When you're weighing predictive maintenance vs preventive maintenance, it boils down to one key distinction. Preventive maintenance is time-based, like your car's scheduled oil change. Predictive maintenance is condition-based, like replacing your tires when the tread gets low, not just because you've driven 30,000 miles.

Preventive work follows a strict calendar, regardless of how an asset is actually performing. Predictive work, on the other hand, is only triggered when real-world data points to a problem on the horizon.

Understanding the Core Maintenance Philosophies

Choosing a maintenance strategy isn't just about picking a schedule. It’s a business philosophy that directly hits your budget, your team's efficiency, and in the hospitality world, even your guest satisfaction scores. Your choice determines where your technicians spend their time and how well you can dodge those disruptive, middle-of-the-night equipment failures.

At its core, the debate is between a traditional, by-the-book approach and a modern, data-driven one. Both are designed to get ahead of catastrophic breakdowns, which is a massive leap from just fixing things after they break. If you're new to this, our guide on proactive maintenance vs reactive maintenance is a great starting point. But for truly optimizing a commercial property, understanding the subtle yet powerful differences between preventive and predictive is essential.

The Foundation of Each Approach

For decades, preventive maintenance has been the industry standard. It runs on a simple, predictable principle: service equipment at regular intervals. Think of it as servicing your HVAC unit every six months or inspecting elevator cables annually, whether they look frayed or not. The biggest plus here is its simplicity and how easy it is to schedule.

Predictive maintenance is the smarter evolution of this idea. It uses technology—IoT sensors, monitoring platforms—to get a live look at how equipment is actually doing. Instead of relying on manufacturer averages to guess when a part might fail, it analyzes real-time data like vibration patterns, temperature fluctuations, and energy use to forecast problems with stunning accuracy. This means you can perform maintenance right when it's needed, getting the most life out of your assets and using your team's time effectively.

Key Takeaway: Preventive maintenance asks, "When did we last service this?" Predictive maintenance asks, "What's the real-time health of this asset telling us right now?"

The table below lays out these core differences, giving a clear picture of how they impact operations and your bottom line.

| Aspect | Preventive Maintenance (Time-Based) | Predictive Maintenance (Condition-Based) |

|---|---|---|

| Trigger | A fixed calendar or usage meter (e.g., every 6 months). | Real-time data and analytics (e.g., an unusual temperature spike). |

| Core Goal | Lower the probability of failure with routine upkeep. | Predict and prevent failures by monitoring actual equipment condition. |

| Data Reliance | Manufacturer recommendations and historical averages. | Live operational data, AI, and machine learning models. |

| Typical Use Case | Less critical assets with predictable wear (e.g., air filters). | High-value, critical assets where downtime is a disaster (e.g., central chillers). |

A Detailed Comparison of Maintenance Approaches

Once you get past the textbook definitions, you need to see how these maintenance philosophies actually stack up in the real world. When you put predictive maintenance vs preventive maintenance side-by-side, the differences in core operational areas become incredibly clear. These distinctions ripple out, affecting everything from a technician's daily schedule to your facility's long-term financial health.

To really grasp the trade-offs, we need to look at their foundational strategies, how the money flows, the demands on your team, and the way each one tackles risk. By framing this with examples from commercial properties and hotels, the comparison becomes much more tangible for anyone making these calls on the ground.

Core Strategy and Execution

The fundamental strategy is where these two paths diverge most sharply. Preventive maintenance runs on a strict, time-based schedule. You perform tasks at set intervals, whether the equipment seems to need it or not.

Think of a hotel's HVAC system. Under a preventive plan, you might replace the air filters every three months, period. It's straightforward and easy to plan for, but it often means you're doing unnecessary work—like swapping out a filter that could have lasted another month.

Predictive maintenance, on the other hand, is all about condition. It uses real-time data from sensors and monitoring platforms to tell you when a piece of equipment actually needs attention.

Now, imagine that same HVAC system is fitted with sensors tracking airflow and pressure. Instead of a calendar reminder, your team gets an alert only when the data proves the filter is clogged and performance is dropping. This simple shift optimizes both your team’s time and your material costs.

Key Differentiator: Preventive maintenance is about preventing wear through routine checks. Predictive maintenance is about averting failure by listening to what the equipment is telling you right now.

Financial Structure and Investment

The financial models behind these strategies couldn't be more different. Preventive maintenance is built on predictable, recurring operational expenses (OpEx). You budget for routine labor, replacement parts, and lubricants based on a calendar. The upfront cost is low, making it a very accessible starting point for many organizations.

Predictive maintenance demands a significant upfront capital investment (CapEx). This isn't just a small line item; it's a project that includes costs for:

- IoT Sensors: Devices that measure vibration, temperature, power consumption, and other critical health indicators.

- Monitoring Platforms: The software backbone needed to collect, analyze, and make sense of all that incoming data.

- Network Infrastructure: A robust and secure network is absolutely non-negotiable for transmitting sensor data reliably.

While the initial sticker shock can be high, the entire point is to drive down total maintenance spending by 25-35% over the long run by cutting out wasted effort and preventing catastrophic, budget-breaking failures.

Resource Management and Labor Allocation

How you manage your people also changes dramatically. Preventive maintenance works with planned labor. Technicians follow a set schedule, which makes it simple to allocate resources and forecast workloads for the coming weeks and months. For a deeper look at this, our guide on preventive maintenance best practices breaks down how to structure these schedules effectively.

Predictive maintenance flips the script to on-demand, highly targeted work. Your technicians are dispatched based on data-driven alerts, not a to-do list tied to the calendar. This requires a more agile team that can respond to specific, data-identified problems. For example, instead of inspecting every elevator motor each quarter, a team is sent to service a specific motor only after vibration analysis flags a bearing that’s starting to fail.

Risk Mitigation Approach

Finally, let's talk about how each strategy handles risk. Preventive maintenance aims to lower the overall probability of failure across an asset's lifespan through regular upkeep. It’s a broad-strokes approach that's effective for equipment with fairly predictable failure patterns, like replacing the belts on an industrial kitchen's exhaust fan before they have a chance to snap.

Predictive maintenance offers a much more precise way to mitigate risk. By monitoring the actual, real-time condition of your most critical assets, it can spot subtle signs of trouble long before they become full-blown emergencies. This is absolutely essential for high-value equipment where downtime is a disaster—think a commercial building's main electrical switchgear or a resort's central boiler. This strategy doesn't just reduce the probability of failure; it actively averts it using specific, actionable intelligence.

To make these differences even clearer, let's distill them into a quick-reference table.

Predictive Vs Preventive Maintenance Key Differentiators

This table summarizes the core differences between the two maintenance philosophies, giving you an at-a-glance view of how they compare across key operational criteria.

| Criterion | Preventive Maintenance (Time-Based) | Predictive Maintenance (Condition-Based) |

|---|---|---|

| Trigger | Fixed schedule (e.g., every 3 months) | Real-time asset condition data (e.g., high vibration) |

| Strategy | Proactive, scheduled upkeep to prevent wear | Data-driven intervention to avert failure |

| Cost Model | Low initial CapEx, predictable ongoing OpEx | High initial CapEx, lower long-term OpEx |

| Labor | Planned, scheduled tasks | On-demand, data-triggered responses |

| Efficiency | Can lead to unnecessary maintenance and costs | Maximizes asset life and minimizes wasted labor |

| Risk Focus | Reduces general probability of failure | Precisely identifies and averts specific failures |

| Best For | Assets with predictable failure modes; lower cost | Critical, high-value assets where downtime is costly |

As you can see, the choice isn't just about scheduling—it's about fundamentally different approaches to cost, labor, and risk management. One focuses on disciplined routine, while the other relies on intelligent, data-backed intervention.

Analyzing the Financial Impact and ROI

When you're weighing predictive maintenance vs. preventive maintenance, the conversation always comes back to money. The two strategies couldn't be more different in how they impact your finances, from your yearly budget structure all the way to your long-term return on investment (ROI). Getting a firm grip on these financial dynamics is critical to making a smart decision for your property.

Preventive maintenance is all about predictable, recurring operational expenses (OpEx). You budget for labor, parts, and supplies on a fixed, calendar-based schedule. This makes financial planning pretty simple, since your expenses stay mostly flat from quarter to quarter. The barrier to entry is low.

Predictive maintenance completely flips that model. It demands a significant upfront capital expenditure (CapEx) for the technology. This initial spend covers things like IoT sensors, data analytics software, and the powerful network infrastructure needed to make it all work. While that initial hit is higher, the long-term play is to slash your total operational spending by cutting out unnecessary work and, more importantly, preventing those catastrophic failures that drain your budget.

Breaking Down the Total Cost of Ownership

To really see the full picture, you have to look past the initial price tag and consider the total cost of ownership (TCO) for each approach.

Preventive Maintenance TCO includes:

- Scheduled Labor: Paying technicians to perform routine checks and tasks, whether the equipment needs it or not.

- Routine Parts Replacement: Budgeting for parts that get swapped out on a schedule, even if they still have plenty of life left in them.

- Unexpected Downtime: This is the big one—the hidden, often massive, cost of emergency repairs when a system fails between those scheduled check-ins.

Predictive Maintenance TCO includes:

- Initial Technology Investment: The upfront CapEx for sensors, software platforms, and getting the network set up.

- Targeted Labor: Technicians only respond to data-driven alerts, so you’re not paying for wasted time and effort.

- Optimized Parts Usage: You replace parts based on their actual condition, which means you squeeze every bit of value out of them and cut down on inventory waste.

Sure, the upfront cost for a predictive system can feel steep, but the financial payoff comes from using your resources with surgical precision. That’s an advantage a simple scheduled routine can never offer.

Calculating the Return on Investment

The core financial argument for predictive maintenance is its powerful long-term ROI. The data from the field is pretty clear: while the initial investment might be 3 to 4 times higher than a basic preventive program, the ongoing savings are huge. Predictive programs have been shown to cut unplanned downtime by 50–65% and extend the life of your assets by 20–40% compared to just following the calendar.

This ultimately leads to an estimated 25–35% greater cost reduction over time because you’re only performing maintenance exactly when it’s needed. For a deeper dive, check out the impressive results from Shell's C3 AI Predictive Maintenance case study, where they managed to cut downtime by a full 20%. Stories like that really highlight the tangible wins you get from a data-driven strategy.

Crucial Insight: The ROI from predictive maintenance isn't just about saving a few bucks on parts. It's about dodging the massive costs of operational disruption—think lost revenue from an entire hotel floor being out of service due to an HVAC failure, or the sky-high emergency fees to repair a critical electrical panel on a weekend.

At the end of the day, the financial debate between predictive and preventive maintenance comes down to a classic trade-off. Preventive offers lower initial costs and simple budgeting. Predictive, on the other hand, requires a serious upfront investment but delivers far greater long-term efficiency, less downtime, and a much healthier ROI on your most important assets.

How to Choose the Right Strategy for Your Assets

When it comes to maintenance, the debate between predictive and preventive isn’t an either/or dilemma. Honestly, picking just one is a mistake. The smartest, most cost-effective approach for commercial properties and hotels is to build a balanced, hybrid strategy. There’s simply no single answer that fits every pump, fan, and chiller in your facility.

The real key is to apply the right strategy to the right asset. You have to weigh its importance, the ripple effect of its failure, and whether you can even get useful data from it. This blended model lets you focus resource-heavy predictive tech on your mission-critical systems while keeping efficient, routine schedules for everything else. It's all about maximizing ROI.

Conducting an Asset Criticality Audit

Your first step is to figure out what really matters. An asset criticality audit is a formal way of categorizing your equipment to determine where your maintenance budget will do the most good. It’s about moving past a one-size-fits-all calendar and making informed decisions.

Start by mapping out every major piece of equipment. For each one, you need to ask three fundamental questions:

- What is the impact of failure? Is it a minor inconvenience, like a single guest room’s AC going down? Or is it a catastrophic shutdown, like the main electrical switchgear for the entire building failing?

- How predictable is the failure? Does this piece of equipment have known wear-and-tear patterns that a simple schedule can handle, like changing air filters? Or are failures more random and complex, demanding real-time monitoring to catch?

- Is condition data available and useful? Can you actually install sensors to gather meaningful data—vibration, temperature, power draw—that would accurately signal a pending failure?

Answering these questions creates a natural hierarchy, pointing you toward the most logical maintenance plan for each asset.

Strategic Insight: A hybrid model isn't a compromise; it's an optimization. It directs your most powerful maintenance tools—and your budget—to the assets where they will deliver the highest return by preventing the most damaging failures.

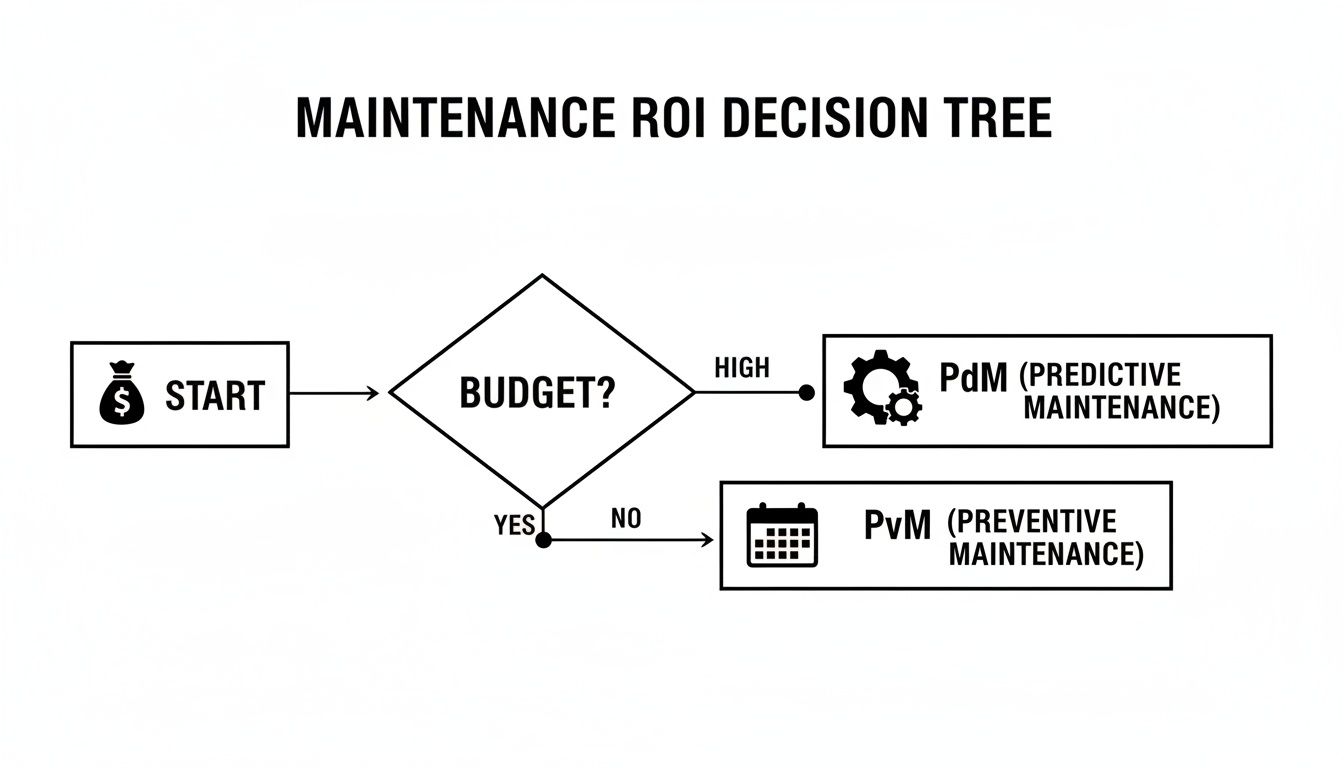

The decision tree below gives you a simple visual for how factors like budget and asset criticality should steer your choice.

As the flowchart shows, bigger budgets and more critical assets are a natural fit for predictive maintenance, while preventive schedules remain the practical, go-to choice for lower-risk equipment.

Building Your Blended Maintenance Program

With your audit complete, you can start matching strategies to assets. It’s no surprise that global studies on industrial IoT show a clear trend: companies put predictive maintenance on equipment whose failure would cause major operational losses, safety risks, or sky-high repair bills. Most organizations find a sweet spot by applying predictive monitoring to their top 10–30% of critical machines, while keeping the rest on a preventive schedule. You can read more about these strategic adoption patterns on ibm.com.

So, what does this look like in a real-world hotel or commercial building?

Assets for Predictive Maintenance (High-Impact, High-Value):

- Central Chillers and Boilers: These are the heart of your property’s HVAC. If they go down, the entire building is affected, leading to massive revenue loss and a flood of guest complaints.

- Main Electrical Panels and Transformers: A failure here is a property-wide disaster. It’s a serious safety risk that brings all operations to a screeching halt.

- Elevator Motors and Systems: An out-of-service elevator creates huge accessibility problems and instantly damages the property’s reputation for quality and safety.

Assets for Preventive Maintenance (Lower-Impact, Predictable Wear):

- Secondary Water Pumps: While important, a failing secondary pump can often be covered by a backup, making scheduled check-ups perfectly adequate.

- Guest Room PTAC Units: A failure here only impacts one room, and these units can typically be swapped out in minutes. A simple, regular schedule for cleaning filters and coils is all you need.

- General Building Lighting: It’s far more cost-effective to schedule bulk bulb replacements and fixture inspections than it is to put a sensor on every light.

By putting this kind of blended strategy in place, you create a dynamic and efficient maintenance program. You stop over-servicing low-risk equipment and gain priceless insight into the health of your most critical assets. The result is optimized costs, reduced risk, and a seamless guest experience.

Putting Your Maintenance Plan into Action

Alright, so you’ve got the theory down. But how do you actually get a new maintenance program off the ground? Moving from a plan on paper to a real-world system requires a solid, step-by-step approach. Whether you’re tightening up a preventive schedule or jumping into a full predictive maintenance setup, the rollout is all about careful planning, choosing the right tools, and getting your team on board.

If you're going the preventive route, your first job is to build a comprehensive schedule. That means listing out every piece of equipment, digging up the manufacturer's service recommendations, and mapping out tasks for your crew. A good preventive maintenance schedule template can be a lifesaver here, giving you a strong framework to start from.

Getting a predictive maintenance program running, however, is a whole different ballgame. It's less about calendars and more about data and technology. You're essentially giving your assets a voice and learning to listen to what they're telling you.

Step 1: Start Small with a Pilot Program

Before you even think about buying a single sensor, look back at your asset audit. Pick a handful of your most critical, high-risk systems to be your test subjects. Don't try to boil the ocean.

Focusing on just 2-3 crucial assets—like the main HVAC chiller or the primary guest elevator—is the perfect way to start. It lets you prove the concept works and show a clear return on investment without breaking the bank on a massive initial rollout.

This targeted approach also makes it easier to get your team's buy-in. When they see the system flag a potential failure and prevent a major shutdown, you’ll build the confidence and momentum needed to expand the program across the entire property.

Step 2: Choose and Integrate Your Technology

Once you've picked your pilot assets, it's time to select the right tech. This isn’t just about buying gadgets; it's about building an integrated system where data flows smoothly from collection to action.

Your core technology stack will include:

- IoT Sensors: Pick sensors that track the right vitals for your pilot equipment. That might mean vibration sensors for motors, thermal cameras for electrical panels, or ultrasonic sensors to find hidden leaks.

- CMMS Platform: A modern Computerized Maintenance Management System (CMMS) is your command center. It needs to pull in sensor alerts, automatically generate work orders, and keep a detailed history of every repair. For a rundown of the best options, check out our guide to top software for building maintenance.

- Data Analytics Software: This is the brains of the operation. It sifts through all the incoming data, spots patterns that signal trouble, and turns that raw information into clear, actionable alerts for your technicians.

Step 3: Build a Rock-Solid Network Foundation

A predictive maintenance system is only as good as the network it runs on. You'll have dozens, maybe hundreds, of sensors constantly sending data. That requires a stable, secure, and fast network. If your network is shaky, you'll get dropped data, missed alerts, and a system you can't trust.

A Word of Caution: For most facility teams, managing a complex IoT network is a huge distraction. It's a specialized IT skill set that pulls you away from your actual job—keeping the building running. The network is absolutely critical, but it shouldn't be your headache.

This is where managed networking services come in. A partner like Clouddle can handle everything from designing and installing the network to managing it 24/7. We take the IT burden completely off your shoulders, ensuring you have the reliable, secure connectivity you need. This lets your team focus on what they're experts at—maintaining equipment, not wrestling with network problems.

Common Questions on Maintenance Strategies

When you start digging into predictive vs. preventive maintenance, a few key questions almost always come up. Facility managers and hospitality leaders I talk to are constantly trying to pin down the practical differences and figure out where to start. Getting straight answers is the only way to build a strategy that actually works for your property and your budget.

Let’s tackle some of the most common questions I hear. These are the things people ask when the theory is done and it's time to think about real-world implementation.

What’s the Real Difference Between Predictive and Preventive?

At its core, the distinction is simple: preventive maintenance runs on a calendar, while predictive maintenance runs on data.

Think of preventive maintenance like your car's oil change—you do it every 5,000 miles or six months, whether it really needs it or not. It's a scheduled, time-based routine.

Predictive maintenance is completely different. It uses sensors to monitor the actual condition of your equipment in real time. An alert only triggers when the data shows a genuine problem is starting to develop, like an unusual vibration in an HVAC motor. This means you act based on need, not just a date on the calendar.

Is a Hybrid Model Actually the Best Way to Go?

For nearly every commercial property or hotel I’ve seen, the answer is a firm yes. A hybrid approach almost always gives you the biggest bang for your buck.

Here’s why: you can reserve the more complex and investment-heavy predictive tools for your absolutely critical assets—the ones where failure would be a catastrophe. Think central chillers, main elevators, or backup generators. For everything else, like lighting systems or secondary pumps, you can stick with simple, cost-effective preventive schedules. This balanced approach protects your most important systems without blowing the budget.

Key Insight: A hybrid strategy isn't a compromise; it's smart optimization. You’re applying the right level of resources to the right level of risk, ensuring you get maximum reliability where it counts the most.

What’s the First Step to Get Started with Predictive Maintenance?

Before you even think about technology, your first move has to be an asset criticality assessment. You need to know exactly which pieces of equipment would cause the most damage—financially or operationally—if they went down.

Once you have that list, don’t try to boil the ocean. Pick just two or three of those high-priority assets for a small pilot program. This lets you test the waters, prove the ROI to your stakeholders, and work out the kinks on a manageable scale before you commit to a full-scale rollout.

Ready to build a maintenance strategy backed by a rock-solid network? Clouddle Inc provides managed networking and monitoring services that create the stable, secure foundation your predictive maintenance program needs to succeed. Find out how Clouddle can support your goals.