Underwater cable installation is one of the most complex infrastructure projects in the world. A single mistake during planning or execution can cost millions and disrupt global communications for months.

At Clouddle, we’ve seen firsthand how proper installation techniques separate successful projects from costly failures. This guide walks you through every critical step, from initial surveys to long-term maintenance.

Planning the Route and Securing Approvals

Before a single meter of cable enters the water, you need comprehensive data about what lies beneath. Desktop studies form the backbone of this phase-they review marine charts and geological surveys and historical seabed data to map the optimal route. This isn’t theoretical work; it directly determines whether your cable survives thirty years or fails within five. Side-scan sonar and multibeam sounding reveal the underwater landscape in detail, identifying obstacles and seabed contours that influence burial depth and protection strategies. Geotechnical studies expose sediment types-soft sand, hard clay, rocky terrain-each demanding different burial techniques. A cable in soft sand requires different protection than one in rocky substrate, and getting this wrong means expensive remediation later.

Environmental Sensitivity Shapes Route Selection

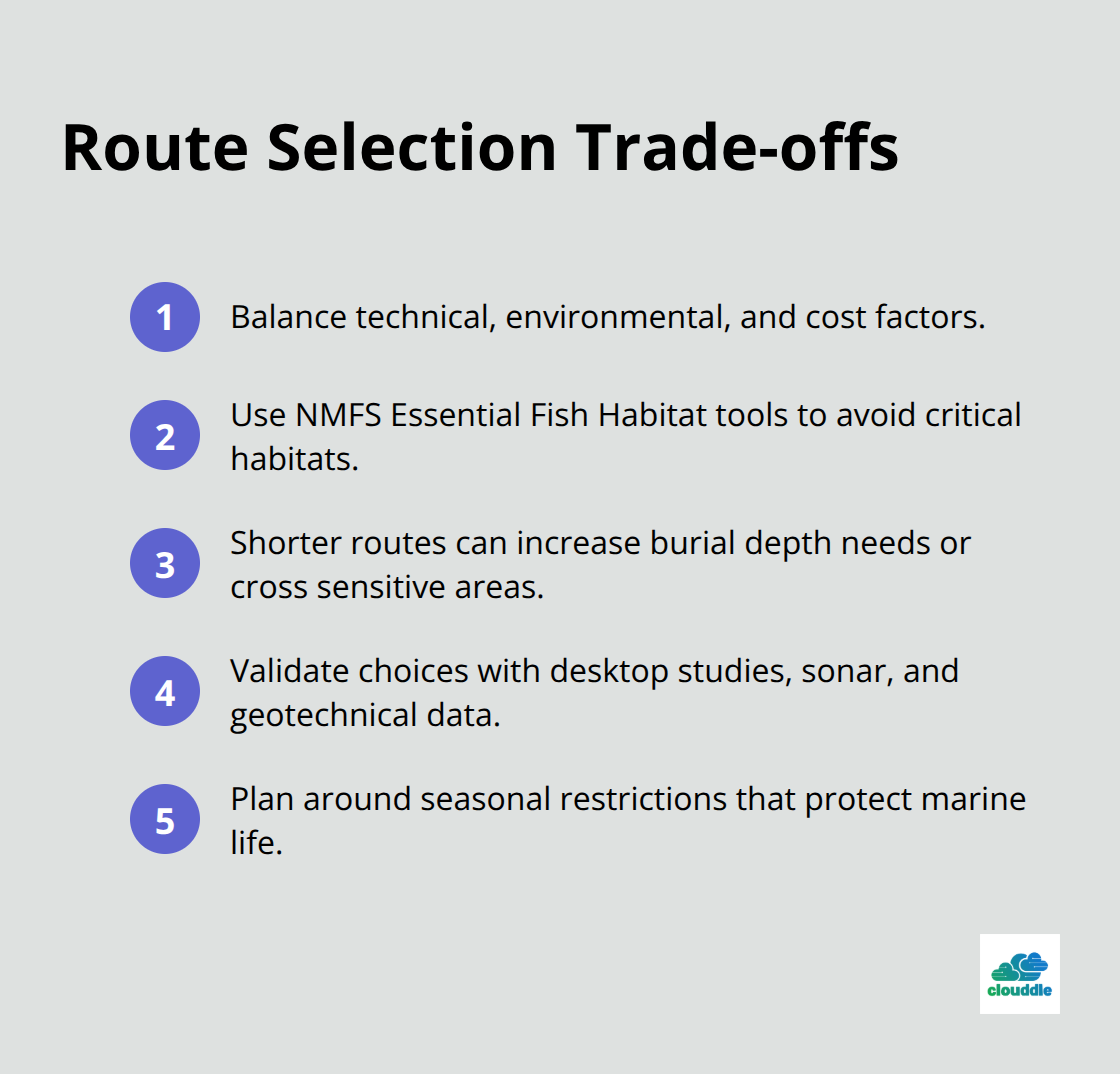

Environmental mitigation involves routing around protected areas; with 17 National Marine Sanctuaries currently in place and four additional designations planned, regulatory bodies scrutinize every routing decision. The route must balance technical requirements, environmental sensitivity, and cost. Shorter routes cost less to install and maintain, but they may cut through sensitive habitats or require deeper burial in challenging seabed conditions. The NMFS Essential Fish Habitat Mapper identifies critical habitats that should shape your routing strategy.

You can use this tool to avoid spawning grounds and feeding areas that regulators protect under federal law. Environmental impact reviews involve Endangered Species Act consultations, and seasonal restrictions protect marine mammals and spawning fish during vulnerable periods.

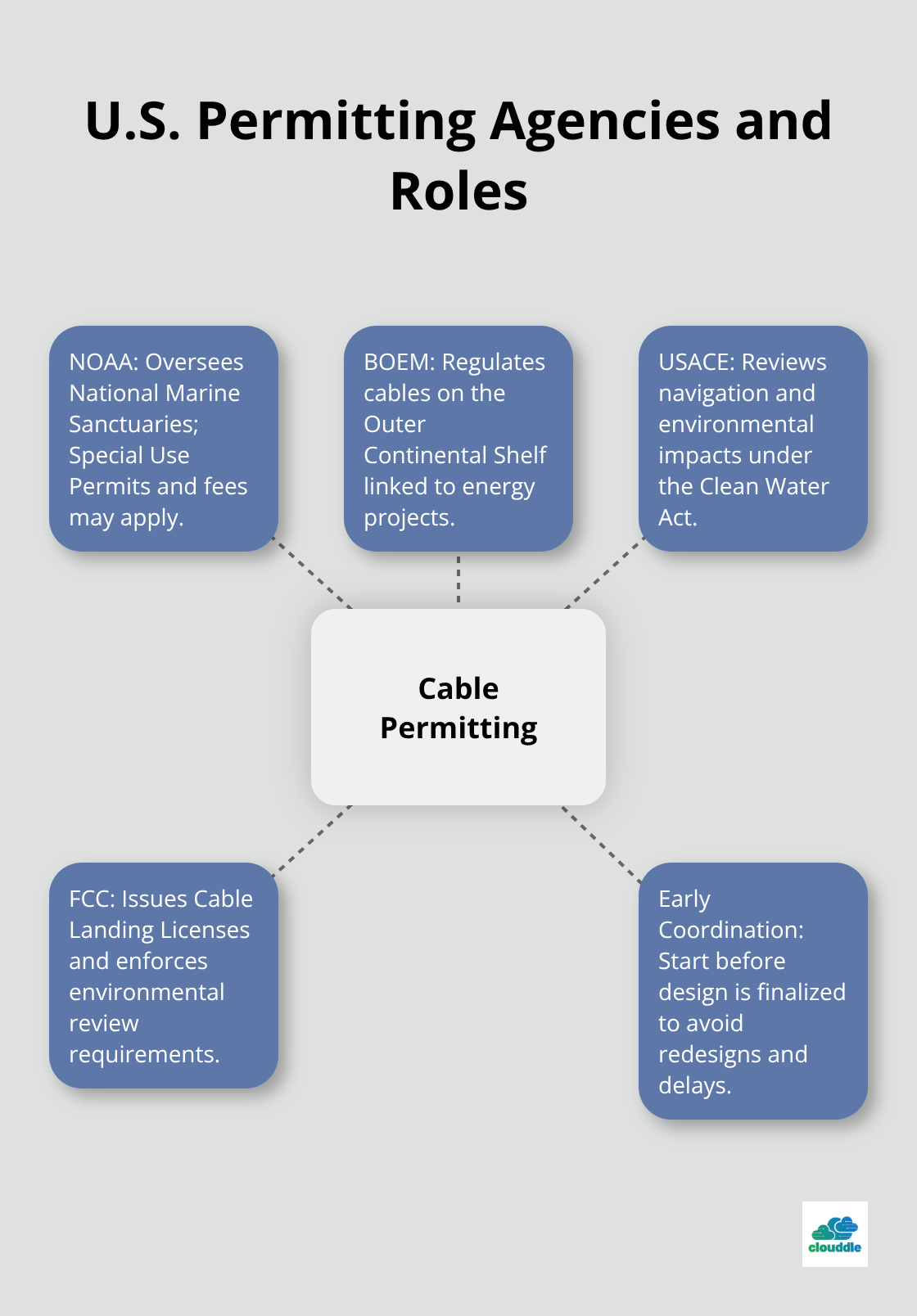

Navigating the Regulatory Maze

The regulatory landscape spans multiple federal agencies, each enforcing different rules. NOAA handles National Marine Sanctuaries and may require Special Use Permits with associated fair market value fees. BOEM regulates cables on the Outer Continental Shelf linked to energy projects. USACE reviews navigation and environmental impacts under the Clean Water Act. The FCC issues Cable Landing Licenses and enforces environmental review requirements. This complexity means you should start permitting discussions early-not after design is finalized. Early interagency coordination prevents costly redesigns and delays later in the project.

Burial Depth and Installation Timing

Burial depth varies significantly by water depth and risk exposure. Shallow waters typically require 0.6 to 1.5 meters of burial, while depths exceeding 2,000 meters often skip burial altogether. Installation timing matters too; you must align work schedules with seasonal restrictions that protect marine life. A comprehensive preparation checklist includes mapping sensitive habitats, selecting the shortest safe route following industry best practices, planning appropriate burial depth, and establishing monitoring plans before work begins. These decisions directly affect how your installation team approaches the actual cable lay operation.

Installing Cable in the Water

Selecting the Right Vessel and Equipment

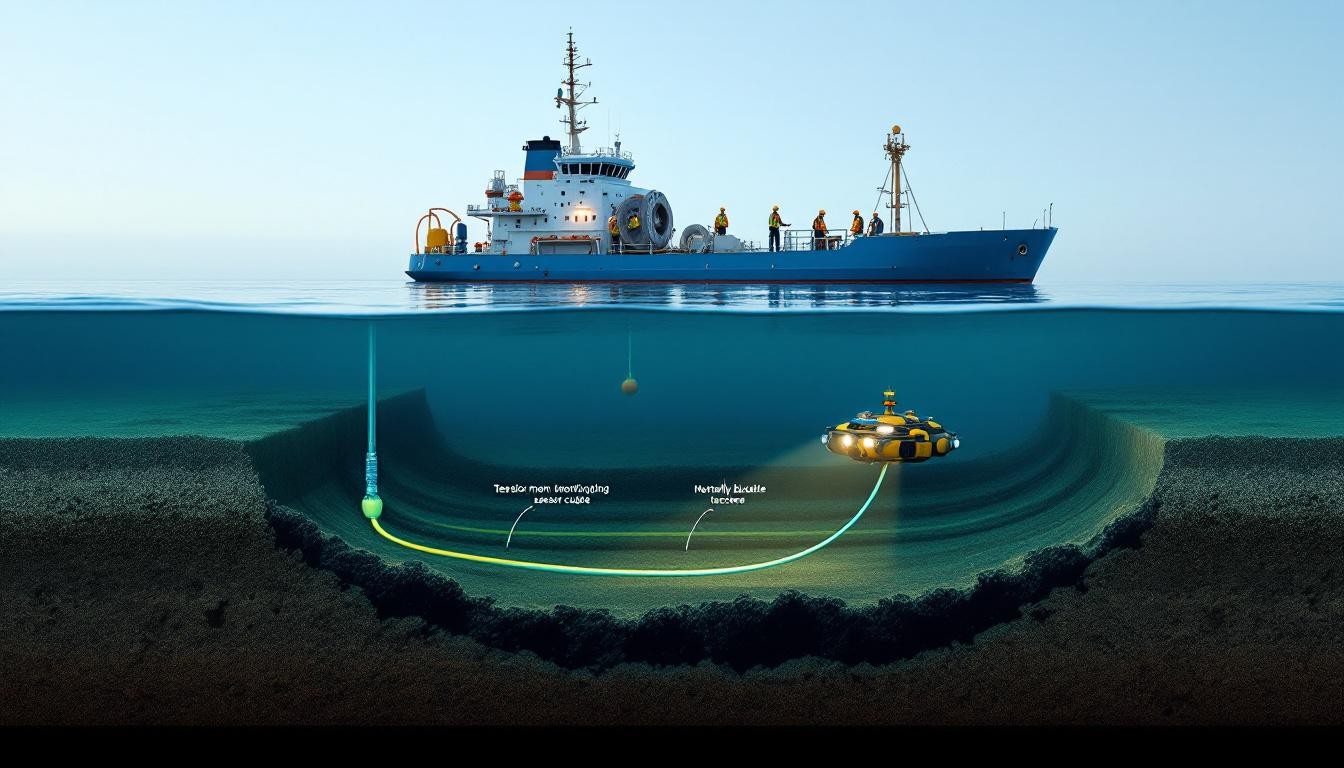

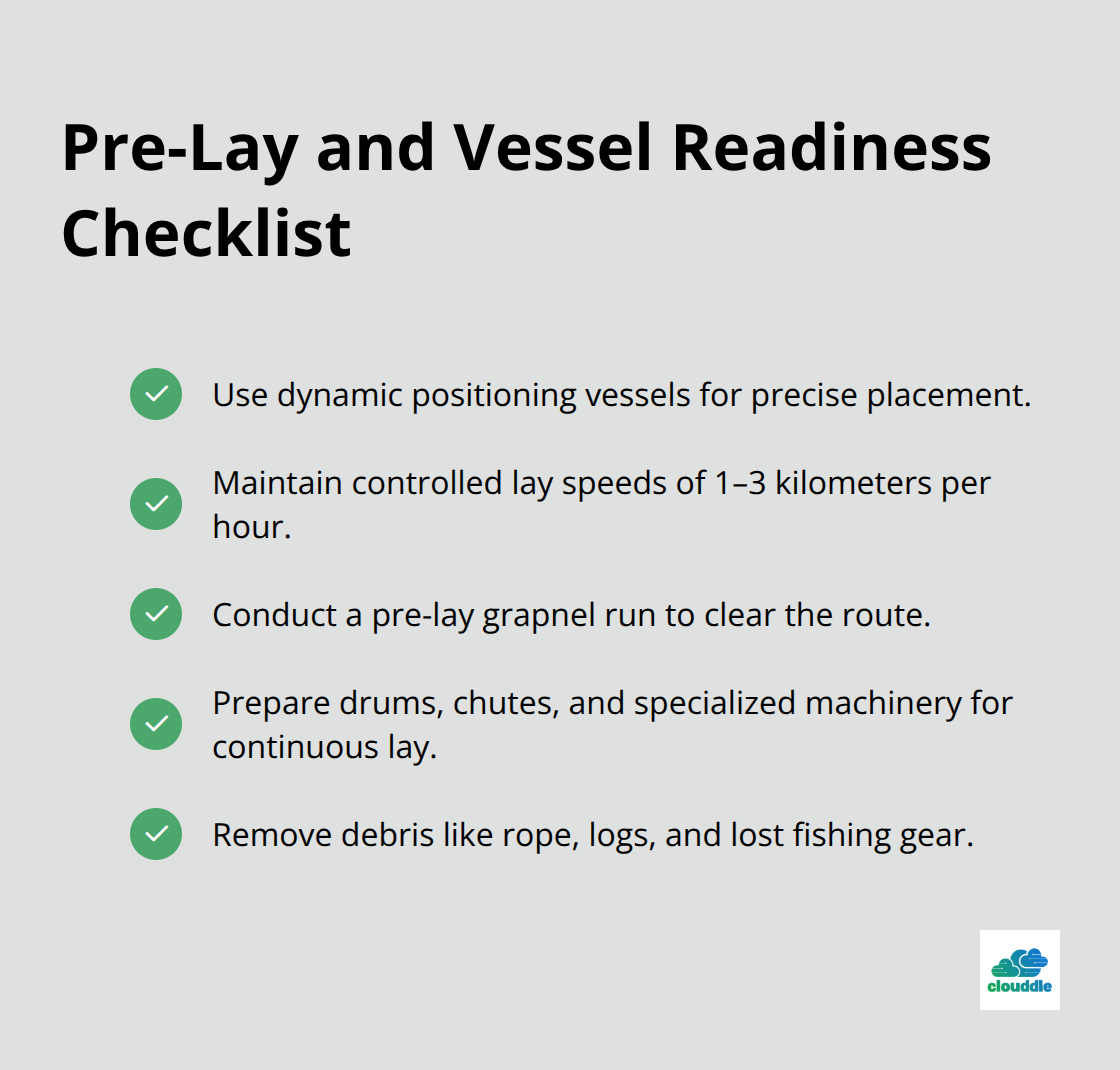

The vessel you select determines whether your installation stays on schedule and within budget. Dynamic positioning ships maintain precise placement even in rough seas, critical for accuracy in depths exceeding 2,000 meters where currents and pressure create unpredictable conditions. These vessels carry cable wound on massive drums and feed it through a chute as they travel the planned route at speeds between 1 and 3 kilometers per hour. Specialized machinery transforms what would otherwise be an impossible task into a controlled operation. Before the cable enters the water, a pre-lay grapnel run clears the burial path of debris like rope, logs, and lost fishing gear that could damage equipment or the cable itself.

This clearing step is not optional in waters where fishing activity is heavy.

Burial Methods for Different Seabed Conditions

Once the seabed is clear, the actual lay operation begins with cable ploughs or jetting systems deployed behind the laying vessel. Mechanical trenching ploughs slice a narrow trench, lift sediment in front of the cable, and bury it beneath the disturbed material in a single pass. Jetting systems use high-pressure water to fluidize sediment, allowing cables to sink into soft substrates. Hybrid systems combine both methods to handle varied bottom conditions-soft sand requires different treatment than hard clay or rocky terrain. Burial depth depends on water depth and risk exposure with shallow waters needing protection against fishing trawls and ship anchors, while abyssal zones beyond 2,000 meters often rest directly on the seabed without burial.

Verification and Shore-End Installation

Post-lay inspection and burial verification uses remotely operated vehicles equipped with high-resolution cameras and jetting tools to confirm proper placement and deepen burial where necessary. This verification focuses on high-risk zones like cable crossings and areas near shipping lanes. Shore-end burial near landing sites frequently requires divers working in shallow water to ensure the cable transitions safely from the vessel to land infrastructure. Direct float methods work for some projects where the cable floats from the vessel to the landing point, while pre-laid approaches use barges to position cable sections before final burial.

Timing, Expertise, and Environmental Constraints

The specialized nature of this work means crew expertise matters enormously. Technicians must understand seabed geology, vessel dynamics, and real-time decision-making when unexpected conditions emerge. Submarine cable installation and maintenance are extremely difficult, requiring specialized equipment and expertise for deep-sea operations. The extreme pressure at depth, near-freezing temperatures, strong currents, and challenging seabed terrain influence every design choice and handling method. Installation is the most environmentally sensitive phase due to seabed disturbance and increased vessel activity, so scheduling work outside seasonal restrictions protecting spawning fish and marine mammals prevents costly delays and regulatory violations. Weather windows narrow dramatically in certain seasons and regions, compressing the timeline available for installation. A cable system that takes three months to install in summer conditions might require six months during winter due to rough seas and limited visibility. This timeline expansion directly increases costs and extends the period when marine traffic must avoid the installation zone. Once your cable is in place and verified, the real test begins-keeping it operational through decades of exposure to shifting seabeds, fishing activity, and natural hazards that threaten even the most robust installations.

What Derails Underwater Cable Projects

Site surveys and geotechnical data Shape Success

Skipping proper site surveys destroys project budgets faster than almost any other mistake. Teams that rush through desktop studies or rely on outdated marine charts discover obstacles during installation-when mobilizing vessels costs $300,000 per day and crews sit idle waiting for route changes. Geotechnical data gaps create the worst problems. A cable routed through what appears to be uniform sand encounters unexpected clay layers or rocky outcrops that require different burial equipment entirely. Installation crews then deploy hybrid burial systems that weren’t planned for or attempt workarounds that compromise cable protection. The Olympic Coast National Marine Sanctuary experienced this in 2005 when improper burial depth led to cable exposure and required expensive remediation afterward.

Comprehensive geotechnical surveys covering the entire planned route prevent these failures. These surveys reveal sediment composition, bearing capacity, and potential obstacles that determine which burial method actually works. Regulatory approvals demand this data-NOAA and USACE won’t issue permits without evidence that you understand what you’re installing into.

Permitting Requires Early Coordination

Starting permitting conversations after design is final guarantees redesigns and delays. Early coordination with all relevant agencies prevents discovering halfway through that your preferred route crosses critical Essential Fish Habitat or a National Marine Sanctuary boundary where burial methods face restrictions. Regulatory bodies scrutinize every routing decision, and the approval process spans multiple federal agencies, each enforcing different rules. NOAA handles National Marine Sanctuaries, BOEM regulates cables on the Outer Continental Shelf, USACE reviews environmental impacts, and the FCC issues Cable Landing Licenses. This complexity means you should initiate permitting discussions before finalizing your design.

Burial depth errors Cause Long-Term Failures

Burial depth errors cause more long-term failures than any other single factor. Cables buried too shallow face damage from fishing trawls and ship anchors within the first few years of operation. Cables buried too deep waste money and disrupt more seabed habitat than necessary. Cable burial is the primary method of cable protection in water depths less than 1,000 meters. Deep water installations exceeding 2,000 meters often skip burial entirely since fishing activity and anchor drops don’t reach the seabed at those depths, yet some projects still attempt burial that adds cost without benefit.

Environmental Factors and Seasonal Restrictions

Environmental factors demand equal attention to technical specifications. Seasonal restrictions protecting spawning fish and marine mammals aren’t bureaucratic obstacles-they exist because installation vessels create noise and seabed disturbance during critical breeding windows. Scheduling work outside these windows prevents permit denials and demonstrates regulatory compliance. Installation is the most environmentally sensitive phase due to seabed disturbance and increased vessel activity, so timing your work correctly prevents costly delays and violations.

Future Maintenance Access Determines Long-Term Costs

Future maintenance access gets overlooked entirely by teams focused on initial installation. Cables crossing shipping lanes or positioned in areas where repair vessels can’t safely approach create situations where damage becomes catastrophic. A cable that takes three weeks to repair in accessible water might take three months in remote locations where weather windows narrow and specialized vessel availability shrinks. Route planning must account for future repair scenarios, not just initial installation logistics. Shortest routes cost less initially but often create maintenance nightmares that compound costs over decades (weather delays, limited repair vessel access, extended downtime). The best feasible underwater cable solution balances route choice, environmental impact, marine traffic, cost, and project timing-not just the installation phase alone.

Final Thoughts

Underwater cable installation succeeds when planning, execution, and long-term oversight align perfectly. Projects that stay on schedule and within budget invest heavily in site surveys and geotechnical analysis before mobilizing vessels, coordinate with regulators from day one rather than scrambling for permits after design is locked, and select burial depths based on actual seabed conditions and risk exposure rather than guesswork. These decisions compound over time-a cable routed through properly surveyed territory with correct burial depth and appropriate vessel selection operates reliably for decades, while a cable installed without this foundation faces expensive repairs, extended downtime, and regulatory complications that dwarf any initial savings.

Professional execution matters because submarine cable installation operates at scales most infrastructure projects never reach. Vessel mobilization costs hundreds of thousands daily, crews require specialized training in deep-sea operations, and environmental conditions create narrow windows for work. Teams that understand seabed geology, vessel dynamics, and regulatory requirements navigate these constraints effectively, while teams that lack this expertise discover problems when solutions become exponentially more expensive.

Long-term maintenance and monitoring determine whether your investment delivers value across the cable’s thirty-year lifespan. Post-lay inspection verifies burial depth and cable placement, but ongoing monitoring catches emerging threats before they cause failures. Clouddle provides cutting-edge technology solutions that keep your operations running smoothly, applying the same attention to detail that makes underwater cable installation successful to every infrastructure decision you make.