Most IT departments treat system management as an afterthought. They react to failures instead of planning for them, which costs time and money.

Life cycle management in IT is the antidote. It’s a structured approach that guides your systems from purchase through retirement, preventing costly surprises along the way. At Clouddle, we’ve seen organizations cut unexpected downtime by half simply by implementing basic lifecycle practices.

This guide walks you through the essentials.

Key Stages of the IT System Life Cycle

Planning and Acquisition: Start With the Right Foundation

Life cycle management isn’t a single action-it’s five distinct phases that repeat across your entire infrastructure. The first phase is planning and acquisition, where you define what systems you actually need and set a realistic budget. Most organizations skip this step or rush through it, then spend the next five years managing the wrong equipment.

You should document the expected lifespan, support costs, and performance requirements before any purchase happens.

Deployment: Establish Your Baseline

The second phase is deployment, where systems go live in your environment. This is when you establish baseline performance metrics and configure monitoring tools to track health from day one. Without this baseline, you won’t know when performance degrades because you’ll have nothing to compare against.

Operation and Maintenance: Where Most Effort Goes

The third phase is operation and maintenance, which consumes a significant portion of IT team effort. This includes regular updates, security patches, and preventive maintenance that keeps systems running smoothly. Organizations that skip scheduled maintenance see failure rates increase according to industry reports on infrastructure management.

Optimization: Improve What You Have

The fourth phase is optimization, where you monitor performance data and make adjustments to improve efficiency and reduce costs. This phase separates organizations that control their infrastructure from those that simply react to problems.

Retirement and Replacement: Plan Ahead

The final phase is retirement and replacement, which happens when systems reach end-of-life. Many organizations delay this phase too long, holding onto outdated equipment that consumes support resources and creates security vulnerabilities. A clear retirement plan prevents this problem and lets you budget for replacements in advance rather than scrambling for emergency funding.

Real Obstacles Block Implementation

Organizations face real obstacles when implementing these phases across large environments. Lack of visibility into what systems exist and their current state represents the biggest problem-you cannot manage what you don’t track. Incomplete documentation means replacement decisions get made without historical context about performance or costs. Budget constraints force difficult choices between maintaining aging systems and investing in upgrades. Staff turnover means knowledge about specific systems walks out the door, leaving gaps in your maintenance schedules and update procedures.

These obstacles explain why many organizations struggle with life cycle management. The good news is that structured processes and the right tools eliminate most of these barriers.

How to Build a System You Can Actually Track

Create an Inventory That Actually Works

Documentation failures destroy life cycle management before it starts. Without knowing what systems exist, their purchase dates, support contracts, or performance history, you manage blind. Start by conducting a complete infrastructure audit to identify every device, server, and application in your environment. This isn’t busywork-organizations that maintain accurate inventories report fewer unexpected outages.

Create a centralized repository that captures system name, hardware specifications, purchase date, warranty expiration, last maintenance date, and assigned owner. Update this inventory quarterly, not annually, because systems change faster than most teams realize. Assign clear ownership so someone is accountable when a system falls out of compliance or needs attention. Without ownership, documentation becomes a graveyard of outdated information that nobody trusts.

Schedule Maintenance Based on Real Behavior

Maintenance schedules fail when they’re generic or disconnected from actual system behavior. Instead of following vendor recommendations blindly, base your schedule on your environment’s specific demands and failure patterns. If a particular server experiences degradation after 45 days of operation, schedule maintenance at day 40 rather than waiting for a standard 60-day cycle.

Track which patches cause problems in your infrastructure so you can avoid repeating mistakes across multiple deployments. This historical data transforms maintenance from guesswork into informed decision-making. Your team learns what works in your specific environment rather than applying one-size-fits-all approaches that often fail.

Monitor Performance Continuously

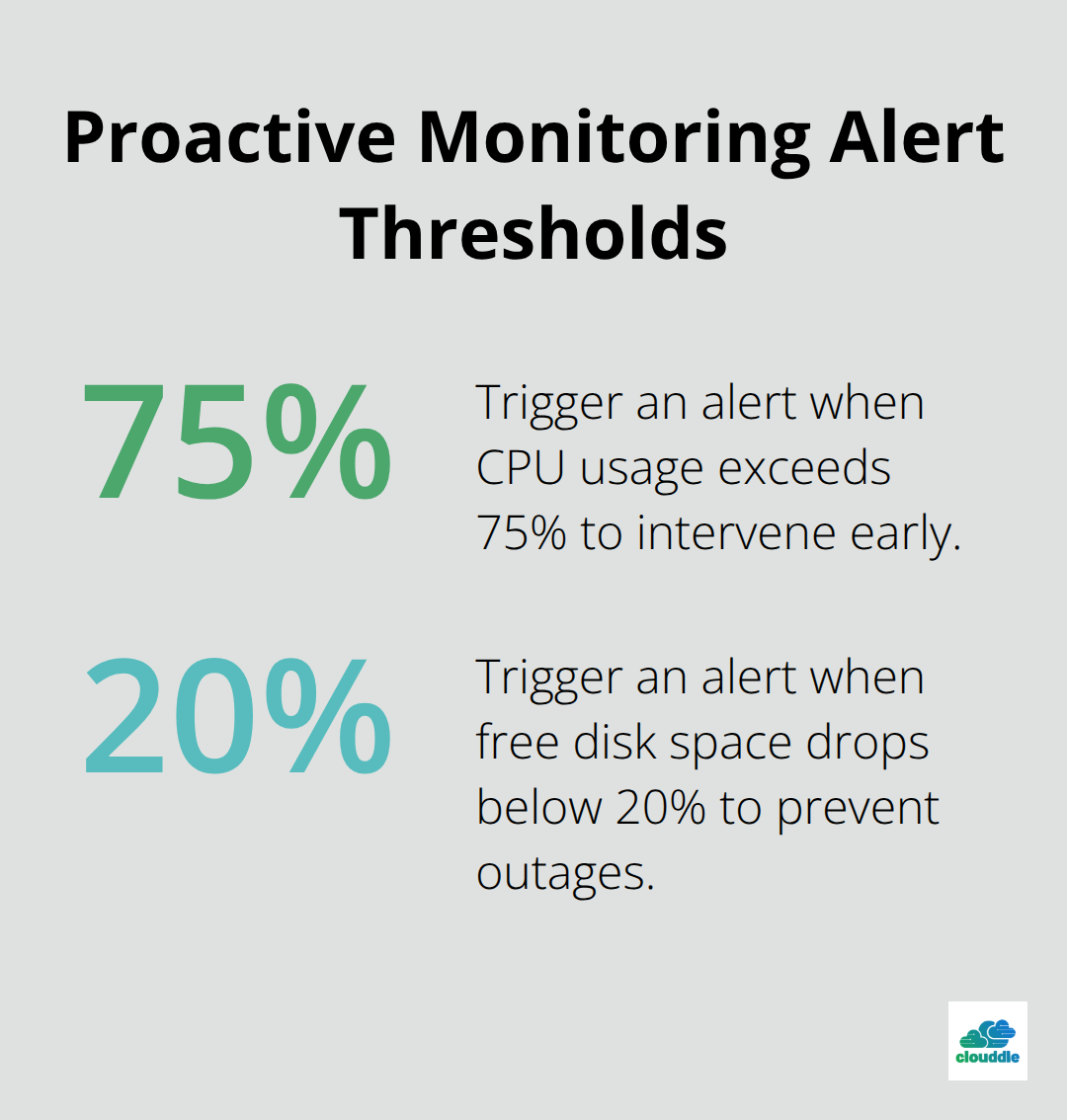

Performance monitoring should run continuously, not as a quarterly exercise-automated tools flag issues before they escalate into downtime. Configure alerts for CPU usage above 75%, disk space below 20% free, and memory pressure spikes so your team responds before users notice problems.

Document what each alert means and what action resolves it, turning reactive troubleshooting into predictable response procedures. This structured approach transforms maintenance from a reactive scramble into a predictable operational rhythm. Your team stops fighting fires and starts preventing them.

With accurate tracking and proactive monitoring in place, you’re ready to tackle the financial side of life cycle management-where structured practices translate directly into measurable cost reductions.

What Life Cycle Management Actually Saves

Downtime Costs Far More Than Most Teams Realize

Downtime costs money in ways most IT departments underestimate. Organizations that implement structured life cycle management cut unexpected failures dramatically because preventive maintenance catches problems before they cascade into outages. When you monitor system health continuously and schedule maintenance based on actual performance data rather than vendor timelines, your team stops fighting emergencies and starts controlling when maintenance happens. A manufacturing facility running 24/7 operations cannot afford reactive repairs, so they schedule maintenance during planned windows when production naturally pauses. This approach transforms maintenance from a disruptive crisis into a predictable operational rhythm that costs far less than emergency repairs conducted under pressure with premium labor rates.

Extended Equipment Lifespan Multiplies Your Investment Value

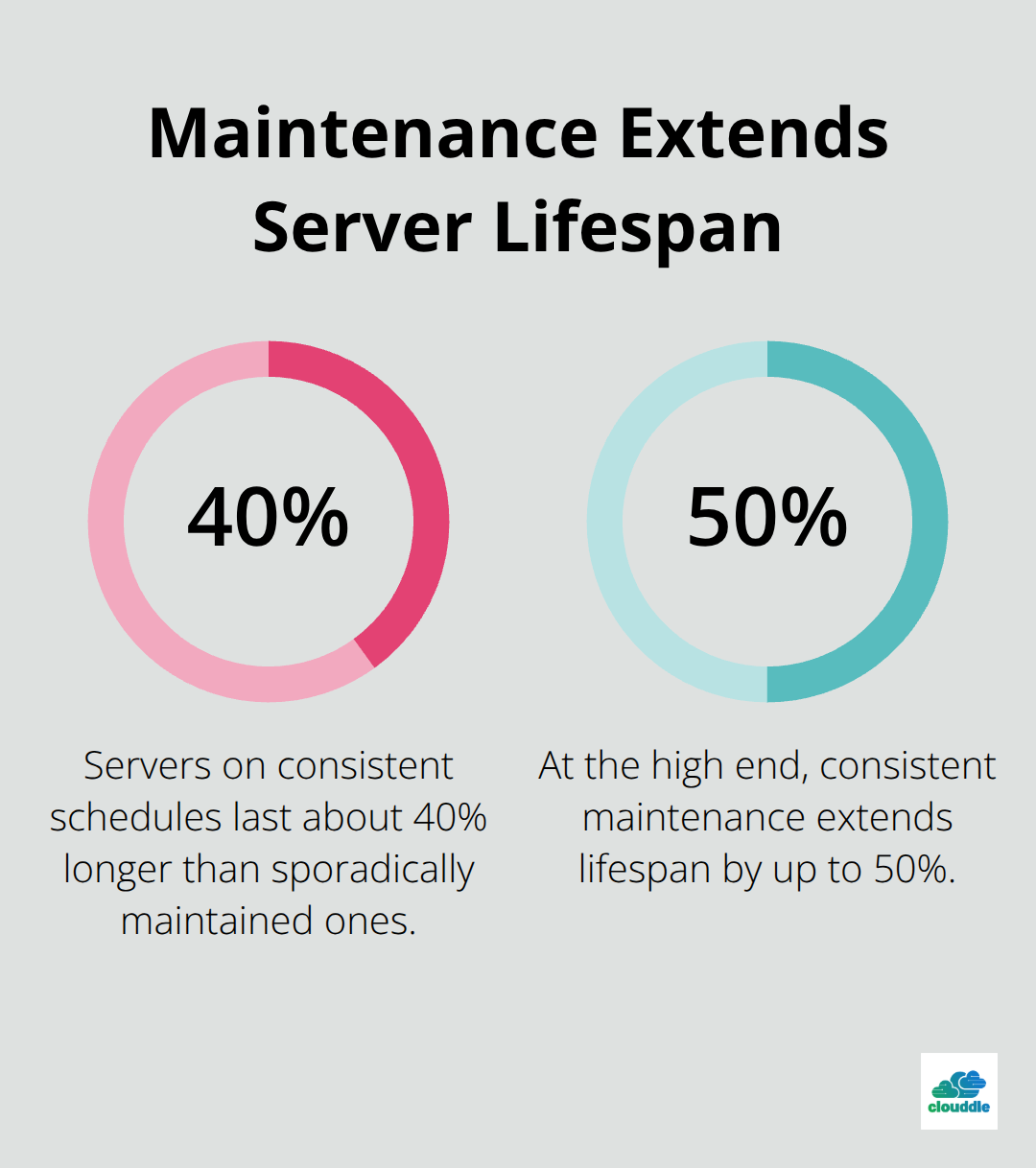

Equipment lifespan directly correlates with maintenance quality, and this relationship has measurable financial impact. Servers maintained on consistent schedules last 40 to 50 percent longer than those receiving sporadic attention, according to infrastructure management studies.

This means your initial hardware investment generates value for additional years instead of becoming obsolete or failing prematurely. A $15,000 server lasting seven years instead of five adds roughly $4,300 in additional value, and this calculation multiplies across dozens or hundreds of devices in typical environments.

Emergency replacements also force you to accept whatever inventory distributors have available rather than selecting optimal specifications for your workload, often resulting in oversized or undersized hardware that wastes budget or creates performance problems. Life cycle management lets you plan replacements strategically, purchasing the right equipment at the right time rather than scrambling when critical systems fail unexpectedly.

Support Costs Escalate Without Strategic Planning

Your team also avoids the hidden costs of extended support contracts for aging equipment, which typically increase 15 to 25 percent annually as manufacturers charge premium rates for legacy systems approaching end-of-life. Organizations that plan equipment retirement in advance (rather than holding onto outdated systems) reduce their total cost of ownership significantly. Strategic replacement cycles prevent the scenario where you maintain expensive legacy hardware that consumes disproportionate support resources while delivering diminishing performance returns.

Final Thoughts

Life cycle management in IT systems transforms how organizations spend money and manage risk. The five phases-planning, deployment, operation, maintenance, optimization, and retirement-create a framework that prevents the costly mistakes most IT departments make by reacting instead of planning. Organizations that implement these practices cut unexpected downtime, extend equipment lifespan by 40 to 50 percent, and avoid the escalating support costs that drain budgets for aging systems.

Start with three immediate actions. Conduct a complete infrastructure audit and build a centralized inventory that tracks every system, its purchase date, warranty status, and maintenance history. Replace generic maintenance schedules with plans based on your actual system behavior and failure patterns, then deploy continuous performance monitoring with automated alerts so your team responds to problems before users experience outages.

The financial impact compounds over time-a single server lasting seven years instead of five generates thousands in additional value, and this multiplies across your entire infrastructure. Organizations winning in their markets aren’t the ones with the newest equipment; they’re the ones controlling infrastructure costs and preventing the downtime that damages reputation and revenue. Visit Clouddle to explore how managed IT services can accelerate your implementation of life cycle management in IT and deliver measurable results.