Manufacturing companies face mounting pressure to modernize their technology infrastructure. Legacy systems, cybersecurity risks, and integration challenges threaten operational efficiency across the industry.

We at Clouddle see how the right IT solutions for manufacturing industry can transform production capabilities. Smart technology implementations drive measurable improvements in quality control, cost reduction, and supply chain management.

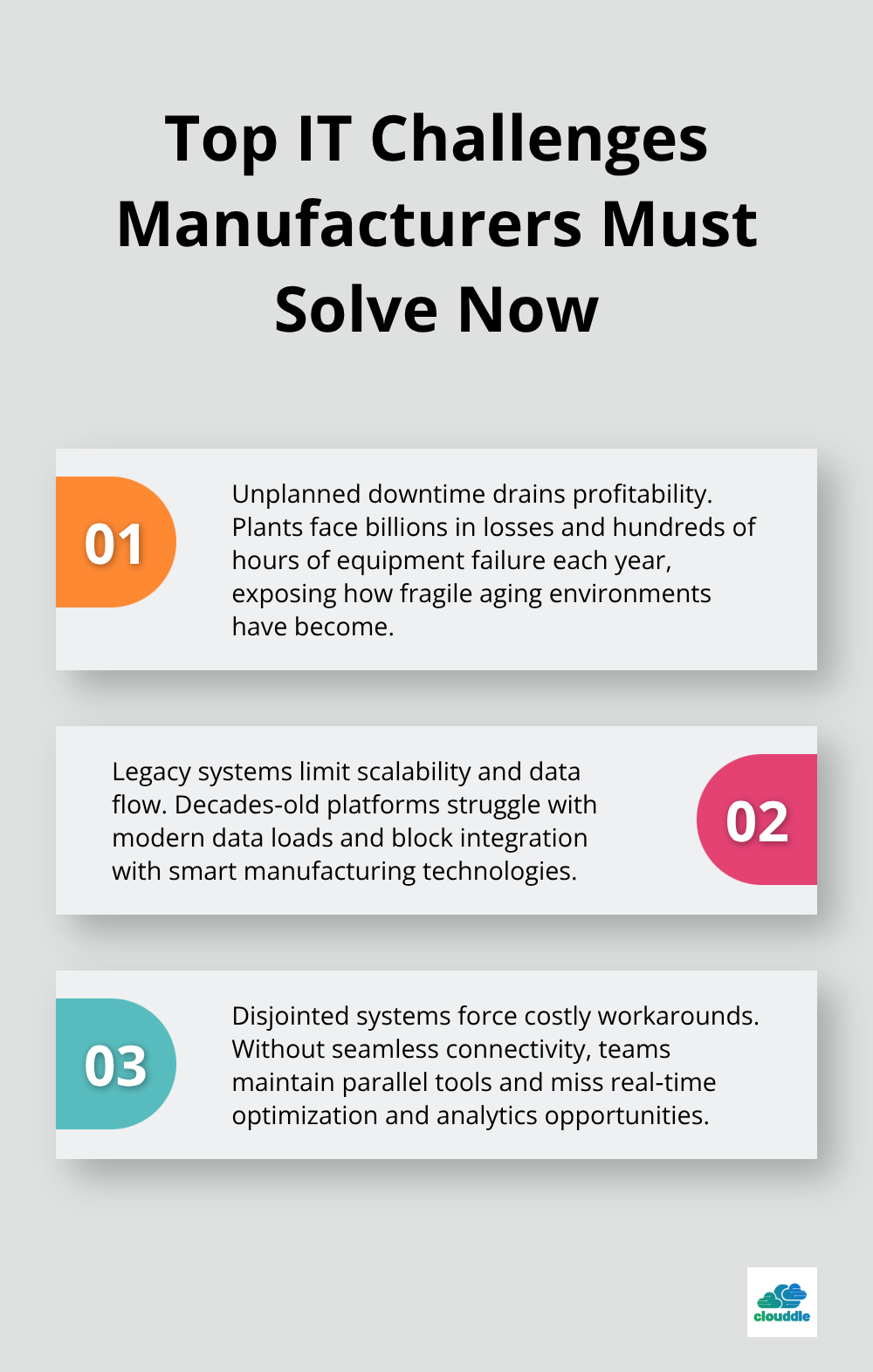

Key IT Challenges in Modern Manufacturing

Manufacturing companies lose approximately $50 billion annually due to unplanned downtime, with the average facility experiencing over 800 hours of equipment failure each year according to industry studies. Legacy systems built decades ago cannot handle modern data loads or integrate with smart manufacturing technologies. These outdated infrastructures force manufacturers to maintain expensive parallel systems while they miss opportunities for real-time optimization and predictive analytics.

Cybersecurity Attacks Target Manufacturing Operations

Ransomware attacks against the manufacturing sector surged from 520 incidents to 838, marking a 61% increase, making the sector a prime target for ransomware and data theft. Manufacturing networks often lack proper segmentation between operational technology and business systems, which creates vulnerabilities that can shut down entire production lines. Companies with weak cybersecurity concerns face average recovery costs that exceed $4 million per incident (not including lost production time and damaged customer relationships).

System Integration Failures Block Digital Transformation

Most manufacturing facilities operate with disconnected systems that cannot share data effectively, which prevents the implementation of Industry 4.0 technologies. When operational technology systems like SCADA and PLCs cannot communicate with enterprise software, manufacturers lose visibility into real-time production metrics and quality control data. This fragmentation costs companies up to 10% of their available production time through inefficient processes and manual data transfers that automation should handle.

These fundamental IT challenges create a cascade of operational problems that modern technology solutions can address. The next step involves understanding which specific IT solutions deliver the greatest impact on manufacturing performance.

Essential IT Solutions for Manufacturing Operations

Cloud Computing Transforms Data Management

Manufacturing companies that deploy cloud-based data management systems cut equipment downtime through reduced incident frequency according to recent industry analysis. Cloud platforms process the massive data volumes from modern production lines while they deliver real-time analytics that legacy systems cannot handle. General Electric saves millions annually through cloud-based predictive maintenance systems that analyze equipment performance data from thousands of sensors. These platforms scale automatically during peak production periods and connect seamlessly with existing manufacturing execution systems.

Industrial IoT Sensors Generate Actionable Intelligence

Industrial Internet of Things sensors create over 2.5 quintillion bytes of data daily, but only companies with proper data management systems transform this information into actionable insights. Smart sensors track everything from vibration patterns in rotating equipment to temperature variations in chemical processes (feeding data directly into enterprise resource planning systems for immediate response). Manufacturing facilities that use integrated IoT and ERP platforms achieve improved supply chain visibility according to industry reports.

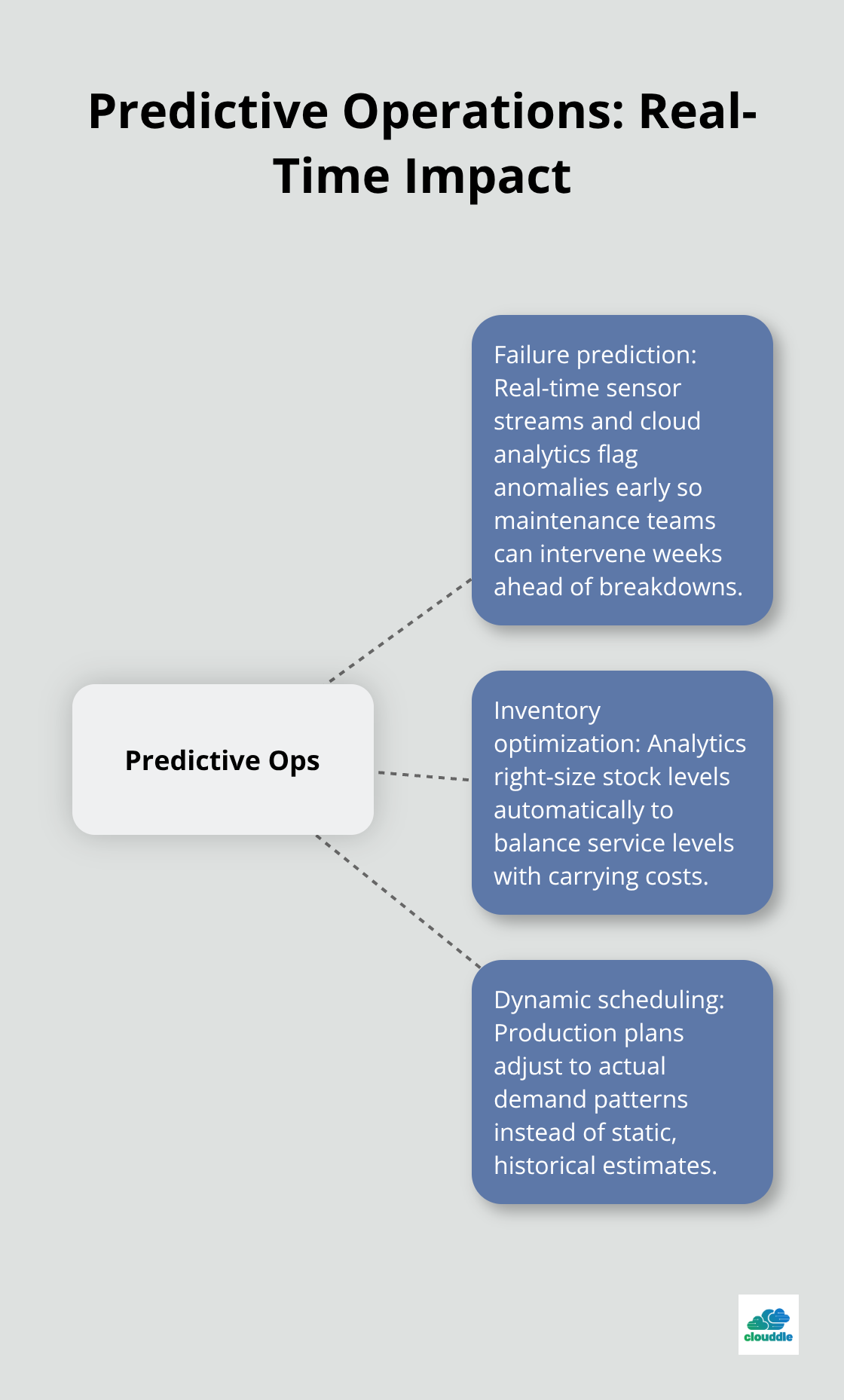

Real-Time Analytics Enable Predictive Operations

The combination of real-time sensor data with cloud-based analytics allows manufacturers to predict equipment failures weeks before they occur. These systems optimize inventory levels automatically and adjust production schedules based on actual demand patterns rather than historical estimates.

Companies report significant cost savings when they reduce operational costs by replacing reactive maintenance approaches with predictive models that analyze equipment performance continuously.

Advanced manufacturing execution systems now integrate with these technologies to create comprehensive operational visibility that extends beyond individual production lines to entire supply chain networks.

Benefits of Advanced IT Solutions for Manufacturing

Manufacturing companies that implement comprehensive IT solutions experience significant operational improvements, as Deloitte research shows that factories and operations are getting smarter while manufacturers work to overcome obstacles in talent acquisition. These advanced systems deliver substantial benefits through reduced downtime, optimized energy consumption, and streamlined production workflows. Companies that use predictive maintenance systems cut unplanned equipment failures by up to 70%, while real-time quality control systems reduce defect rates by 30-50%. These improvements translate directly to bottom-line results through lower labor costs, reduced waste, and faster time-to-market for new products.

Predictive Analytics Cut Maintenance Expenses

Manufacturers that use AI-powered predictive maintenance save 12-18% on maintenance costs while they extend equipment lifespan by 20-40% according to McKinsey analysis. These systems analyze vibration patterns, temperature fluctuations, and performance metrics to schedule maintenance precisely when needed rather than follow fixed intervals. Siemens reports that their predictive maintenance programs prevent 95% of potential equipment failures before they occur. The technology eliminates unnecessary maintenance activities while it prevents catastrophic breakdowns that can cost hundreds of thousands in lost production time.

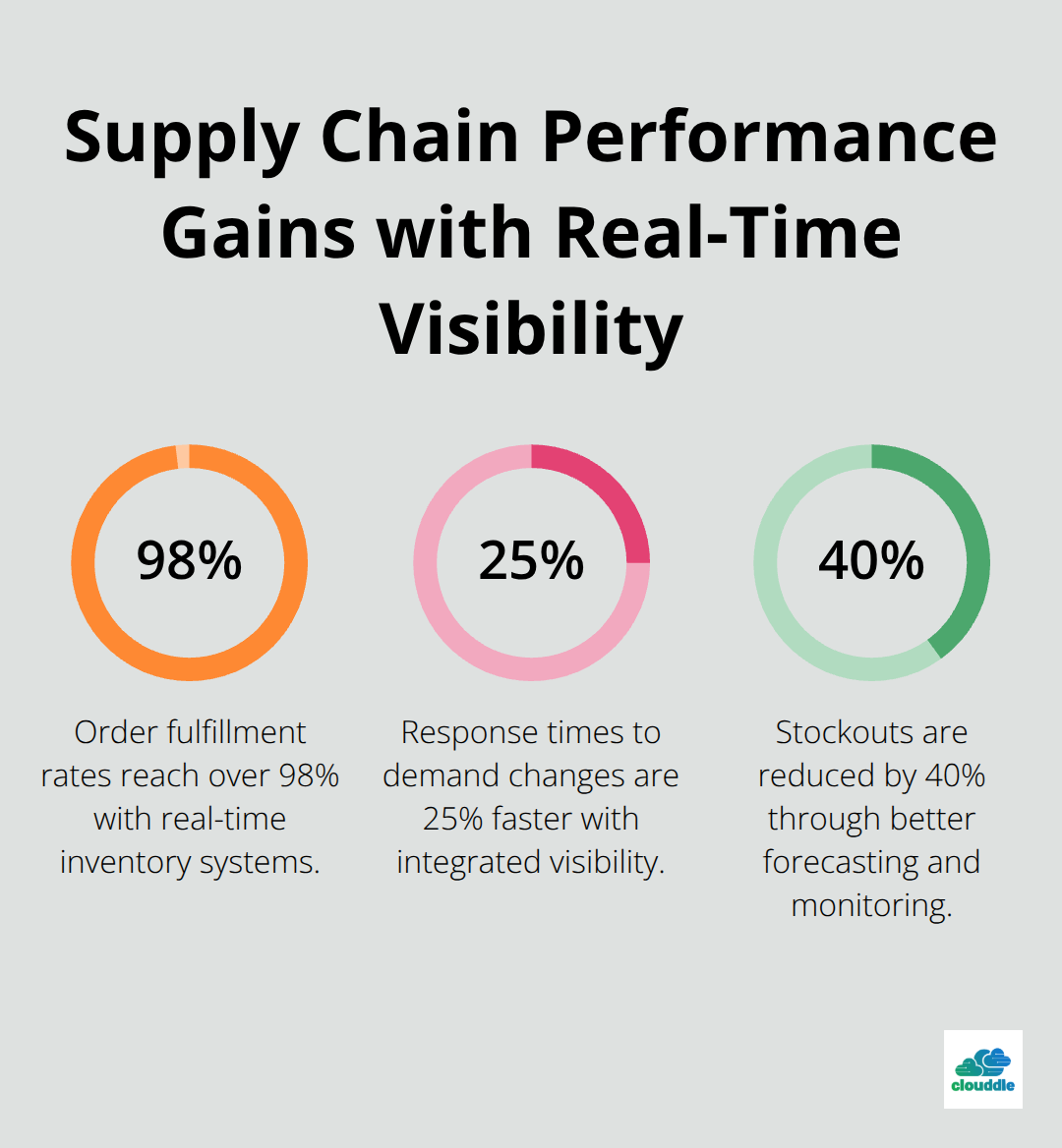

Real-Time Supply Chain Visibility Accelerates Decision Speed

Advanced analytics platforms process supply chain data in milliseconds, which enables manufacturers to respond to disruptions 5-10 times faster than companies that use traditional systems. Real-time inventory systems reduce carrying costs by 20-30% while they improve order fulfillment rates to over 98%. Companies with integrated supply chain visibility report 25% faster response times to customer demand changes and 40% reduction in stockouts (with machine learning algorithms that become more accurate at demand prediction over time).

Quality Control Systems Reduce Production Defects

Automated quality control systems that integrate with production lines detect defects 10 times faster than manual inspection processes. These systems use computer vision and sensor data to identify quality issues in real-time, which prevents defective products from reaching customers. Manufacturing facilities report defect reduction rates of 30-50% within six months of implementation, while they achieve consistent quality standards across multiple production shifts and locations. Managed IT services help manufacturers implement and maintain these advanced systems effectively, while operational cost reduction strategies ensure maximum return on technology investments.

Final Thoughts

Manufacturing companies that adopt comprehensive IT solutions for manufacturing industry achieve measurable competitive advantages through reduced downtime, improved quality control, and optimized supply chain operations. The data reveals clear returns on investment: predictive maintenance cuts costs by 12-18%, real-time analytics reduce defects by 30-50%, and integrated systems deliver 25% faster response times to market changes. These improvements create immediate operational benefits that strengthen bottom-line performance.

Modern IT infrastructure enables companies to adapt faster to market disruptions, scale production more efficiently, and maintain higher customer satisfaction rates. These advantages compound over time as competitors struggle with legacy system limitations. Smart manufacturers position themselves for sustained growth through technology investments that transform operational capabilities.

Manufacturing IT modernization requires strategic planning and expert implementation (with proper security measures and integration protocols). We at Clouddle help manufacturers navigate this transformation through comprehensive managed services that support technology infrastructure needs. The combination of cloud computing, IoT sensors, and predictive analytics creates the foundation for manufacturing excellence in an increasingly competitive global market.