Construction companies lose $1.85 trillion annually due to poor technology adoption, according to McKinsey research. Most firms still rely on outdated systems that create communication gaps and project delays.

We at Clouddle see how the right IT solutions for construction industry can transform operations. Modern technology reduces project costs by 15% while improving delivery times by 25%.

Why Construction Projects Fail Before They Start

Construction teams waste 14 hours per week searching for project information across disconnected systems. Poor data management and miscommunication between field crews and office staff contribute to roughly $31 billion of rework per year in the U.S. Project managers spend 40% of their time on administrative tasks instead of actual construction oversight.

Communication Breakdowns Cost Real Money

Field teams that use outdated radio systems and paper-based processes create information silos that delay decision-making. Superintendents who cannot access real-time project updates cause change orders to take 3-5 days longer to process. Construction firms report that poor communication between architects, contractors, and subcontractors increases project costs by 8-12% on average. Teams that work across multiple job sites struggle to maintain consistent information flow, which leads to duplicated work and missed deadlines.

Document Chaos Multiplies Project Risks

Construction projects generate over 2.5 billion documents annually, with 90% stored in incompatible formats across different systems. Version control failures cause teams to work from outdated blueprints, which results in costly rework that averages $31,000 per incident (according to Dodge Construction Network data). Paper-based document management creates compliance nightmares when safety inspectors request specific certifications or when legal disputes require complete project documentation trails.

Equipment Vanishes Without Digital Oversight

Construction companies lose $400 billion worth of equipment annually through theft, misplacement, and poor systems. Manual equipment logs fail to capture real-time location data, which causes project delays when critical machinery goes missing. Maintenance schedules based on spreadsheets result in 23% more equipment breakdowns compared to automated systems. Without IoT sensors and digital asset management, construction firms cannot optimize equipment utilization rates that average only 35% across the industry.

These fundamental technology gaps create a domino effect that impacts every aspect of construction operations. Modern IT solutions address these core problems through integrated platforms that connect field teams, streamline document workflows, and provide real-time asset visibility.

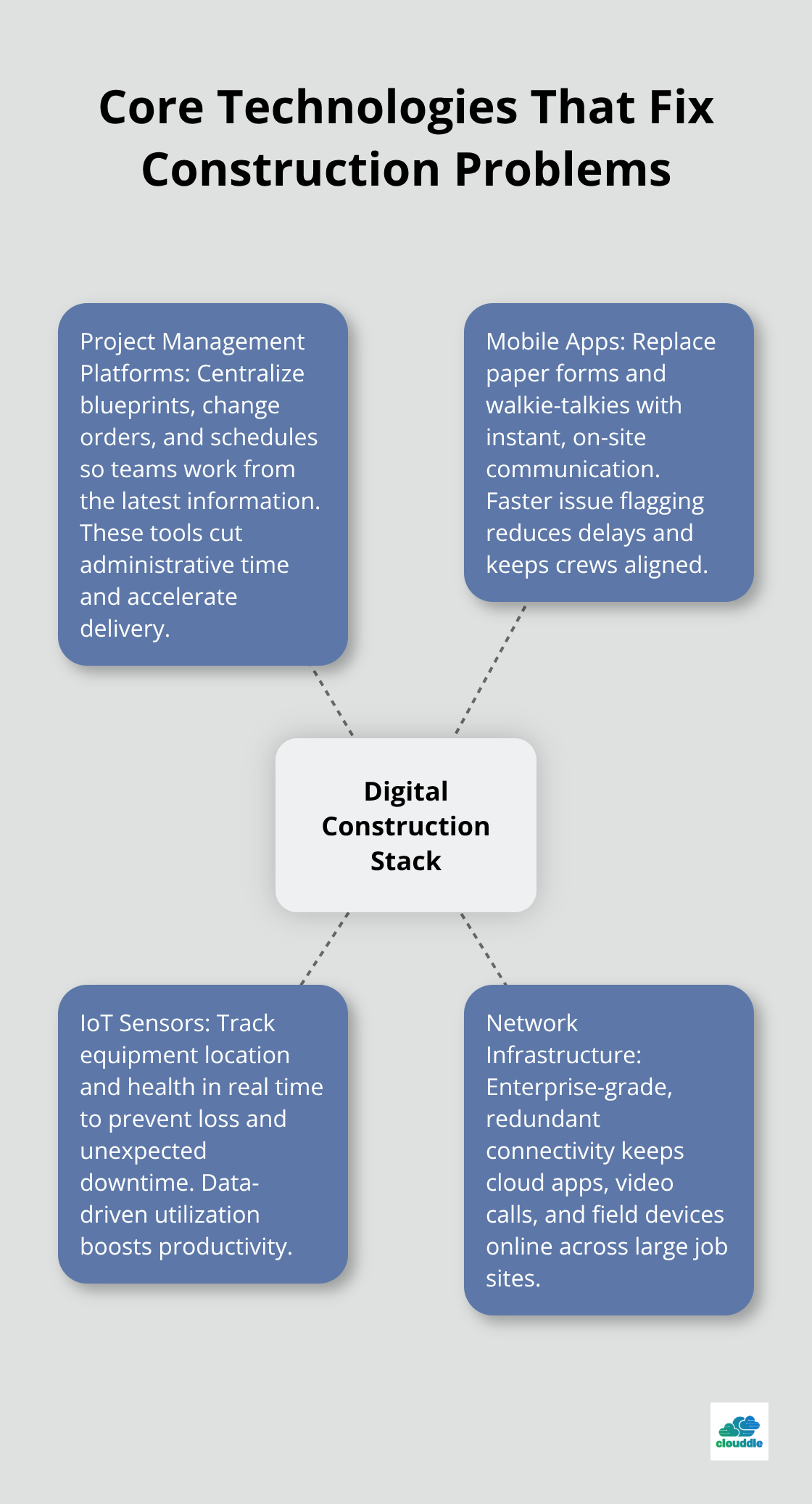

What Technology Actually Fixes Construction Problems

Cloud-based project management platforms eliminate the document chaos that costs construction firms significant rework expenses. Procore and Autodesk Construction Cloud connect field teams with real-time access to blueprints, change orders, and project schedules from any device. These systems reduce administrative time by 40% because superintendents approve changes instantly instead of waiting for paper workflows. Construction companies that use integrated platforms report 25% faster project delivery times because teams access current information without searching through email chains or outdated file servers.

Mobile Apps Transform Field Operations

Smartphone apps designed for construction sites replace walkie-talkies and paper forms with instant communication tools. PlanGrid allows field crews to mark up blueprints and send updates directly to project managers within minutes. Workers equipped with ruggedized tablets photograph progress, report safety issues, and access technical specifications without returning to the trailer office. Companies that deploy mobile-first communication systems see 30% fewer project delays because problems get flagged and resolved immediately rather than during weekly meetings.

Smart Sensors Stop Equipment Loss

IoT tracking devices attached to construction equipment provide GPS location data and usage analytics that prevent substantial losses from theft and misplacement. Construction equipment theft alone accounts for annual losses ranging from $300 million to $1 billion in the United States. Caterpillar Connect and John Deere WorkSight monitor machine hours, fuel consumption, and maintenance needs automatically. These systems send alerts when equipment leaves designated job sites or requires service (which reduces unexpected breakdowns by 23% compared to manual maintenance schedules). Construction firms that use IoT sensors achieve 60% better equipment utilization rates because managers locate and deploy machinery based on real-time availability data rather than guesswork.

Network Infrastructure Powers Digital Construction

Reliable internet connectivity forms the backbone that supports all digital construction tools. Construction sites require robust Wi-Fi networks to handle multiple devices, video calls, and cloud-based applications simultaneously. Poor network performance causes mobile apps to crash and prevents real-time data synchronization between field teams and office staff. Companies invest in enterprise-grade networking solutions (including redundant internet connections and mesh Wi-Fi systems) to maintain consistent connectivity across large job sites.

The right technology stack addresses core construction challenges, but successful implementation requires careful planning and strategic vendor selection to maximize these digital investments.

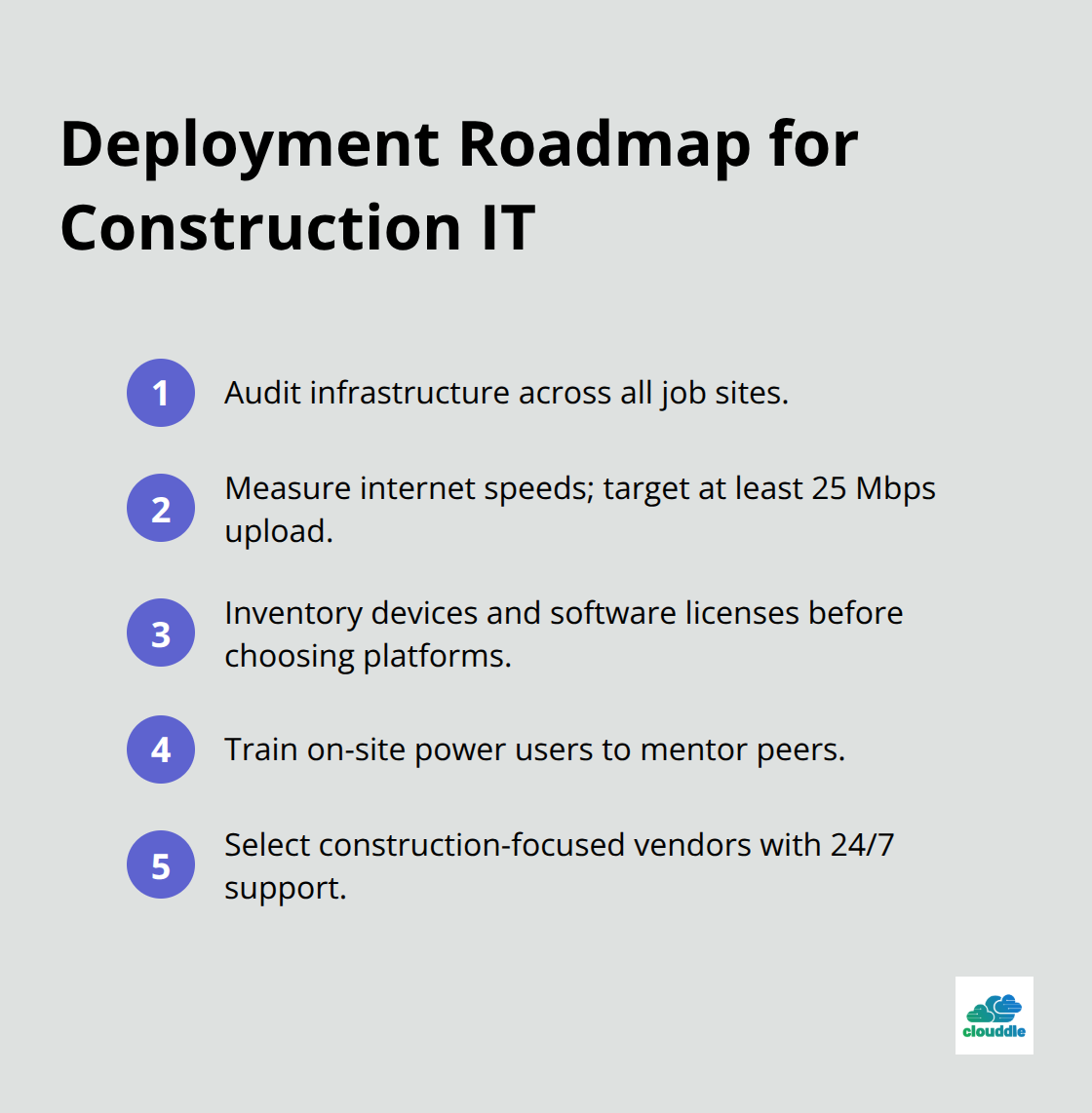

How to Deploy Construction IT Successfully

Construction firms that skip infrastructure audits waste significant resources on technology implementations that fail within 18 months. Start with a comprehensive assessment of your current network capacity, device inventory, and software licenses across all job sites. Document internet speeds at each location because cloud-based construction platforms require minimum 25 Mbps upload speeds for real-time collaboration. Catalog existing hardware (tablets, smartphones, and computers) to determine upgrade needs before you select new software platforms.

Construction companies that conduct thorough infrastructure audits reduce implementation costs and avoid compatibility issues that derail digital transformation projects.

Staff Training Determines Technology Success

Construction workers resist new technology when training programs ignore their daily workflows and job site realities. Effective training starts with power users who champion new tools and can mentor resistant team members during the transition period. Companies that provide hands-on training sessions directly on job sites see faster adoption rates compared to classroom-style instruction. Focus training on specific tasks workers perform daily rather than comprehensive software overviews that overwhelm users. Construction firms with structured change management programs achieve better ROI from technology investments because workers actually use the new systems consistently.

Choose Vendors Who Understand Construction

Generic IT providers fail construction companies because they lack industry-specific experience with job site challenges and regulatory requirements. Select vendors who demonstrate proven experience with construction clients and offer 24/7 support for field operations that run outside normal business hours. Evaluate potential partners based on their ability to integrate with existing construction software like Procore, PlanGrid, or AutoCAD rather than force you to replace functional systems. Construction-focused IT providers offer ruggedized hardware options, understand OSHA compliance requirements, and provide mobile device management solutions designed for harsh job site environments (which generic providers often overlook).

Final Thoughts

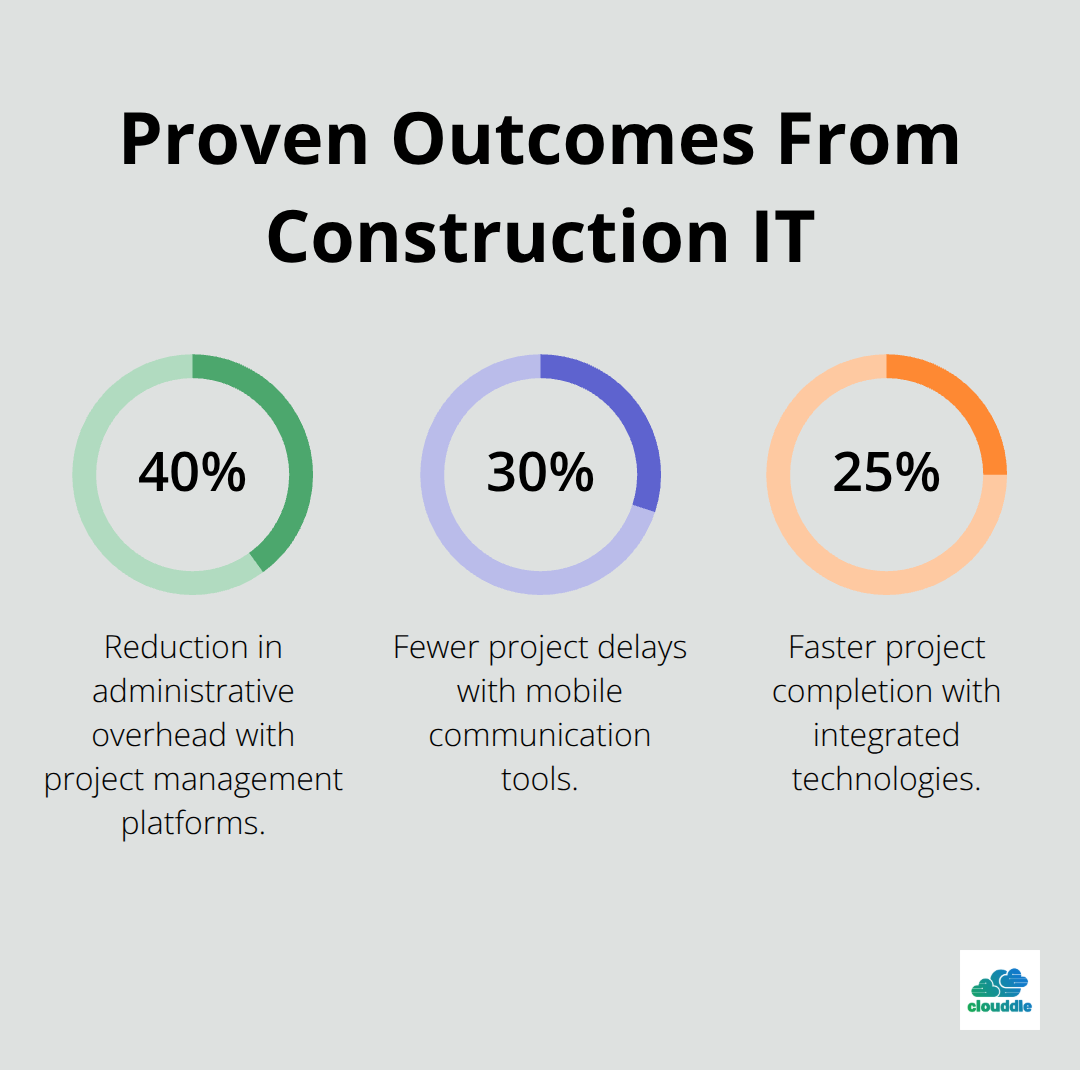

Construction companies that implement comprehensive IT solutions for construction industry see measurable returns within 12-18 months. Project management platforms reduce administrative overhead by 40%, while mobile communication tools cut project delays by 30%. IoT equipment tracking prevents the $400 billion in annual losses from theft and misplacement, and these technologies combined deliver 15% cost reductions and 25% faster project completion times.

The financial impact extends beyond immediate savings. Construction firms with modern IT infrastructure win more contracts because they demonstrate operational efficiency and real-time project visibility to clients. Digital transformation also attracts younger workers who expect technology-enabled workplaces (which addresses the industry’s critical labor shortage).

Success requires strategic implementation that starts with infrastructure assessment, comprehensive staff training, and selection of construction-focused vendors. We at Clouddle understand construction’s unique technology challenges and provide managed IT services with 24/7 support, network solutions, and security services designed for demanding job site environments. Construction companies can focus on their projects while we handle the technology infrastructure that powers modern operations.