $25-50 per connection point, while return loss measurements cost $15-30 per termination. Certification documentation fees range from $100-300 per project but satisfy warranty requirements. Post-installation testing typically takes 2-4 hours for standard installations, with complex networks requiring full-day testing sessions at 0-1,200 total cost.

Smart project planning can significantly reduce operational costs through strategic timing and resource optimization.

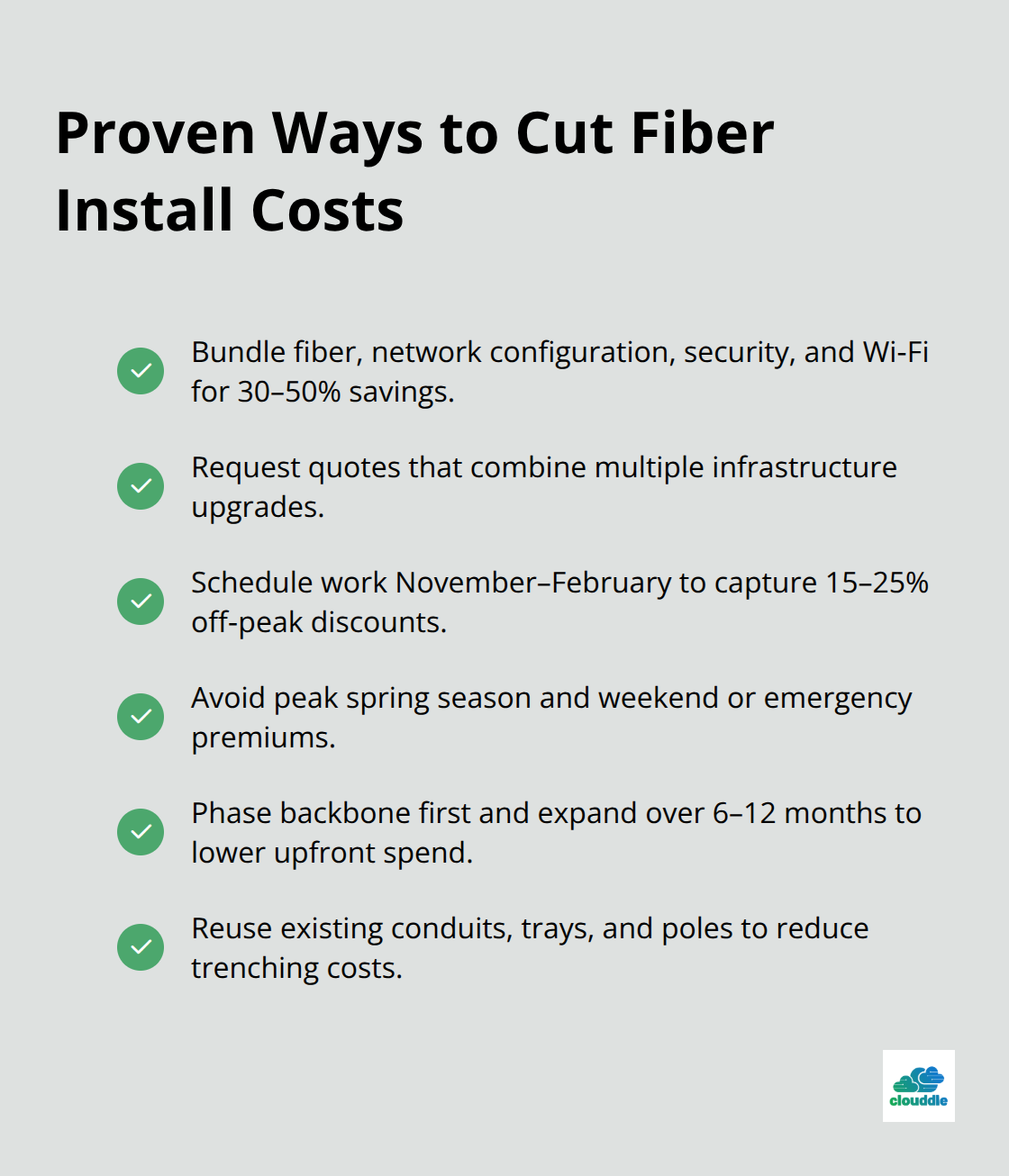

How to Cut Installation Costs in Half

Bundle Services for Maximum Savings

Single-provider bundles deliver 30-50% cost reductions compared to separate installations. Contractors offer significant discounts when you combine fiber installation with network configuration, security system integration, or Wi-Fi deployment. Businesses save $5,000-15,000 on projects over $25,000 when they bundle multiple infrastructure upgrades.

Professional installers prefer larger contracts because they reduce scheduling complexity and equipment mobilization costs. Request quotes for fiber installation alongside planned electrical work, HVAC upgrades, or building renovations to maximize your negotiation power with contractors.

Schedule Projects for Off-Peak Advantages

Winter installations cost less than peak summer projects due to reduced contractor demand and better equipment availability. November through February represents the sweet spot for fiber installations, with many contractors offering 15-25% discounts to maintain steady work during slower months. Avoid installation during spring construction season when demand peaks and prices surge. Schedule installations at least 60 days ahead during off-peak periods to secure better rates and preferred time slots. Mid-week installations typically cost 10-15% less than weekend projects, while you avoid emergency timelines that carry 50-100% premium charges.

Phase Implementation to Spread Costs

Phased installations reduce upfront capital requirements while they maintain project momentum. Start with critical network backbone connections, then expand to secondary areas over 6-12 months as budget allows. This approach cuts initial costs by 40-60% while it provides immediate connectivity benefits. Install conduit and pull boxes during phase one, then add cables during subsequent phases to avoid repeated trenching costs. Many businesses complete phase one for $8,000-12,000, then add phases at $3,000-5,000 each.

Leverage Existing Infrastructure

Existing infrastructure like cable trays, conduits, or pole attachments can reduce installation costs by 30-50% when properly assessed and utilized during the planning phase. Use existing conduits to cut installation costs dramatically (often saving thousands on trenching expenses). Aerial installations on existing poles cost significantly less than new pole construction or underground alternatives.

Final Thoughts

Fiber optic cable installation cost varies based on route complexity, cable specifications, and labor rates across different markets. Underground installations cost -50 per foot, while aerial options run -12 per foot with materials accounting for 30-40% of total budgets. Professional contractors charge $75-150 per hour but prevent expensive mistakes through proper assessment and planning.

Smart project management reduces costs by 30-50% through strategic timing and resource optimization techniques. Experienced installers identify opportunities to use existing infrastructure and spot potential obstacles before they become expensive problems. Winter installations typically cost 15-25% less than peak season projects (with contractors offering better rates during slower months).

Quality fiber installations deliver 99.9% uptime and support speeds over 1,000 Mbps for decades without major maintenance requirements. The initial investment pays returns within 2-3 years through increased productivity and reduced operational expenses. Clouddle provides comprehensive networking solutions that eliminate upfront costs while offering 24/7 support and flexible contracts.