Getting your operations to run like a well-oiled machine isn’t about just one thing. It’s really a combination of mastering three core areas: sharpening your processes, making smart technology choices, and truly enabling your team. This isn’t just about cutting costs—it’s about building a more intelligent, resilient business that consistently delivers value.

Your Foundation for Improving Operational Efficiency

Before you even think about new software or massive overhauls, you have to get clear on what “operational efficiency” actually looks like for your business. It’s not about speed for speed’s sake. It’s about doing the right things more effectively.

When you nail this, the benefits ripple through the entire company. Your bottom line improves, sure, but so does team morale and customer satisfaction. It’s all connected.

Think of it as building a framework for sustainable growth from the inside out. A business that runs smoothly can pivot when the market shifts and scale without descending into chaos. Most importantly, it frees up your people from mind-numbing, repetitive tasks so they can focus on work that actually moves the needle. Getting into this mindset is the real first step.

The Three Pillars of Efficiency

To turn this idea into something you can actually act on, I’ve always found it helpful to break it down into three pillars. Each one reinforces the others, and together they create a powerful synergy that drives real results. If you’re wondering where to start, start here.

These three areas provide a simple yet powerful framework for building a more efficient operation. Let’s lay them out clearly.

The Three Pillars of Operational Efficiency

| Pillar | Core Focus | Example Action |

|---|---|---|

| Streamlined Processes | Identifying and removing bottlenecks, redundant steps, and manual tasks. | Mapping out the entire customer onboarding journey to find and cut out unnecessary paperwork. |

| Strategic Technology | Using automation, cloud, and networking as enablers for better processes. | Implementing a shared cloud drive to replace emailing files back and forth, ensuring version control. |

| Empowered People | Giving your team the right training, tools, and autonomy to excel. | Providing project management training so team members can lead initiatives with confidence. |

Focusing on these interconnected areas ensures you’re building a balanced and sustainable system for improvement, not just applying temporary fixes.

An efficient operation doesn’t just save money—it creates capacity. By reducing wasted time and effort, you give your team the bandwidth to innovate, solve complex problems, and deliver exceptional customer experiences.

Ultimately, these elements are what allow a business to work smarter, not just harder. If you want to go even deeper, there are some great comprehensive strategies to improve operational efficiency that explore these concepts in more detail.

See Your Workflows Clearly to Spot the Real Bottlenecks

You can’t fix what you can’t see. Before you start chasing efficiency, you need an honest, clear picture of how work actually moves through your business—not just how you think it does. This is where getting visual with your workflows, often called process mapping, becomes so incredibly useful.

This isn’t about creating some overly complicated, jargon-filled chart. It’s about getting the right people in a room and sketching out a process from the very beginning to the final hand-off. I’ve seen this simple exercise uncover shocking inefficiencies that have been hiding in plain sight for years.

The key is to involve the people who do the work every single day. Their perspective from the trenches is gold. Ask them to walk you through a typical task, from the moment a customer makes a request to the final delivery. Your job is to document every single action, every decision, and every time work gets passed from one person to another.

Finding the Hidden Problems

With a visual map in hand, you can start asking the tough questions that lead to real breakthroughs. It takes you out of the world of guesswork and into the realm of facts.

- Where are the traffic jams? Look for the points where work just sits there, waiting for someone’s approval or input.

- Are we doing the same thing twice? You’d be surprised how often you find steps being repeated by different people or departments.

- Which steps add zero value? Be ruthless here. Identify any activity that eats up time and resources but doesn’t actually improve the final product or service.

I once worked with a logistics company that did exactly this. By mapping their order fulfillment process, they found that their drivers were sitting idle for an average of 45 minutes—just waiting for paperwork to be manually signed off by three different managers. It was a massive, completely invisible bottleneck that was costing them a fortune.

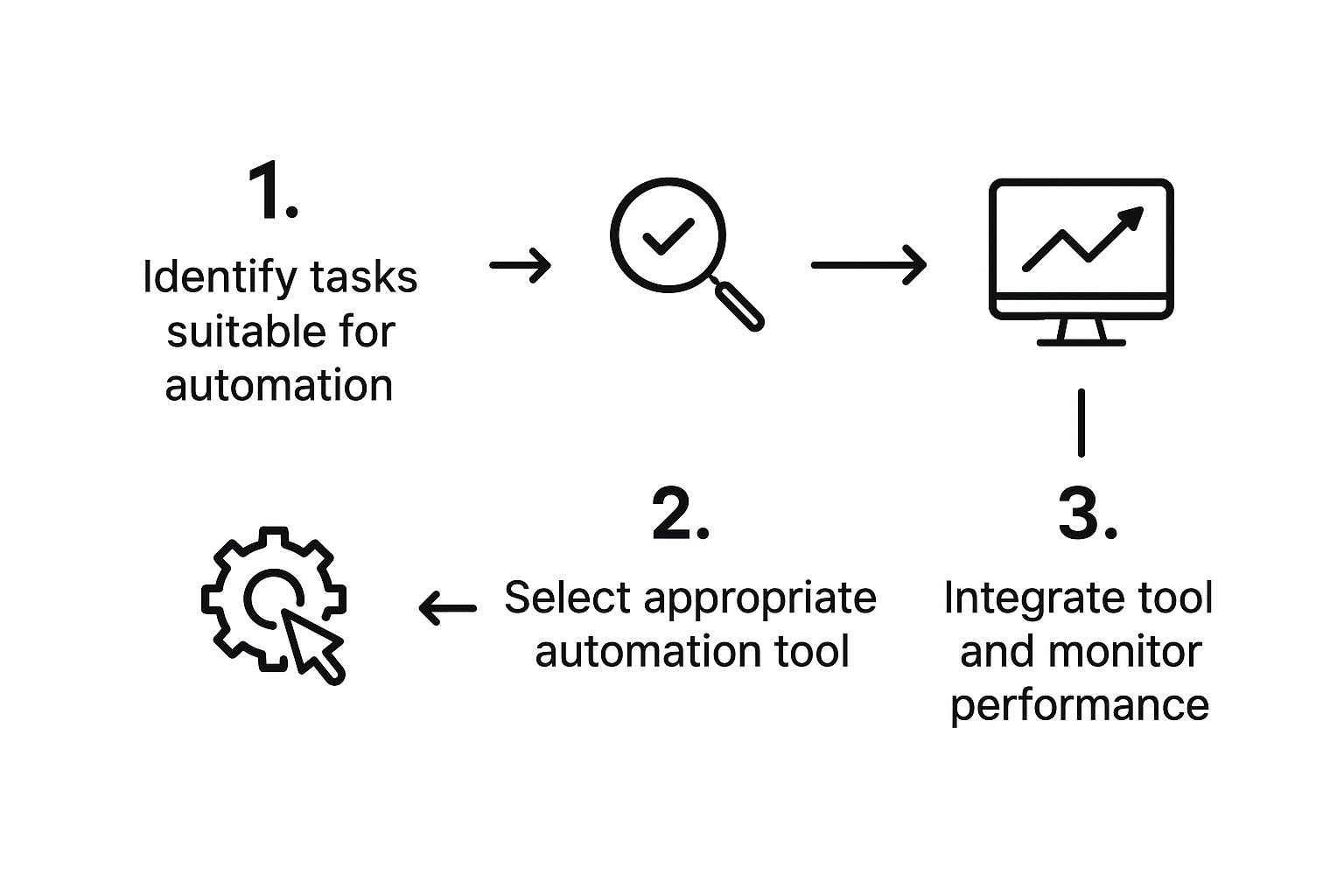

This simple infographic really nails the core idea of using visualization to drive automation and efficiency.

As you can see, the whole process hinges on identifying the right opportunities first, long before you ever pick a tool or start an integration project.

Turning Insight Into Action

Once the logistics company saw the problem laid out visually, the solution was obvious. They ditched the manual sign-offs and brought in a simple digital approval system that managers could use on a tablet.

That one change slashed the average wait time from 45 minutes to less than five. They were suddenly able to handle significantly more deliveries every day without buying a single new truck or hiring another driver.

The most powerful thing about process mapping is that it turns abstract problems into concrete, visual challenges your team can actually solve together. The conversation changes from a vague “we need to be faster” to a focused “how do we eliminate this specific delay right here?”

This is the bedrock of any real improvement initiative. By truly understanding your starting point, you create a baseline. From there, you can pinpoint the areas where a change—whether it’s a small process tweak, a new piece of tech, or just moving people around—will have the biggest impact. Getting that visual clarity is step one to building a truly efficient operation.

Using Automation to Reclaim Your Team’s Time

Once you’ve mapped out your workflows, you’ll start to see patterns. Certain tasks pop up over and over again—the repetitive, rule-based jobs that eat up your team’s day. This is the perfect entry point for automation, not as a way to replace people, but to free them up.

Thankfully, automation isn’t just for huge corporations with massive IT budgets anymore. Modern, accessible tools have put incredible capabilities within reach for businesses of all sizes.

The real goal here is to get your skilled employees away from the soul-crushing work of manual data entry, copy-pasting between apps, and cranking out the same old reports. This lets them focus their brainpower on the strategic work that actually pushes the business forward.

Identifying the Best Automation Candidates

Let’s be clear: you can’t—and shouldn’t—automate everything. The sweet spot is any task that is highly repetitive, rule-based, and high-volume. I’m talking about those daily or weekly chores that are critical for operations but that nobody on your team enjoys doing.

Here are a few classic examples of tasks just begging to be automated:

- Data Entry and Migration: Think about manually moving a lead’s info from a website contact form into your CRM.

- Report Generation: Pulling the same sales figures every Monday morning to build a spreadsheet for the leadership team.

- Invoice Processing: Copying details from a vendor invoice PDF into your accounting software.

- Employee Onboarding: Sending the standard welcome packet, setting up new user accounts, and scheduling orientation.

This isn’t just a niche idea; it’s a massive global trend. Companies are jumping on low-code automation tools to handle exactly these kinds of jobs. By 2025, it’s predicted this shift will save an incredible amount of time, slash error rates, and let businesses move their people from tedious work to strategic thinking. For a deeper dive, check out this insightful article on 2025 efficiency trends.

A Practical Automation Scenario

I see this all the time. A finance team spends about 10 hours every single week just processing invoices. An employee has to watch an inbox, open each PDF, manually type the vendor name, invoice number, and amount into the accounting system, and then save the file in the right place.

It’s painfully slow, typos are inevitable, and honestly, it’s a complete waste of a talented person’s time.

With a fairly simple automation tool, you can completely overhaul this process. You could set up a bot to:

- Watch the dedicated “invoices” email inbox.

- Automatically download and read every new PDF attachment.

- Use character recognition to pull out the key data points.

- Plug that data directly into the accounting software, flagging anything unusual for a human to check.

- File the processed invoice away in the correct folder, all with a neat, standardized file name.

The most common mistake I see is people trying to automate a broken process. If you automate a workflow that’s already flawed, you don’t fix anything—you just make the mistakes happen faster. Always clean up and simplify the process before you bring in automation.

What’s the outcome? The finance team gets those 10 hours back every week. Suddenly, they have time for deep financial analysis, better forecasting, and contributing to strategic planning—the kind of work that truly affects the company’s bottom line. That’s the real, tangible power of smart automation.

Empowering People for Peak Performance

Processes and technology are critical, but they’re only half the story. The real driver of operational efficiency is, and always will be, your people. I’ve seen it time and again: a disengaged team can sabotage even the most perfectly designed workflow, while a motivated team can find ways to make a flawed one work brilliantly.

Shifting your focus to your team is where you’ll find the most sustainable gains. This isn’t about motivational posters; it’s about creating an environment where people feel trusted, well-equipped, and genuinely motivated to do their best work. When your team is truly engaged, they stop just completing tasks and start actively improving them.

The Clear Link Between Engagement and Output

Don’t mistake employee engagement for a soft, feel-good metric. It has a direct and staggering impact on the bottom line. Globally, lost productivity from disengaged employees bleeds an estimated $8.9 trillion from the economy.

On the flip side, things like flexible work arrangements have a powerful, positive effect. For instance, workers with flexible schedules are reportedly 39% more productive. Even a simple shift to remote work can lead to a 22% jump in deep-focus time. You can dig into more of these numbers and see the real cost of disengagement at myhours.com.

This chart breaks down the core elements that create a genuinely engaged workforce.

As you can see, things like meaningful work, supportive management, and a positive environment aren’t just perks—they are the foundation of high performance.

Arming Your Team with the Right Tools

You simply can’t expect someone to deliver top-tier work if they’re fighting outdated or clunky tools. Giving your team the right technology isn’t a luxury; it’s a non-negotiable part of the deal. The goal is to provide software and hardware that removes friction, not adds to it.

Think about a sales team wrestling with a slow, disconnected CRM. They’ll spend more time battling the system than they do actually selling. Give them a modern, integrated platform, and suddenly they’re free to focus on what they do best: building relationships and closing deals. This is where getting expert help can be a game-changer. Exploring the top benefits of managed IT services for your business can show you how outsourcing tech management ensures your team always has the best tools without the internal headaches.

True empowerment isn’t just about delegating tasks. It’s about delegating ownership and trusting your team to find the best path forward, equipped with the tools they need to succeed.

Building a Culture of Proactive Problem-Solving

Ultimately, driving real efficiency requires a culture where feedback isn’t just accepted—it’s actively sought out. Your frontline employees are the true experts on their own workflows. They’re the ones who see the small, daily bottlenecks that managers often miss entirely.

You need to create simple, clear channels for them to suggest improvements without any fear of pushback. When an employee points out a redundant step in a process, celebrate it. This simple act transforms every team member into a proactive problem-solver, constantly on the lookout for ways to make the business run smoother. It’s this collective, ground-up effort that builds a truly efficient and resilient organization.

Weaving Improvement into Your Company’s DNA

Mapping out your workflows and giving your team the right tools are huge wins, but they’re really just the starting line. If you want to see lasting operational efficiency, you have to make improvement a core part of your company’s culture. It’s about shifting from occasional big projects to an environment where everyone, every day, is on the lookout for a better way to get things done.

This isn’t just a trendy idea; it’s a fundamental shift in how successful businesses operate. We’re seeing more and more companies realize that Operational Excellence (OPEX) isn’t just for the manufacturing floor. In fact, 42% of organizations now apply these improvement strategies across their entire business. That’s a noticeable increase from just 37% a few years ago, proving that top companies understand that real efficiency is a collective effort.

Small Wins, Big Momentum

The best way to get there? Focus on small, consistent changes. This is the heart of the Kaizen philosophy—instead of hunting for one massive, game-changing overhaul, you empower your team to spot and implement tiny improvements day in and day out.

I once saw this in action with a client who started a simple “idea of the month” program. Each team just had to submit one small tweak to reduce waste or save a bit of time. One of the best came from a warehouse employee who suggested rearranging a single, high-traffic shelving unit to shorten the walk for pickers. It sounded trivial, but that tiny change saved the team almost 20 hours of labor every single month.

The magic is in the momentum. When you celebrate these small victories, you build confidence and create a positive feedback loop. People see that their ideas matter, which inspires them to find the next opportunity.

Making Feedback a Two-Way Street

For this to work, you have to make it ridiculously easy for people to share their insights. Forget the dusty old suggestion box or multi-layered approval processes that kill ideas before they even start. You need simple, direct channels for feedback.

Here are a few practical ways to do it:

- Quick Team Huddles: Carve out five minutes in your weekly meetings. Go around the room and have each person share one small thing that got in their way or slowed them down.

- A Digital Idea Board: Use a tool like Trello or even a shared document where anyone can post an idea for a process fix and others can upvote it.

- Dedicated “Fix-It” Time: Block out a couple of hours once a month where teams have the autonomy to work on implementing one of the small improvements they’ve identified themselves.

At the end of the day, all of this is about building a culture of excellence where high standards and smart work are just how things are done. This mindset has to extend beyond your own four walls, too. Your relationships with vendors and partners are a huge part of your operational flow. Getting those right is critical, and we’ve actually put together some advice on IT vendor management best practices to help you strengthen those key partnerships.

When you empower your people and constantly refine your processes—both internally and externally—you build an organization that’s not just efficient, but truly resilient.

How to Measure Your Efficiency Gains

You’ve put in the work to overhaul your processes and tech stack, but how do you know if it’s actually paying off? The old saying, “If you can’t measure it, you can’t improve it,” really holds true here. This is where you close the loop and turn good intentions into tangible results.

The trick is to zero in on the right Key Performance Indicators (KPIs) that truly reflect your business goals. Don’t fall into the trap of tracking vanity metrics; you need numbers that tell a clear story about what’s working and what isn’t.

Choosing KPIs That Matter

For a well-rounded view, you’ll want a mix of operational metrics (how well are we doing the work?) and financial ones (is this making us more profitable?). This balance is crucial. It ensures you’re not just speeding things up but also strengthening your bottom line.

A simple, visible performance dashboard is often the best way to bring these numbers to life. I once worked with a small e-commerce business that was struggling with fulfillment. We decided to track just one core KPI: order-to-ship time. We put it up on a large monitor in the packing area.

Just by making that one number visible, the team became invested. They started brainstorming ways to organize inventory and stage packing materials, which cut their average ship time by nearly 30% in two months. It was a game-changer.

Essential KPIs for Measuring Operational Efficiency

To get you started, here is a selection of key metrics across different business functions. You don’t need to track all of them, but choose the ones that align best with the changes you’ve implemented.

| Category | KPI Example | What It Measures |

|---|---|---|

| Operations | Cycle Time | The total time from the start to the end of a process (e.g., order fulfillment). |

| Productivity | Throughput | The number of units or tasks completed in a given period. |

| Financial | Cost Per Unit/Action | The total expense required to produce one unit or complete one action. |

| Customer Service | First Contact Resolution (FCR) | The percentage of customer issues resolved during the first interaction. |

| Financial | Cost-to-Serve | The total cost of delivering a product or service to a single customer. |

| IT/Tech | System Uptime/Downtime | The percentage of time a critical system is operational and available. |

Tracking metrics like Cost-to-Serve is a core component of many successful IT cost saving strategies, directly linking your operational improvements to financial health.

Remember, the point of measurement isn’t just to build reports that sit in a folder. It’s about finding your next big opportunity. Good data should spark conversations and guide your team toward smarter ways of working.

When you consistently track your performance, you transform efficiency from a one-off project into a core, data-driven habit for your entire organization.

Common Questions About Boosting Efficiency

Where Do I Even Start with Improving Operational Efficiency?

The best place to begin is by simply making your current processes visible. You can’t fix what you can’t see, so the first real step is to map out how work gets done from start to finish.

This is often called process mapping, and it’s invaluable. It gives you an honest, visual blueprint of your operations, instantly highlighting the hidden bottlenecks, duplicated efforts, and other resource drains you never knew you had. Think of it as the bedrock for any meaningful change.

How Can a Small Business Get More Efficient on a Tight Budget?

You don’t need a massive budget to see huge improvements. For small businesses, the key is to focus on low-cost, high-impact changes. A great starting point is automating those repetitive, mind-numbing administrative tasks. There are tons of affordable software tools out there—many with free or very cheap plans designed specifically for small teams.

Another powerful, and often overlooked, strategy is to empower your employees. The people doing the work every day are the real experts. Create a simple way for them to suggest small, practical improvements. These incremental tweaks add up to massive gains over time, all without a big price tag.

Improving operational efficiency isn’t always about expensive technology. Often, the biggest wins come from making small, consistent process adjustments and empowering the people who do the work every day to identify better ways of doing things.

How Can I Actually Measure if Our Efficiency is Getting Better?

You measure success by tracking a handful of specific Key Performance Indicators (KPIs) that directly tie back to what you’re trying to achieve. The trick is not to track everything, but to pick a few metrics that truly matter.

For most businesses, these are the heavy hitters:

- Cycle Time: How long does it take to get something done from the very beginning to the very end?

- Cost-to-Serve: What’s the total expense involved in delivering your product or service to a customer?

- Throughput: How many units, tasks, or tickets can your team complete in a given timeframe (like a day or a week)?

By tracking these KPIs before and after you make a change, you get concrete, undeniable proof of the impact your efforts are having.

Ready to build a more efficient and secure technological foundation for your business? The experts at Clouddle Inc specialize in creating integrated IT, security, and cloud solutions that remove operational friction and drive growth. Discover how our managed technology services can help you work smarter.