Submarine cable installation is one of the most complex infrastructure projects on the planet. These underwater networks carry over 99% of intercontinental data traffic, making them essential for global connectivity.

At Clouddle, we understand that laying cables across ocean floors requires precision, specialized equipment, and careful planning. This guide walks you through every stage of the process, from initial surveys to long-term maintenance.

Planning and Preparing Your Submarine Cable Route

Before any cable touches the ocean floor, you need hard data about what’s actually down there. Desktop studies combine marine charts, geological surveys, and historical seabed data to understand conditions before routing decisions happen. This isn’t guesswork-it’s the foundation that determines whether your project stays on schedule or becomes a nightmare of delays and repairs.

Surveying the Seafloor with Precision Equipment

Engineers map the underwater landscape using side-scan sonar and multibeam sounding to identify obstacles before laying cable. Geotechnical studies reveal seabed soil types like soft sand, hard clay, and rocky terrain that directly affect burial depth and technique. These surveys cost money upfront, but they save exponentially more by preventing equipment downtime and damage during installation.

A pre-lay grapnel run clears the route of debris such as ropes, anchors, and logs to prevent cable damage before the main lay vessel arrives. This step alone has prevented countless failures in projects across the Atlantic and Pacific. The surveys provide the intelligence that transforms a risky operation into a controlled, predictable one.

Designing Routes That Balance Economics and Reality

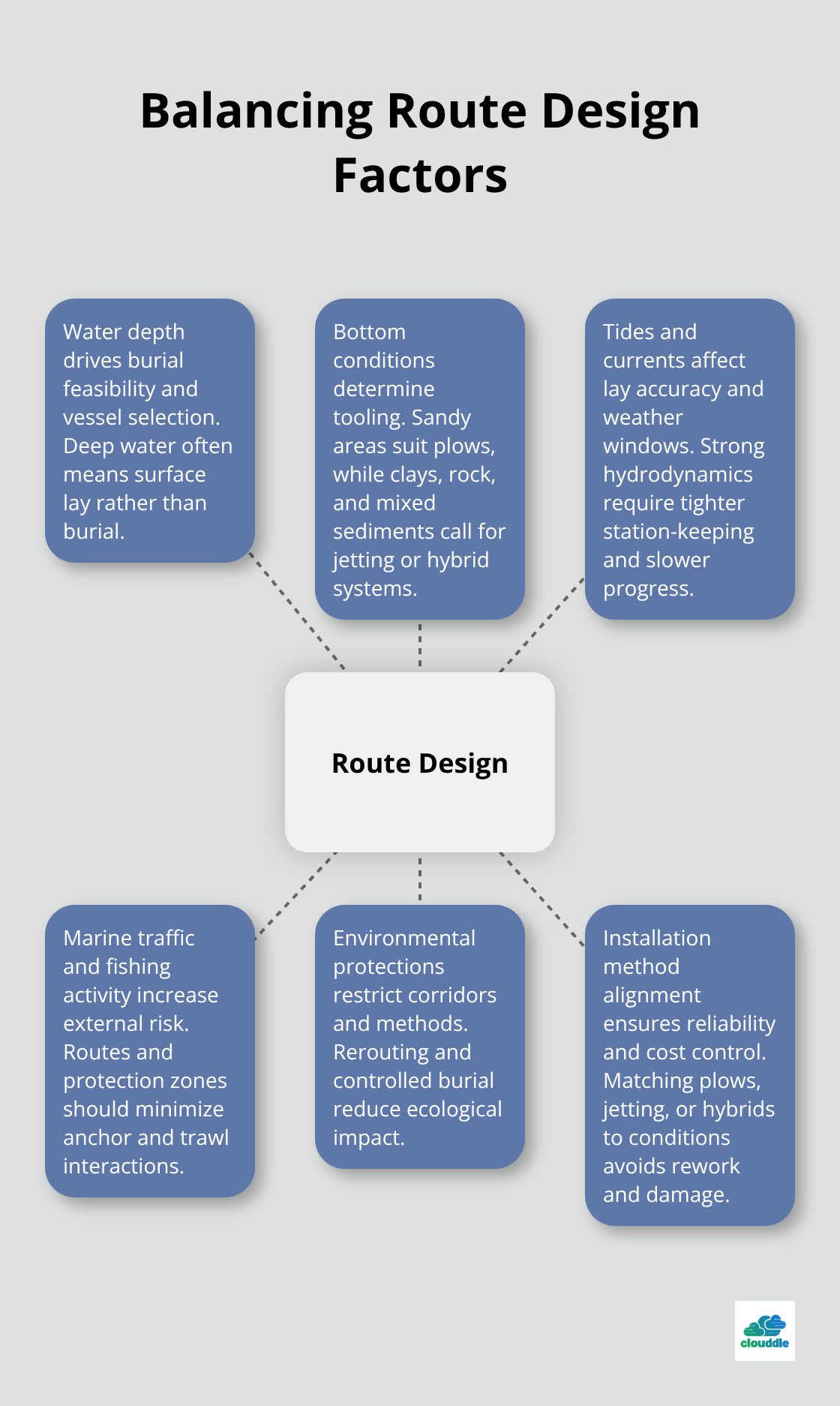

Route design must balance technical, environmental, and economic factors simultaneously-there’s no such thing as a perfect route, only the least problematic one. Water depth, bottom conditions, tides, currents, marine traffic, and environmental protections all compete for attention. An example shows a 30 km power transmission cable from Pulau Ketam to Port Klang buried 14 meters under the seabed, illustrating how deep burial protects against future dredging and ship anchors.

In very deep seas beyond 10,000 meters, burial becomes impractical and cables lay directly on the seabed instead. Routing around protected areas and using burial where feasible reduces environmental impact while maintaining cable protection. Your route design also determines which installation method works best-mechanical plows work on sandy bottoms, jetting systems handle marshes and tidal zones, and hybrid systems adapt to changing conditions. The installation aim is a stronger, more resilient grid that reliably delivers power to consumers, which means your route planning directly impacts decades of future performance.

Securing Permits and Defining Protection Zones

International law under UNCLOS (1982) grants the freedom to install and maintain submarine cables on the high seas and continental shelf, but rights and obligations vary across Exclusive Economic Zones, the continental shelf, and archipelagic waters. Cable Protection Zones (CPZ) are legally defined and marked on nautical charts around completed cables, with infringement carrying serious fines-New Zealand’s example shows penalties up to about $100,000.

The New Zealand HVDC Inter-Island cable operates within a 7-kilometer-wide CPZ, illustrating how well-defined zones prevent human-caused faults from anchors and fishing gear. Start permitting processes early because regulatory approvals take months, not weeks, and delays compound quickly when you have a cable manufacturing schedule and vessel bookings lined up. The Kingfisher Information Service-Offshore Renewable & Cable Awareness (KIS-ORCA) provides online maps of sea infrastructure to raise awareness among fishing operators and others sharing your planned route.

Industry bodies like ICPC (International Cable Protection Committee) and NASCA (North American Submarine Cable Association) issue protective recommendations that regulators expect you to follow. With permits secured, route surveys completed, and environmental assessments approved, you transition from planning to the practical execution phase where specialized vessels and equipment take center stage.

Installation Process and Equipment

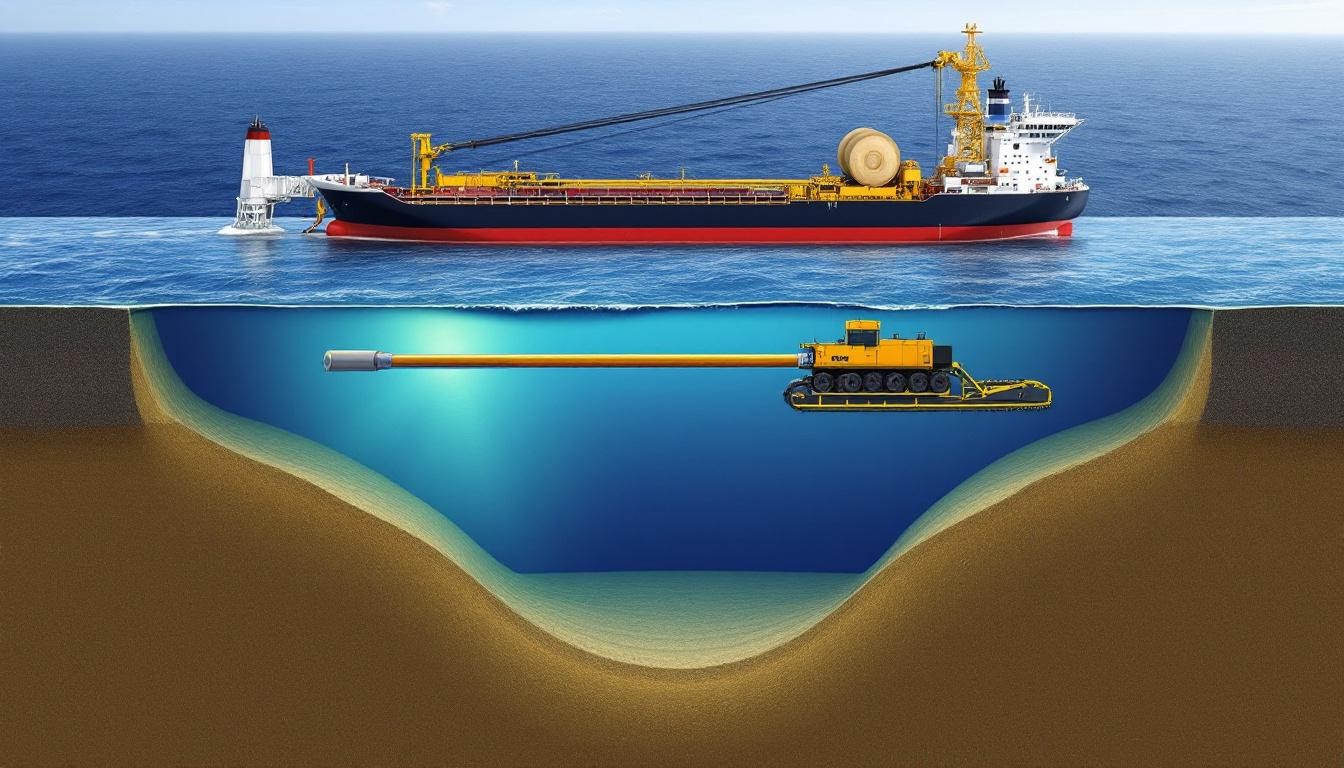

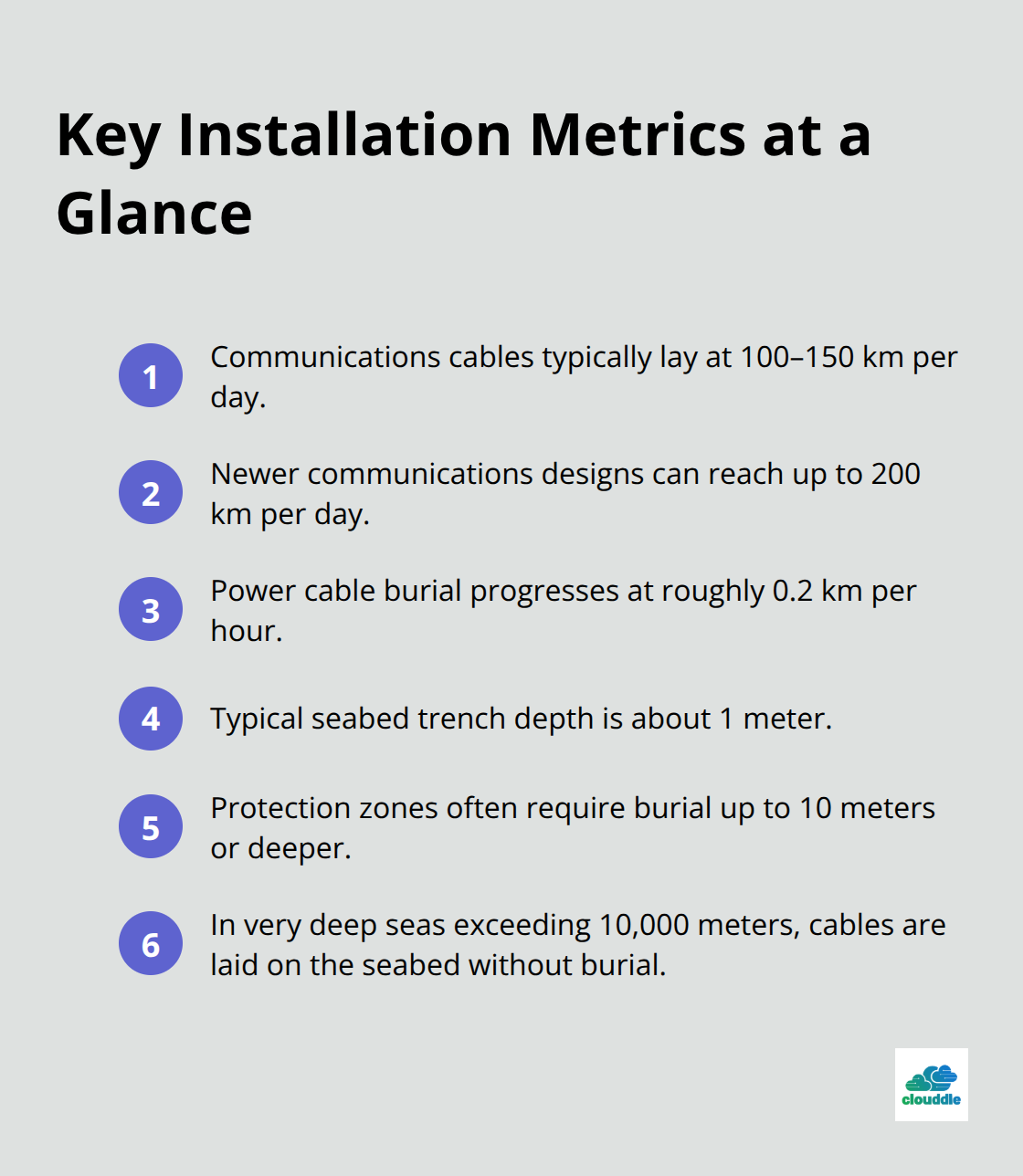

Installing submarine cables demands vessels engineered for precision rather than speed. Specialized cable laying vessels like the Skagerrak, Giulio Verne, Team Installer, and C.S. Sovereign carry powered turntables to manage long lengths of cable without introducing slack or tension spikes that damage insulation. These ships maintain exact location despite currents and waves through dynamic positioning systems, which becomes non-negotiable when burying cable in shallow water or navigating around existing infrastructure. The cable arrives on drums loaded directly onto the vessel, then feeds through a chute system that controls tension as it spools into the water. Laying rates vary dramatically by cable type: communications cables typically move at 100–150 km per day, with newer designs reaching up to 200 km per day, but power cables move far slower at roughly 0.2 km per hour during burial operations because their larger diameter and complex insulation require mechanical plows or jetting systems that cannot rush.

Burial Depth Determines Protection Strategy

The seabed trench typically measures about 1 meter deep for standard installations, though protection zones often demand burial up to 10 meters or deeper. That 30 km power transmission cable from Pulau Ketam to Port Klang sits 14 meters under the seabed specifically because deeper burial prevents future dredging operations and ship anchors from reaching it. Mechanical plows towed on underwater sleds slice a trench and bury the cable beneath displaced sediment, while jetting systems fluidize sediment with water jets for marshes, tidal zones, and deep water environments.

In very deep seas exceeding 10,000 meters, burial becomes impractical and cables lay directly on the seabed instead. Hybrid systems that combine plowing, jetting, and cutting tools adapt to changing bottom conditions across a single route, which means your installation crew needs trained operators for each technique rather than one-size-fits-all methodology.

ROVs and Submersible Equipment Handle Precision Tasks

After the cable reaches the seabed, submersible equipment settles it along the planned path while divers assist in shallow waters. Deep-water operations rely entirely on Remotely Operated Vehicles (ROVs) because human divers cannot function below roughly 300 meters. Post-lay inspection and burial verification uses ROVs to confirm proper laying and burial depth, with jetting tools applied to achieve required protection levels. Precise positioning relies on acoustic instruments like echo-sounders and high-accuracy GPS or differential GPS systems to guide both initial lay and subsequent burial operations. This multi-stage approach costs more upfront than rushing cable onto the seabed, but prevents anchor snags and fishing trawl damage that trigger expensive emergency repairs in remote locations where repair vessels cost tens of thousands daily to mobilize.

Protecting Cables from Anchors and Fishing Gear

Cable Protection Zones (CPZ) legally define areas around installed cables and appear on nautical charts to warn marine traffic. The New Zealand HVDC Inter-Island cable operates within a 7-kilometer-wide CPZ, illustrating how well-defined zones prevent human-caused faults from anchors and fishing gear. Infringement of these zones carries serious fines-New Zealand’s example shows penalties up to about $100,000-and regulators enforce them strictly. The Kingfisher Information Service–Offshore Renewable & Cable Awareness (KIS-ORCA) provides online maps of sea infrastructure to raise awareness among fishing operators and others sharing your planned route. Industry bodies like ICPC (International Cable Protection Committee) and NASCA (North American Submarine Cable Association) issue protective recommendations that regulators expect you to follow throughout installation and operation.

With your cable now secured on the seabed and protected from external threats, the focus shifts to long-term monitoring and maintenance strategies that keep your infrastructure operational for decades.

Maintenance and Protection of Submarine Cables

Submarine cable systems operate for tens of years, which means maintenance strategies determine whether your infrastructure pays dividends or becomes an expensive liability buried under kilometers of ocean. The real challenge isn’t installation day-it’s the years that follow when natural forces and human activity constantly threaten your investment. Routine maintenance includes periodic cable and route surveys that detect tears, wear, and seabed geodynamic changes, along with preventive component replacements and Cable Protection Zone enforcement. Weather and sea conditions dramatically impact maintenance windows, especially in high-latitude operations where ice management extends timeframes significantly.

Monitoring Threats Before They Become Failures

Ship anchors and fishing trawls pose the main threats to submarine cables, which is why protection zones receive legal definition and strict enforcement. New Zealand’s HVDC Inter-Island cable operates within a 7-kilometer-wide CPZ with penalties reaching $100,000 for infringement, demonstrating how seriously regulators treat cable protection. High-resolution geophysical surveys identify emerging threats like shifting sediment patterns or cable exposure where burial has eroded away, allowing operators to schedule maintenance during optimal weather windows rather than reacting to emergencies. The Kingfisher Information Service–Offshore Renewable & Cable Awareness provides online maps of sea infrastructure that help coordinate with fishing operators and shipping interests, reducing accidental damage before it happens.

Industry bodies like ICPC (International Cable Protection Committee) and NASCA (North American Submarine Cable Association) publish protective recommendations that operators should implement as standard practice, not optional extras. ROVs equipped with inspection cameras and jetting tools verify burial depth compliance and identify damage from external contact, revealing whether your cable protection works effectively or whether vessels encroach dangerously close. Regular surveys cost significantly less than emergency mobilizations, yet many operators treat them as optional expenses rather than essential operational requirements.

Locating and Retrieving Damaged Cable Sections

When a cable fault occurs, the repair workflow demands technical precision and coordinated logistics across multiple specialists. Underwater survey equipment narrows the search area, then ROVs with cutting tools sever the cable on both sides of the damage. The broken segment reaches the surface for analysis while a new cable section manufactured to exact specifications waits on deck. Splicing the new segment back into the existing cable requires technicians trained on high-voltage connections and submersible equipment operators working in coordination, then testing procedures confirm electrical continuity before declaring the repair complete.

In very deep water exceeding 10,000 meters, repair complexity multiplies because dynamic positioning vessels must maintain exact location against currents while ROVs operate at crushing pressures where equipment failures become catastrophic rather than inconvenient. The repair timeline typically spans days to weeks depending on water depth and weather conditions, during which your cable sits offline and customers experience service disruption.

Why Prevention Costs Far Less Than Emergency Response

Mobilizing repair vessels costs tens of thousands daily, making fault response timing absolutely critical to minimize service disruption. This reality makes burial protection and cable protection not merely regulatory compliance requirements but economic necessities that directly impact your operational costs and customer satisfaction. The data collected during routine inspections should inform future route planning for new cables, preventing repeated installation of cables in high-risk zones where existing damage patterns show vulnerability.

Final Thoughts

Submarine cable installation represents one of the most demanding infrastructure challenges on Earth, yet the process follows a logical progression from careful planning through decades of operational maintenance. You start with desktop studies and geotechnical surveys that reveal what lies beneath the waves, then design routes balancing technical constraints against environmental and economic realities. Permits take months to secure, protection zones receive legal definition, and specialized vessels arrive with crews trained for precision work in extreme conditions.

The actual laying happens faster than most expect-communications cables move at 100–150 km per day-but power cables crawl at 0.2 km per hour because burial protection demands mechanical plows and jetting systems that cannot rush. Once your cable settles on the seabed, routine surveys detect threats before they become failures, ROV inspections confirm burial depth compliance, and cable protection zone enforcement prevents anchor snags and fishing trawl damage. The submarine cable industry continues advancing with hybrid burial systems adapting to changing seabed conditions and improved ROV technology reducing repair timelines in deep water.

These developments matter because submarine cables carry over 99% of intercontinental data traffic, making their reliability non-negotiable for global connectivity. Your cable infrastructure must operate reliably for tens of years, which means you should treat maintenance as essential operational strategy rather than optional expense.

At Clouddle, we provide managed IT, networking, and security solutions designed to keep your operations running without interruption.