Think of a work order management system as the digital nerve center for all your property's maintenance and operational tasks. It's the system that takes the mess of sticky notes, chaotic email chains, and outdated spreadsheets and organizes it all into one clear, trackable workflow, from the initial service request to the final report.

From Manual Chaos to Digital Control

Trying to manage property operations with paper and phone calls is like trying to direct air traffic with signal flags. It's a recipe for disaster. Requests disappear into a black hole, important tasks get forgotten, and you never have a clear picture of who’s working on what or when it will actually get done. This isn't just frustrating; it's incredibly inefficient and costly.

A work order management system brings order to that chaos. It becomes the single source of truth for your entire team, capturing every request, assigning it to the right person, and tracking its progress from start to finish. This shift is no longer a luxury—it’s a necessity for running a modern, efficient operation.

The numbers back this up. The global market for these systems was valued at a hefty USD 760.4 million in 2024 and is expected to rocket past USD 1.3 billion by 2030. This growth is fueled by a massive shift to cloud-based platforms that make this technology accessible to everyone. For a deeper dive into these numbers, you can check out the full market research from Grandview Research.

Before a system is in place, the daily reality is a constant struggle to keep up. After implementation, teams can finally get ahead. The table below paints a clear picture of this transformation.

Manual Chaos vs Digital Control

| Operational Area | Manual Process (The Old Way) | Work Order Management System (The New Way) |

|---|---|---|

| Request Intake | Phone calls, emails, verbal requests. Often lost or forgotten. | Centralized portal or app. Every request is captured and time-stamped. |

| Task Assignment | Guesswork. Calls or texts to see who's free. No skill matching. | Automated or manual assignment based on skills, location, and workload. |

| Tracking Progress | "Have you done that yet?" Constant follow-up calls and texts. | Real-time status updates are visible to everyone on a central dashboard. |

| Data & Reporting | Non-existent. No way to track trends, costs, or team performance. | Automated reports on everything from response times to asset history. |

| Accountability | Very low. It's easy for tasks to fall through the cracks. | High. Every action is logged, creating a clear audit trail. |

The difference is night and day. Moving to a digital system replaces guesswork and disorganization with data-driven clarity and control, allowing teams to work smarter, not just harder.

The Core Workflow of a Management System

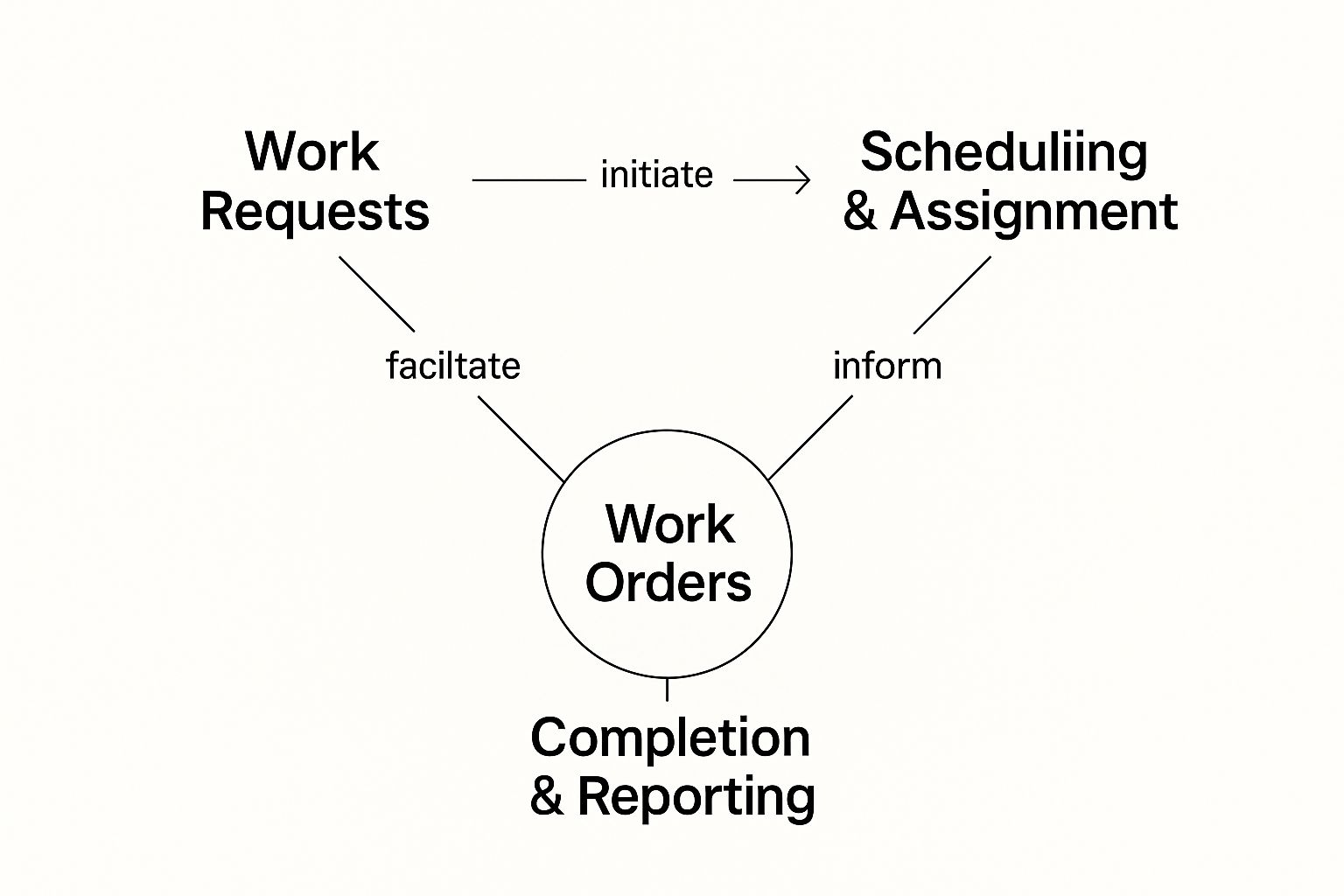

At its heart, any good work order system follows a simple, logical cycle. The goal is to make sure nothing gets missed and every step is documented.

Here’s what that looks like in practice:

- Step 1: Request Submission: A tenant, guest, or staff member reports an issue through a simple online portal or mobile app. No more lost sticky notes.

- Step 2: Work Order Creation: The system instantly converts that request into a formal work order, complete with a priority level, location, and detailed description of the problem.

- Step 3: Assignment & Scheduling: A manager (or the system itself) assigns the job to the best technician based on their skills, current location, and workload.

- Step 4: Execution & Tracking: The tech gets a notification on their phone, heads to the job, and updates the status in real-time as they work.

- Step 5: Completion & Reporting: Once the job is done, the work order is closed out. All the important data—like time spent and parts used—is automatically logged for future analysis.

This creates a seamless flow of information from the initial problem to the final solution.

As you can see, it's a closed-loop process. The data from every completed job feeds back into the system, helping you make smarter decisions about everything from staffing to preventative maintenance schedules.

Why Is This Shift So Important?

Bringing in a work order management system is about more than just getting organized. It’s a fundamental change in strategy—from being reactive to becoming proactive. Instead of constantly putting out fires, your team can start preventing them.

This transition fundamentally changes how a team operates. It moves them from a constant cycle of urgent, unplanned repairs to a structured environment of scheduled maintenance and predictable workflows. The result is longer-lasting equipment and lower long-term costs.

This proactive approach doesn't just save money. It directly impacts the experience of your tenants, guests, or residents, leading to much higher satisfaction and retention. It empowers your team to stop chasing problems and start solving them before they even happen.

Core Features That Streamline Operations

A modern work order management system is much more than a fancy digital to-do list. It’s an operational command center built to fix real-world problems. The best platforms have a set of core features that work in concert to make your entire workflow smoother, more transparent, and radically more efficient.

Think of it like the difference between a pit crew and a lone mechanic with a rusty toolbox. Both can fix a car, but the pit crew—with its coordinated roles, specialized tools, and real-time communication—gets the job done with precision and speed. The features in these systems bring that same level of coordination to your team.

Automated Dispatching and Intelligent Scheduling

Let's be honest, manual dispatch is messy. It’s a frantic scramble of phone calls, texts, and guesswork. Who’s the closest? Who actually knows how to fix this specific HVAC unit? This chaos burns precious time and sends the wrong people to the wrong jobs.

Automated dispatching changes all that. It acts like a seasoned dispatcher who knows your team inside and out, assigning the right job to the right person based on cold, hard logic.

- Skill-Based Routing: The system knows who’s certified for what. A complex boiler issue automatically goes to your senior specialist, not the new hire.

- Location Awareness: Using geolocation, it finds the closest available tech, slashing travel time and fuel costs. No more crisscrossing the city.

- Workload Balancing: It intelligently distributes tasks to prevent one person from getting buried while another sits idle. This keeps morale up and burnout down.

This move from chaotic to logical assignment means urgent issues get handled faster by the person best equipped to solve them.

Real-Time Status Tracking for Full Visibility

One of the biggest headaches in maintenance operations is the “black box.” A work order is submitted, a tech is assigned, and then… silence. Is it done? Did they even start? This uncertainty forces managers into a constant cycle of follow-up calls and emails.

Real-time status tracking smashes that black box wide open. It gives everyone a live dashboard showing the exact stage of every single work order—from “Assigned” and “In Progress” to “On Hold” or “Completed.”

This transparency is a game-changer. It eliminates the need for constant check-ins, freeing up managers to think strategically instead of playing phone tag. Everyone looks at the same screen and gets the same story.

For instance, a property manager can see that a technician has arrived on-site and started a repair. That technician can then update the status to “Awaiting Parts,” which instantly pings the procurement team. This seamless information flow keeps projects from stalling. For a great example of this in action, look at how the top fleet management software has perfected dispatch and live tracking for vehicles and assets on a massive scale.

Mobile Access That Empowers Technicians

Your team does its work out in the field, not chained to a desk. Paper work orders are slow, easy to lose, and create a massive communication gap between the field and the office.

Mobile access puts the full power of the system right into your technicians' hands through a smartphone or tablet. They’re no longer tethered to the home base; they’re equipped with everything they need to get the job done right, right where they are.

With a good mobile app, a technician can:

- Get new work orders instantly, without driving back to the office.

- Pull up detailed instructions, checklists, and manuals right on site.

- Snap photos and videos to document a problem or show a completed repair.

- Log time and parts used on the spot, making your cost tracking dead-on accurate.

This isn’t just a nice-to-have; it's essential. Giving your team mobile tools empowers them to work faster and smarter, and the rich data they capture feeds back into the system, making the whole operation more intelligent. It’s a foundational piece of the puzzle for anyone serious about finding out how to improve operational efficiency.

Asset History Logs That Prevent Breakdowns

Picture this: a technician is called to fix a rooftop AC unit for the third time this quarter. Without any history, they might just repeat the same quick fix the last person tried, never solving the root cause. This cycle of repeat failures is a huge drain on time and money.

Asset history logs put an end to that cycle. The system creates a comprehensive digital file on every piece of equipment you manage. Every repair, inspection, and part replacement is automatically documented.

Before even touching a wrench, a tech can pull up the asset’s full history to see:

- Every past repair and the notes left by previous technicians.

- How often it breaks down, flagging equipment that needs to be replaced.

- Warranty details and original installation dates.

This context allows for far smarter maintenance. Instead of just patching symptoms, your team can spot underlying issues and perform true preventative work, ultimately extending the life of your assets and avoiding those costly emergency calls.

How Different Industries Benefit from This System

A work order management system isn’t a one-size-fits-all solution. Its real power comes to light when you see how it solves the unique problems and pressures of different industries. While the basic idea is always about organizing tasks, the results can look wildly different depending on where it’s used.

Think about it this way: for a hotel, the goal is stellar guest satisfaction. For an apartment complex, it's all about tenant retention. And for a commercial building, the focus is on keeping operations running smoothly while controlling costs.

Knowing these differences is the key to getting the most out of the technology.

Hospitality: Perfecting the Guest Experience

In the hospitality world, your reputation is your currency. A single scathing online review about a broken air conditioner or a leaky showerhead can seriously damage future bookings. The guest experience is everything, and a work order system is one of the most important tools you have to protect it.

The moment a guest reports a problem, the clock is on. The old way of doing things—a frantic phone call to a maintenance tech who then has to track down the right room—is just too slow and full of potential missteps.

With a digital system, a front desk clerk can log a work order instantly. That request is then automatically sent to the right technician’s phone, complete with all the details: room number, a clear description of the issue, and even the guest’s name. They know what they’re walking into before they even knock on the door.

This leap in efficiency brings some very real benefits:

- Faster Response Times: Problems get fixed in minutes or hours, not days. You solve the issue long before a guest's patience runs out.

- Improved Guest Satisfaction: Turning a potential negative into a positive with a quick, professional fix can earn you better reviews and loyal customers.

- Proactive Maintenance: Housekeeping can snap a picture of a flickering lightbulb or a dripping sink during their rounds, creating a work order that gets resolved before a guest ever notices.

By shifting your maintenance from a reactive, fire-fighting exercise to a swift, proactive operation, hotels can directly boost their guest satisfaction scores. A smooth, hiccup-free stay is what drives repeat business and those coveted five-star reviews.

Multi-Family Properties: Boosting Tenant Retention

For property managers of multi-family buildings, the game is all about keeping residents happy and units full. High tenant turnover is a financial drain, between the lost rent, marketing spend, and make-ready costs. One of the quickest ways to lose a good tenant? Botching their maintenance requests.

A work order management system brings much-needed order to the chaos. When a tenant submits a request for a running toilet through an online portal, it doesn’t just vanish into an email inbox. It’s tracked.

The system creates a time-stamped, digital paper trail, which means accountability. A property manager can assign the job, see its status in real-time, and send updates to the tenant right through the platform. That kind of transparency builds trust and makes residents feel heard.

Beyond individual units, these systems are also crucial for managing preventive maintenance on big-ticket items like boilers, elevators, and roofing. Getting ahead of those jobs prevents the kind of major failures that can disrupt the lives of everyone in the building. It’s a core piece of any modern property management tech stack for a reason. https://clouddle.com/blog/property-management-tech/

Commercial Real Estate: Driving Operational Efficiency

When you move into commercial real estate—office buildings, retail centers, industrial parks—the priorities shift again. Now, it's about controlling operational costs, maximizing the lifespan of your assets, and staying compliant. The equipment is bigger, more complex, and far more expensive. We’re talking massive HVAC systems, fire suppression equipment, and backup generators.

For a tenant, downtime isn't just an annoyance; it can shut down their business.

A work order system acts as the command center for maintaining these critical assets. It allows facility managers to schedule all the routine inspections and preventive work needed to keep expensive equipment running longer, which drastically reduces the chance of a costly, middle-of-the-night emergency.

This is especially critical in specialized environments like restaurants, where a down freezer or a broken oven means lost revenue. In fact, many successful strategies to improve restaurant operations are built around meticulously planned maintenance workflows.

For commercial operators, the advantages are clear:

- Reduced Operational Costs: It's always cheaper to maintain equipment than it is to replace it after a catastrophic failure.

- Vendor Management: The system helps track jobs assigned to outside vendors, making sure you’re getting what you pay for and that SLAs are being met.

- Compliance and Safety: You get a complete digital audit trail for every safety inspection and required maintenance task—essential for regulators and insurance providers.

No matter the industry, a work order management system ultimately does the same thing: it replaces confusion with clarity, chaos with control, and guesswork with good data.

Calculating the Financial Return on Your Investment

Operational improvements are great, but let's be honest—for any business, the real question comes down to the bottom line. How does a work order management system actually pay for itself? Answering this means calculating its Return on Investment (ROI), which is the key to building a rock-solid business case and finally ditching those outdated manual methods.

The financial upside isn't just about trimming a few expenses here and there. It’s about creating real, measurable value that ripples across your entire operation. This value shows up in two distinct ways, and you need to look at both to get the full picture.

Hard Cost Savings You Can Actually Measure

Hard savings are the most straightforward benefits. These are the concrete numbers you can plug into a spreadsheet—the direct reductions in what you spend to keep things running. Think of them as the dollars you immediately stop bleeding.

- Reduced Technician Overtime: Smart scheduling and dispatching the nearest available technician means less time wasted on the road. More jobs get done during regular hours, which puts a major dent in those costly overtime bills.

- Optimized Inventory Spend: The system keeps a running tab on every part used for every job. This stops you from over-ordering supplies that just sit on a shelf and ends those last-minute, premium-priced runs to the store for a part you didn't realize you were out of.

- Lower Emergency Repair Costs: Proactive, preventative maintenance is a game-changer. The system ensures it actually happens, catching small issues before they snowball into catastrophes. It's the difference between a $150 belt replacement and a $15,000 motor burnout.

These direct savings are the bedrock of your ROI calculation. They provide clear, undeniable proof of the system's financial worth right from the start.

The real power of a work order management system is its ability to turn data into savings. By logging every action, part, and hour, it gives you the visibility needed to identify and eliminate financial waste that was previously invisible.

The Powerful Impact of Soft Benefits

While they're a bit harder to pin a precise dollar amount on, "soft" benefits can have a massive and lasting impact on your company's financial health. These are the gains you see in productivity, reputation, and the longevity of your assets—all of which drive long-term growth.

- Improved Tenant and Guest Retention: Faster responses and clear communication create happier tenants and guests. Since a 5% increase in customer retention can boost profits by over 25%, this is an incredibly powerful financial lever.

- Higher Staff Productivity: When technicians aren't buried in paperwork or driving back and forth to the office for their next assignment, they simply get more done. This efficiency boost lets your current team handle a bigger workload without you needing to hire more people.

- Extended Equipment Lifespan: Consistent, documented maintenance keeps your big-ticket assets—like HVAC units, boilers, and elevators—running smoothly for much longer. Pushing off a major capital expense by even a year or two can have a huge positive effect on your cash flow.

This shift toward system-driven management isn't just a niche trend; it's exploding globally. The Work Order Management Systems market was valued at USD 3.5 billion in 2024 and is on track to hit USD 8.2 billion by 2033. This shows just how many organizations are investing to capture these exact benefits. You can dig into more of this data by reading the full market report from Verified Market Reports.

Ultimately, these benefits are crucial because they directly boost revenue and cut expenses, which is the core of your Net Operating Income. To learn more about that, check out our guide on calculating Net Operating Income.

A Simple ROI Calculation Framework

To help you start thinking about the numbers for your own business, here’s a straightforward framework. It breaks down the key areas where you’ll see a financial impact from implementing a work order management system.

| ROI Factor | Description | Example Metric to Track |

|---|---|---|

| Labor Efficiency | The increase in work completed by your existing team without adding headcount or overtime. | – Number of work orders completed per technician per week. – Reduction in average overtime hours per month. |

| Inventory Cost Reduction | Savings from eliminating rush orders, reducing carrying costs of excess parts, and minimizing waste. | – Percentage decrease in emergency parts purchases. – Total value of on-hand inventory over time. |

| Asset Longevity | The financial value of extending the life of major equipment and deferring costly replacements. | – Reduction in major equipment failures per year. – Average age of key assets at replacement. |

| Customer Retention | The revenue impact of keeping more tenants, guests, or clients due to improved service levels. | – Tenant/guest turnover rate. – Renewal rates for service contracts. |

By tracking metrics in these four areas, you can build a powerful and realistic projection of how quickly the system will not only pay for itself but also start generating a positive return for your business.

Your Practical Roadmap to a Smooth Rollout

Let’s be honest: rolling out new software can be a headache. The key to successfully adopting a new work order management system isn't just picking the right tech—it's having a smart strategy behind it. Simply buying a subscription and telling your team to "use it" is a surefire way to get low adoption and a wasted investment.

Think of it like building a house. You wouldn't just start throwing up walls without a solid blueprint, a strong foundation, and a clear plan for the plumbing and electrical. A successful software launch needs that same level of careful planning to make sure the transition is smooth and your team is on board from day one.

Step 1: Discovery and Picking a Partner

Before you even look at a single demo, you need to look inward. This first phase is all about understanding what you're actually trying to fix. What are your biggest headaches right now? Are you drowning in disorganized email requests, struggling to track asset history, or bleeding money on reactive, emergency repairs? Nailing down your specific pain points is the most important thing you'll do.

Once you have that clarity, you can start checking out vendors. Look past the flashy sales pitches and focus on how a platform solves your specific problems. It's helpful to know you're stepping into a pretty dynamic market. The Work Order Management Market was estimated at USD 0.83 billion in 2024, and the best players are all focused on cloud-based, mobile-first solutions. As you explore, you're tapping into some seriously powerful tools. Discover more market insights from KBV Research.

A few key actions for this phase:

- Create a "Must-Have" vs. "Nice-to-Have" List: What features are absolutely non-negotiable for your operations? What would just be a cool bonus?

- Talk to Your Team: Get input from the technicians and managers who will be in the system every single day. Their perspective is gold when it comes to choosing something that’s actually easy to use.

- Request Targeted Demos: Don't sit through a generic presentation. Ask vendors to show you exactly how their software solves one of your top three problems.

Step 2: Data Migration and System Setup

So, you’ve picked your partner. Now comes the part that can feel a little overwhelming: getting all your existing information into the new system. But look at it this way—it's the perfect opportunity for a spring cleaning. Resist the urge to just dump messy, old spreadsheets into a shiny new interface. This is your chance to standardize your data, archive outdated records, and make sure your asset lists are actually accurate.

This is also when the more technical setup happens. You'll be configuring who can see and do what (user roles), setting up automated workflows, and customizing fields to use the language your team already uses. A good vendor will walk you through this, but you need a point person on your side to lead the charge.

Pro Tip: Appoint an internal project champion. Find someone on your team who's genuinely excited about the new system and can be the go-to person for questions. Having this single point of contact is absolutely crucial for keeping the implementation from going off the rails.

Step 3: Onboarding and Training Your Team

This is where the rubber meets the road. Your goal is to make your team feel like this new tool is a superpower, not another chore. Good training doesn't just show them which buttons to click; it shows them how the system makes their jobs easier. Think less paperwork, instant access to info on the fly, and clearer communication with the front office.

Forget about one long, boring training session that everyone dreads. Break it up into smaller, role-specific chunks. Your techs need to become masters of the mobile app, while your managers need to know how to pull reports from the dashboard. Hands-on practice isn't optional—it's essential.

Step 4: The Pilot Program and Full Launch

Before you flip the switch across your entire portfolio, start small with a pilot program. Pick one building, one team, or even just one type of work order to test the new system in a real-world but controlled setting. This is your safety net, allowing you to find and fix any weird quirks with minimal disruption.

Use this pilot to get honest feedback. What’s working great? What’s confusing people? Smoothing out these little bumps early on prevents them from turning into major roadblocks when you go live everywhere.

Here’s a simple, phased approach for a successful deployment:

- Select a Pilot Group: Choose a team that’s generally open to new tech or a property where you can easily check in and monitor how things are going.

- Define Success: What does a "win" look like for this pilot? Is it a faster average response time? Positive feedback from the techs? Know what you're measuring.

- Gather Feedback: Actively ask your pilot users for their thoughts. Listen to what they say and make adjustments based on their experience.

- Launch Company-Wide: Once you’ve worked out the kinks, you’re ready for the full rollout. And the best part? Your pilot group now becomes your internal cheerleading squad.

Got Questions? We’ve Got Answers.

Switching to a new system always brings up a few questions. It’s a big decision, and you need to be sure it’s the right one. Here are some of the most common things we hear from operators like you, with straight-up answers to help you make your choice.

Will This System Talk to Our Accounting Software?

Yes, it absolutely should. Modern work order platforms are built to connect with the tools you already use. Most have ready-to-go integrations for popular software like QuickBooks or can easily link up with larger enterprise systems through an API.

This connection is a game-changer. It means when a work order is closed out, an invoice can be generated automatically. It lets you track maintenance costs against specific properties or even individual pieces of equipment, so you know your true expenses. You're eliminating the soul-crushing (and mistake-filled) task of double-data entry. Just make sure to ask any potential provider about their specific integrations to guarantee a smooth link between your operations and your finances.

What Happens When My Business Gets Bigger?

This is where cloud-based systems really shine. They're designed to grow right alongside you. Forget the old days of buying new servers or facing massive upgrade projects.

As you add more properties or bring on more staff, you can simply adjust your subscription. You can add more users, track more assets, and expand to new locations with just a few clicks. It’s a flexible approach that lets you start with what you need right now and scale up your features and user count as you expand. No growing pains, no starting over from scratch.

A scalable work order management system supports your growth instead of getting in the way. The tool you choose today should still be a perfect fit when your business has doubled in size.

How Do I Get My Maintenance Team to Actually Use This Thing?

This is the most important question of all. The fanciest software in the world is worthless if your team won't use it. The secret is to make sure they see it as a tool that helps them, not another task you're piling on.

Getting your team on board comes down to a few simple things:

- Make it Mobile-First and Dead Simple: Your techs are on their feet, not behind a desk. They need an app that's as easy to use as their favorite social media app. If it’s clunky, they’ll find a way around it.

- Give Them a Seat at the Table: Involve your lead technicians in the demo and selection process. When they help pick the tool, they become its biggest champions.

- Show Them "What's In It For Me?": Frame the training around how it makes their job easier. No more hunting for paperwork. Instant access to an asset's repair history. Clear instructions and photos for every job, right on their phone.

When your team sees the software as a powerful tool in their own toolbox, adoption stops being a challenge and starts becoming a natural part of a better workflow.

Ready to replace operational chaos with streamlined control? The team at Clouddle Inc specializes in creating integrated technology solutions that empower property managers and business owners to work smarter. Discover how our managed services can bring clarity and efficiency to your operations by visiting us at https://www.clouddle.com.